Device for transferring eggs

A transfer device and transfer technology, applied in packaging, packaging food, packaging eggs, etc., can solve problems such as wasting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

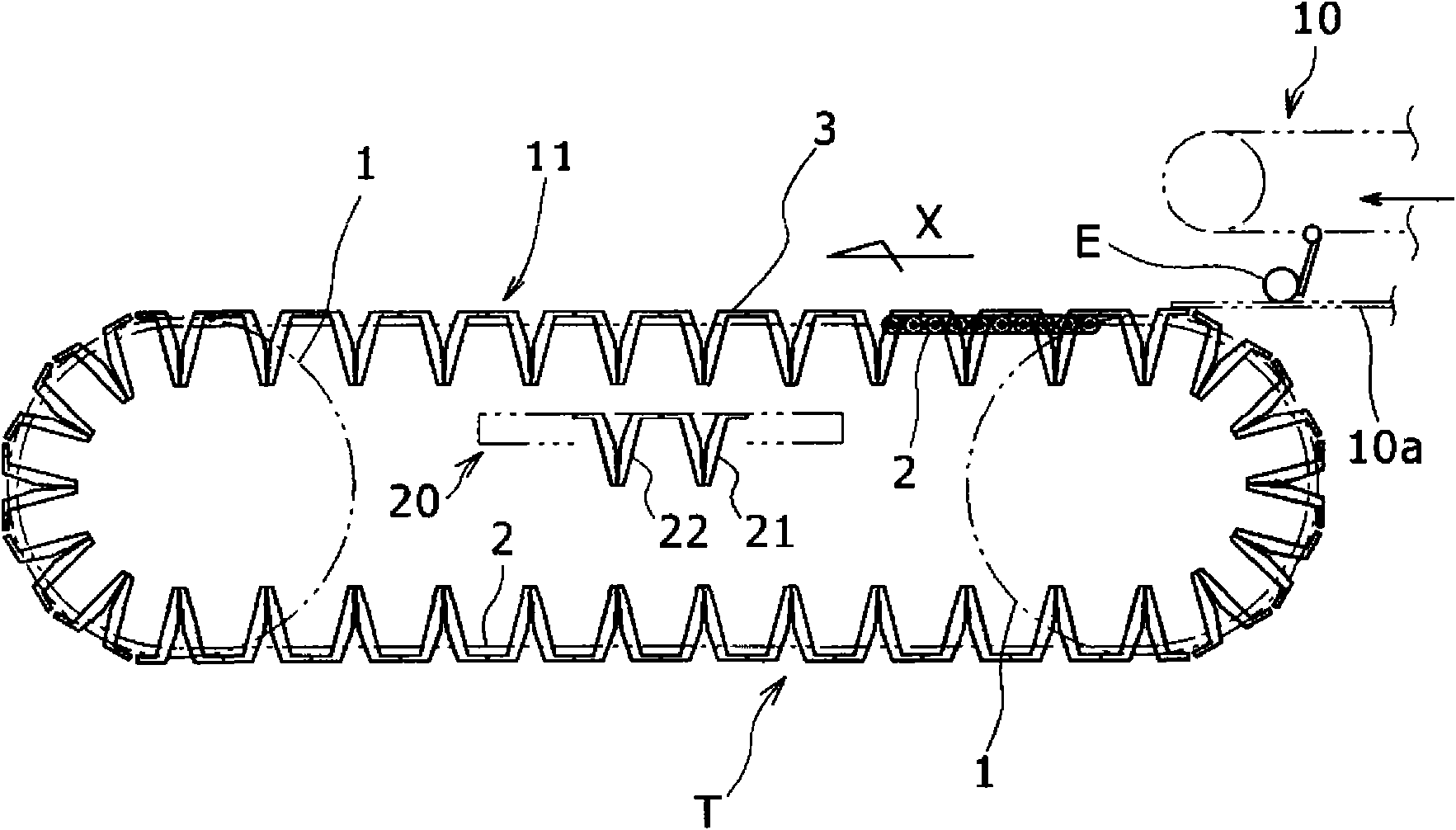

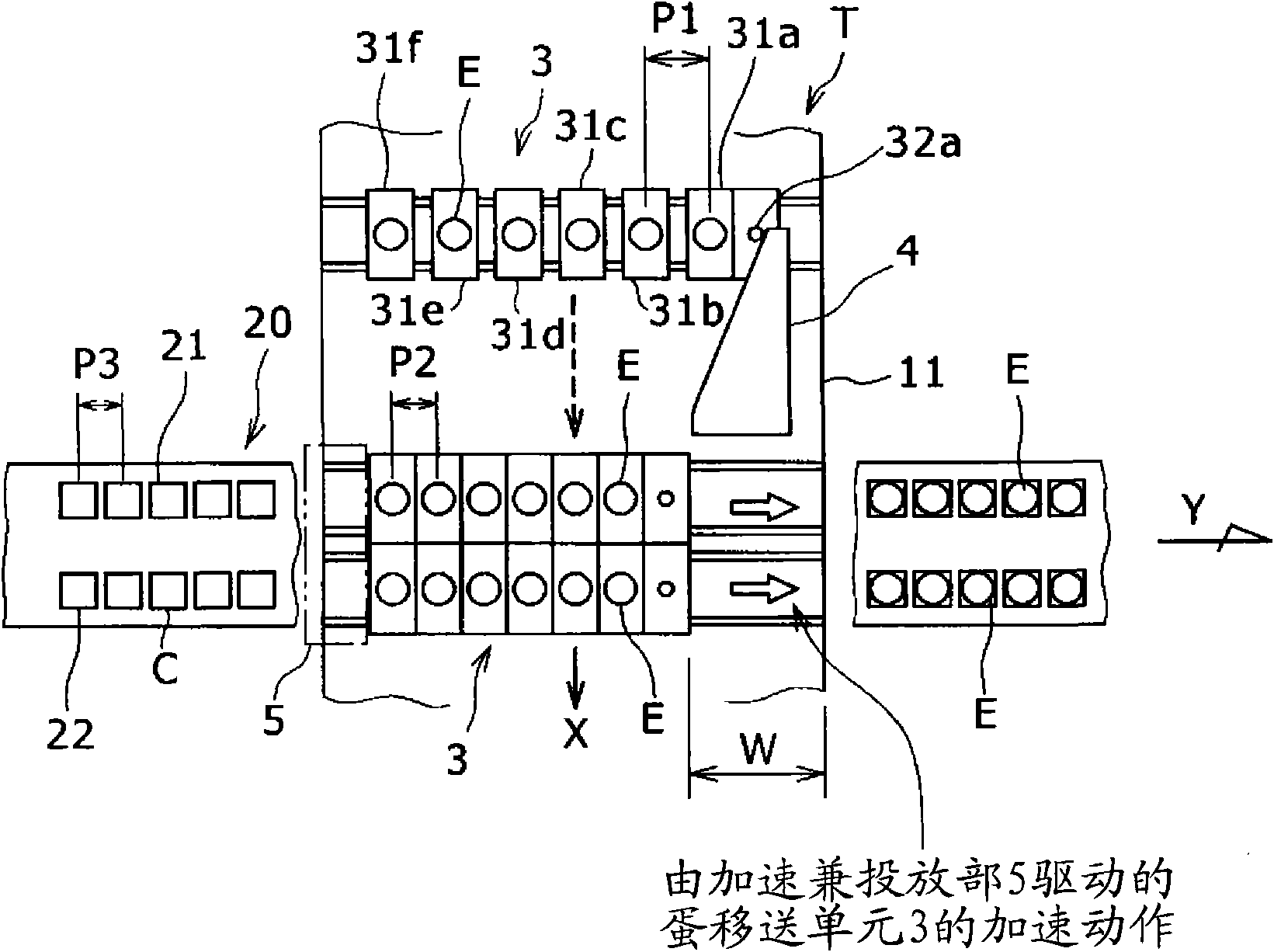

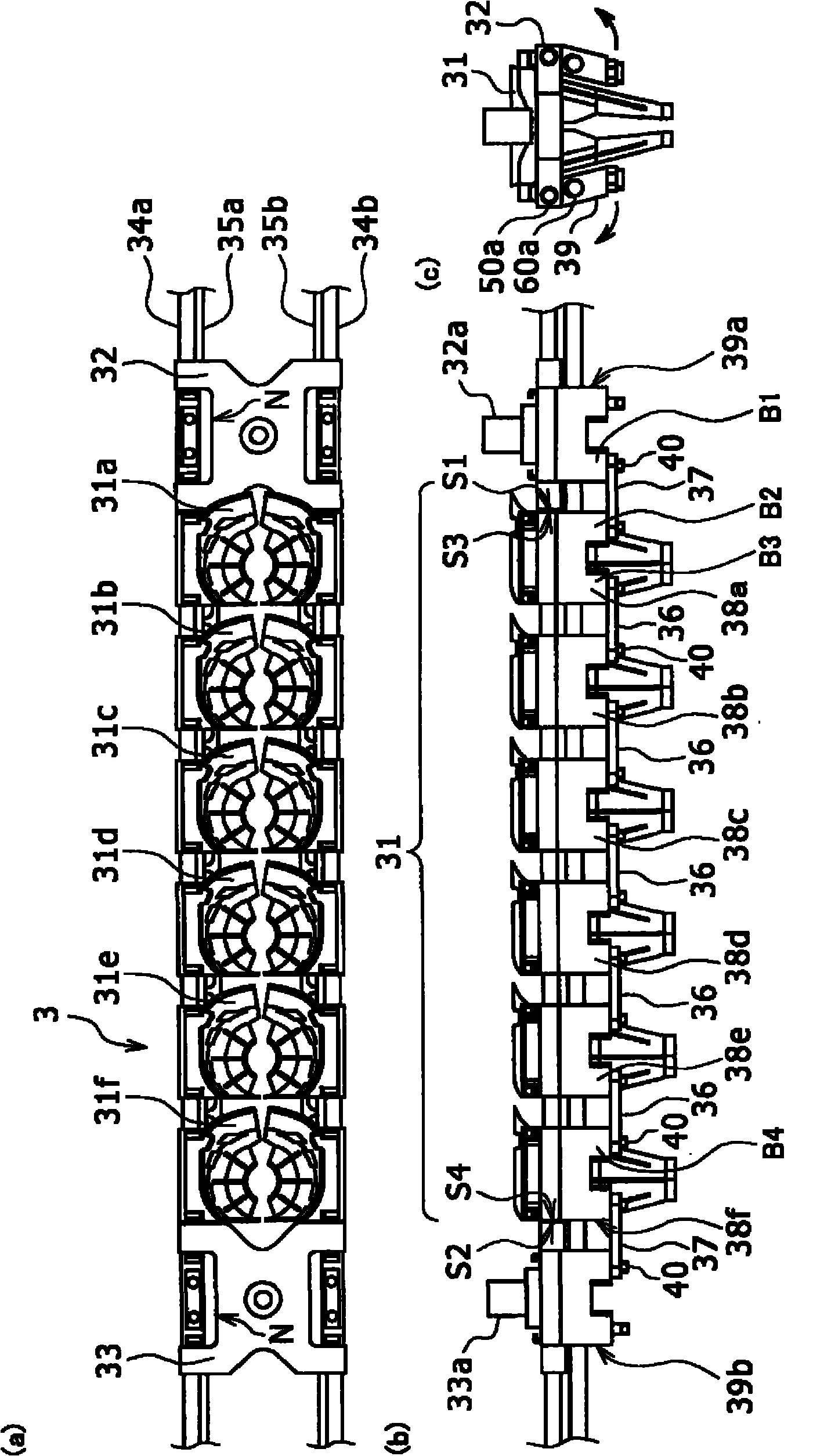

[0034] Next, as Embodiment 1 of this invention, the transfer apparatus T of an egg is demonstrated based on drawing. figure 1 It is a schematic side view of the egg transfer device T of the first embodiment of the present invention, figure 2 is a schematic top view of the egg transfer device T, image 3 It is a concrete structural diagram of the egg transfer unit 3 which is the storage container row of the egg transfer apparatus T. also, Figure 4 is a perspective view of the egg transfer unit 3, Figure 5 It is a partial concrete configuration diagram of the egg transfer unit 3 .

[0035] Such as figure 1 As shown, the egg transfer device T of this embodiment is roughly composed of an endless conveyor belt 11 arranged in the same direction as the conveying direction of the predetermined conveyor belt 10 and an egg along the conveying direction (X direction) intersecting with the endless conveyor belt 11 . The next-stage conveyor belt 20 arranged in the direction (orthog...

Embodiment approach 2

[0076] Next, an egg transfer device T according to Embodiment 2 of the present invention will be described with reference to the drawings. Figure 8 A schematic plan view showing an egg transfer device T according to Embodiment 2 of the present invention, and figure 2 The same parts of the illustrated egg transfer device T are denoted by the same reference numerals, and description thereof will be omitted.

[0077] The basic structure of the egg transfer apparatus T of this embodiment is substantially the same as the egg transfer apparatus T of 1st Embodiment mentioned above. Such as Figure 8 As shown, the egg transfer device T of this embodiment is composed of an endless conveyor belt 11 , an acceleration unit 6 , a delivery unit 7 arranged at a position opposite to the acceleration unit 6 , and a next-stage conveyor belt 20 .

[0078] if compare Figure 8 and figure 2 It can be seen that the egg transfer device T of this embodiment does not have the adjustment plate 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com