Multiple-roller type high-pressure electrostatic separation method for recovering waste and old printed circuit boards

A printed circuit board and high-voltage electrostatic technology, which is applied in the field of multi-roller high-voltage electrostatic separation, can solve the problems of increasing the processing capacity and the stability of the roller sorter, and achieves improved processing efficiency, stable processing process, and high recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Minimize intermediate products

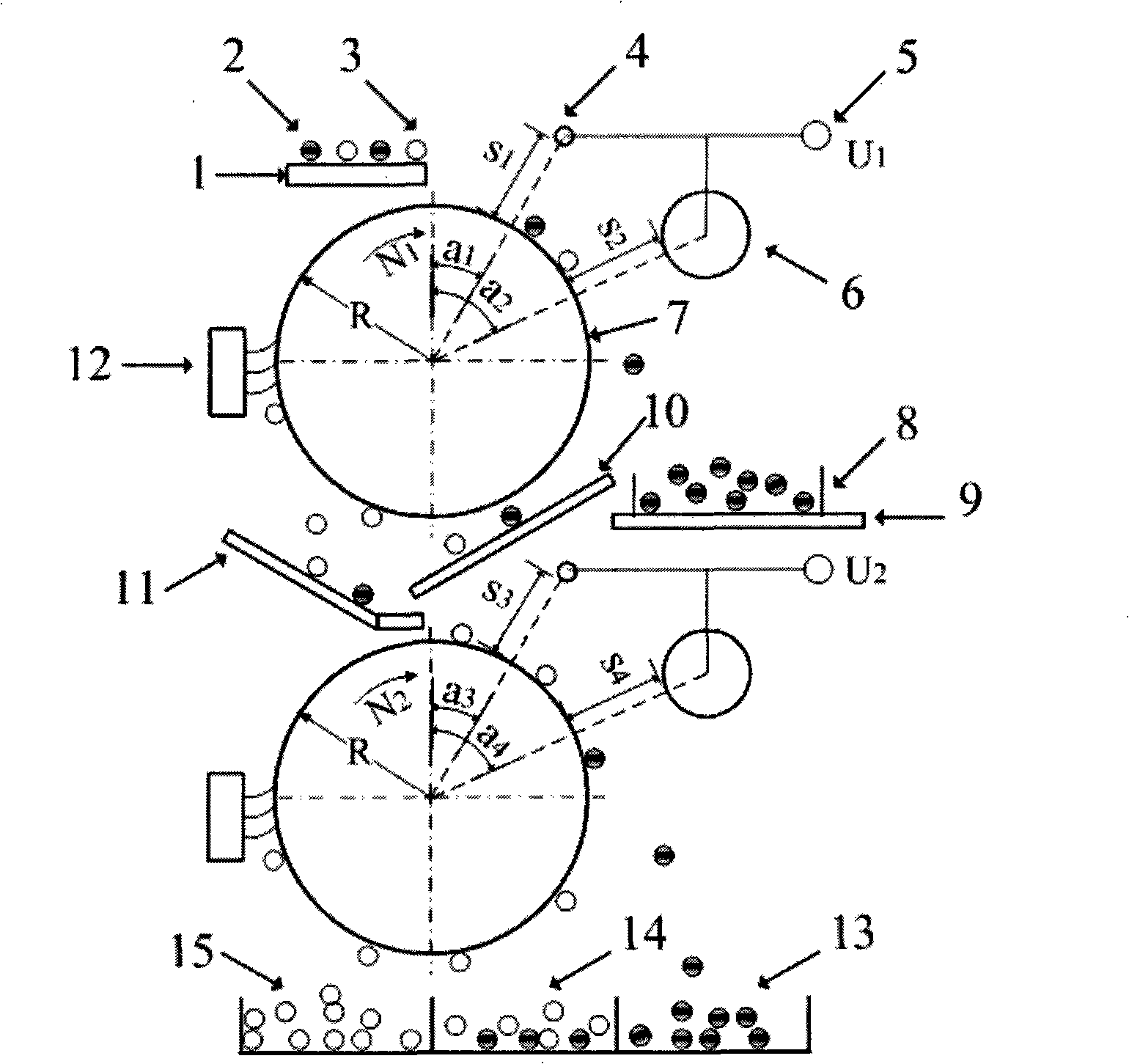

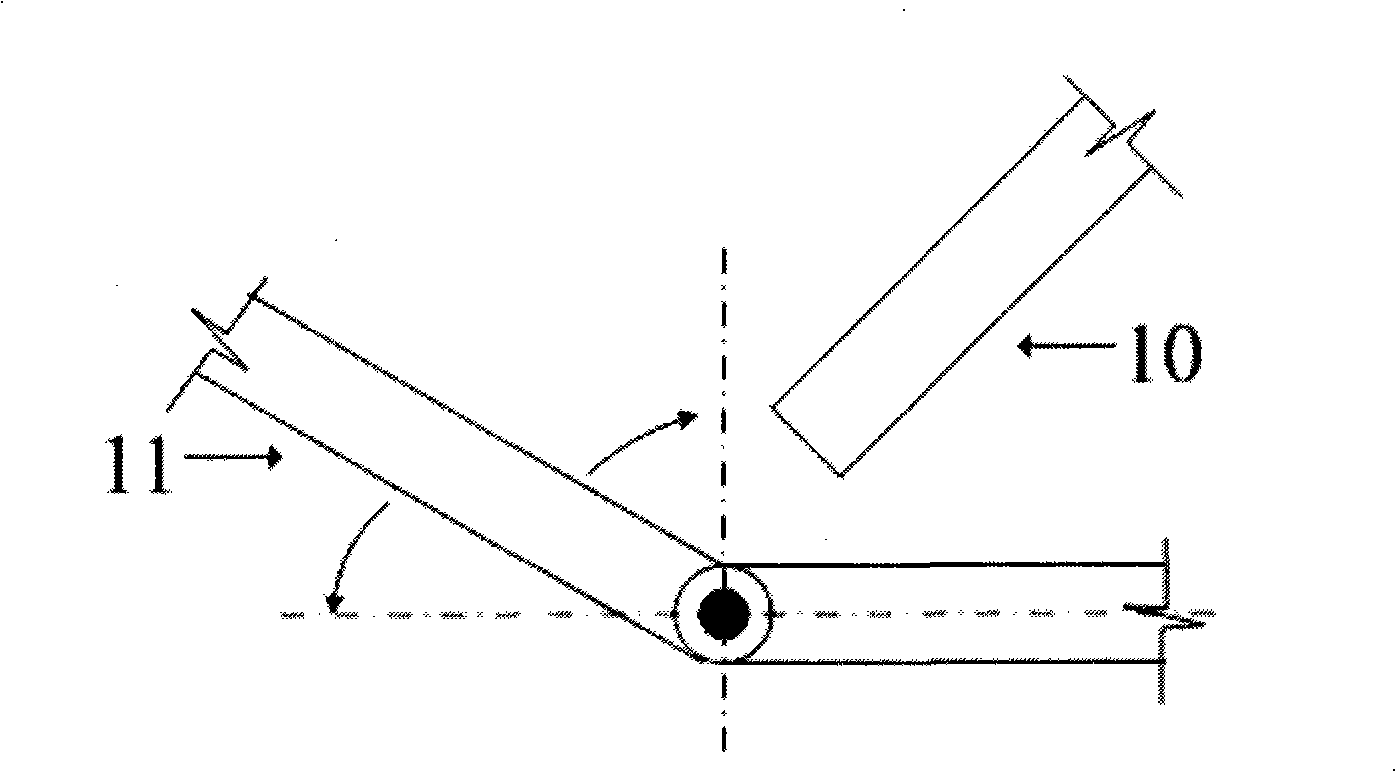

[0026] The broken waste circuit board particles with a particle size of 0.3-0.45mm were used as samples. Two roller separation devices with the same structure are arranged in an array in the vertical direction to form a double roller separation device, and two slides with adjustable angles are arranged between the roller separation devices.

[0027] During separation, the metal-nonmetal mixed particles of the broken waste circuit board enter the first-stage separation device from the feeding trough through the electromagnetic vibrating feeder, and are evenly spread on the surface of the grounding roller, and the roller speed is N 1 It is 60rpm, and then enters the high-voltage electrostatic field formed by corona electrodes, static electrodes and roller electrodes, where the parameters are: voltage U 1 20kV, the distance between the corona electrode and the roller s 1 70mm, the angle α with the vertical center line of the roller 1 25°...

Embodiment 2

[0030] Maximize metal production

[0031] The broken waste circuit board particles with a particle size of 0.3-0.45mm were used as samples. A double-roller separation device is adopted. When separating, the mixed particles enter the first-stage separation device through the electromagnetic vibrating feeder, and are evenly spread on the surface of the ground roller (speed N 1 is 90rpm), and then enters the corona electrode (voltage U 1 30kV, spacing s 1 is 60mm, the included angle α 1 The ionization region formed by 30°). In this region, metallic particles are charged differently from non-metallic particles. The former is at the high voltage static electrode (voltage U 1 30kV, spacing s 2 is 90mm, angle α 2 65°) produces an electrostatic attraction, causing it to detach from the surface of the roller and fall into the metal collection area. The latter is close to the surface of the roller due to the effect of the image force, and moves with the roller until it is brush...

Embodiment 3

[0034] Maximize throughput

[0035] The broken waste circuit board particles with a particle size of 0.3-0.45mm were used as samples. A double-roller separation device is adopted. When separating, the mixed particles enter the first-stage separation device through the electromagnetic vibrating feeder, and are evenly spread on the surface of the ground roller (speed N 1 is 80rpm), and then entered by the corona electrode (voltage U 1 25kV, spacing s 1 is 60mm, the included angle α 1 The ionization region formed by 28°). In this region, metallic particles are charged differently from non-metallic particles. The former is at the high voltage static electrode (voltage U 1 25kV, spacing s 2 is 80mm, the included angle α 2 Under the action of 72°), an electrostatic attraction is generated, causing it to detach from the surface of the roller and fall into the metal collection area. The latter is close to the surface of the roller due to the effect of the image force, and mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com