Sludge vitrifaction curing treatment process

A technology of solidification treatment and vitrification, which is used in dewatering/drying/concentrating sludge treatment, pyrolysis treatment of sludge, etc., can solve problems such as poisonous sludge siege, and achieve the effect of stabilization treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

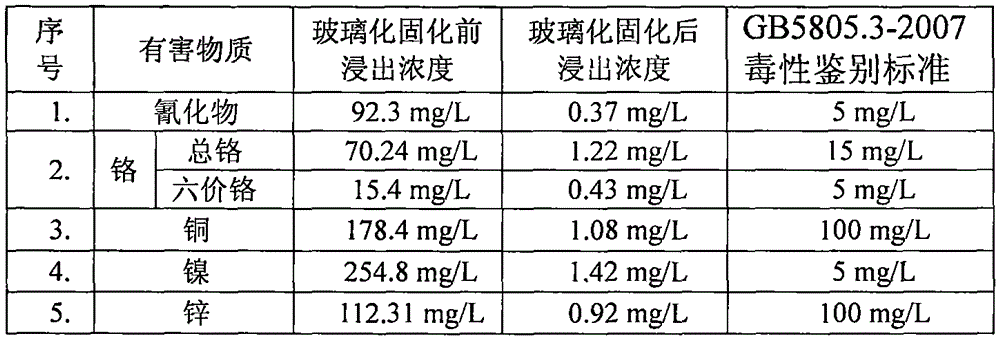

[0008] Embodiment 1 electroplating sludge

[0009] Table 1 Comparison of leaching concentrations of harmful substances before and after vitrification

[0010]

[0011] From the analysis of the data in the above table, it can be seen that this process can effectively remove various harmful substances in the electroplating sludge, and the final product is subjected to toxicity leaching tests according to GB5805.3-2007, which meets the national environmental protection requirements and can be directly landfilled.

Embodiment 2

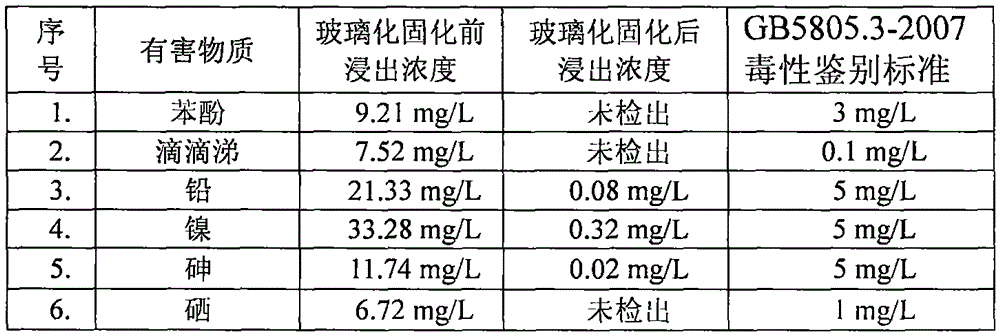

[0012] Example 2 Shenhua Baotou Coal Chemical Industry Branch Sewage Treatment Plant Sludge

[0013] Table 2 Comparison of leaching concentration of harmful substances before and after vitrification solidification

[0014]

[0015] From the analysis of the data in the above table, it can be seen that this process can effectively remove various harmful substances in the sludge of the sewage treatment plant of Shenhua Baotou Coal Chemical Company. directly to landfill. Note: The organic matter in the sludge is completely carbonized and decomposed, while the inorganic matter is fixed in the solid particles in the form of glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com