Two-stage countercurrent washing medicament addition stabilization combined restoration method of chromium polluted soil

A chromium-contaminated soil and countercurrent washing technology is applied in the field of contaminated soil remediation and treatment, which can solve the problems of large water consumption, incomplete removal of hexavalent chromium, heavy water treatment burden, etc., to reduce water consumption, avoid incomplete removal, and operate easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

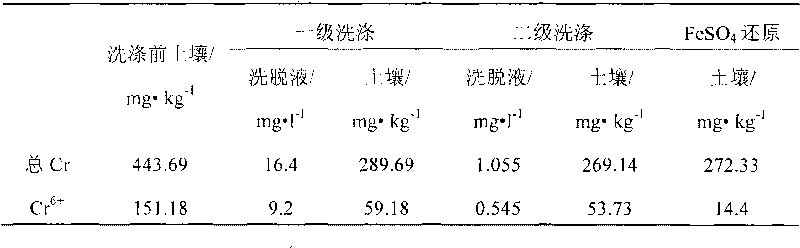

Embodiment 1

[0024] Take the polluted soil around the chromium slag dump of a chromium salt chemical plant in Haibei, Qinghai as an example. The chemical plant produces sodium alum (Na 2 Cr 2 o 7 2(H 2 O)) about 4,000 tons, 48,000 cubic meters of chromium slag have been accumulated and simply piled up. The simple stacking of chromium slag has seriously polluted the soil and groundwater around the chemical plant. The soil used in this example is sandy loam, the total chromium content in the soil is 443.69 mg / kg, and the hexavalent chromium content is 151.18 mg / kg.

[0025] Proceed as follows:

[0026] (1) Air-dry the soil sample, remove large rocks, tree roots, paper and other substances;

[0027] (2) Take 50g of soil, use the waste water from the secondary washing to carry out the primary washing according to the liquid-solid ratio of 10:1, shake at room temperature (20°C) for 40min, and dry the soil naturally after solid-liquid separation;

[0028] (3) Take 30 g of the soil after the...

Embodiment 2

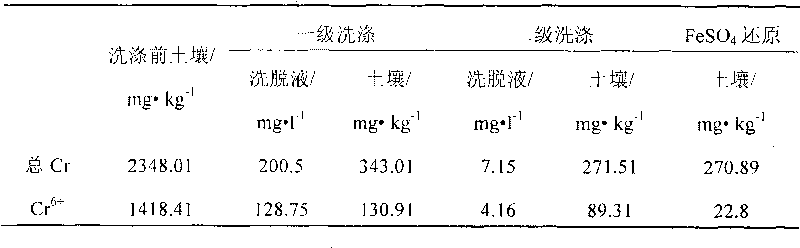

[0034] Take the polluted soil around the chromium slag dump of a chromium salt chemical plant in Huangzhong, Qinghai as an example. The soil of the site belongs to silty loam. The total chromium content in the soil is 2348.01mg / kg, and the hexavalent chromium content is 1418.41mg / kg.

[0035] Proceed as follows:

[0036] (1) Air-dry the soil sample, remove large rocks, tree roots, paper and other substances;

[0037] (2) Take 50g of soil, use the waste water from the secondary washing to carry out the primary washing according to the liquid-solid ratio of 10:1, shake at room temperature (20°C) for 40min, and dry the soil naturally after solid-liquid separation;

[0038] (3) Take 30 g of the soil after the first-level washing, and carry out the second-level washing with clean water that has been treated up to the standard at a liquid-solid ratio of 10:1, shake at room temperature (20° C.) for 40 minutes, and separate the solid and liquid;

[0039] (4) Take 20g of the soil aft...

Embodiment 3

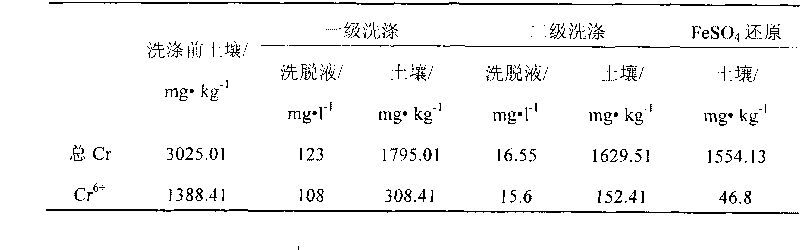

[0044] Taking the polluted soil around the chromium slag dump of a chromium salt chemical plant in Qingdao as an example, the soil sample belongs to cohesive loam. The total chromium content in the sample was 3025.01mg / kg, and the hexavalent chromium content was 1388.41mg / kg.

[0045] Proceed as follows:

[0046] (1) Air-dry the soil sample, remove large rocks, tree roots, paper and other substances;

[0047] (2) Take 50g of soil, use the waste water from the secondary washing to carry out the primary washing according to the liquid-solid ratio of 10:1, shake at room temperature (20°C) for 40min, and dry the soil naturally after solid-liquid separation;

[0048](3) Take 30 g of the soil after the first-level washing, and carry out the second-level washing with clean water that has been treated up to the standard at a liquid-solid ratio of 10:1, shake at room temperature (20° C.) for 40 minutes, and separate the solid and liquid;

[0049] (4) Take 20g of the soil after second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com