Acrylon production waste water treatment method

A treatment method and technology for producing wastewater, which is applied in textile industry wastewater treatment, biological water/sewage treatment, sustainable biological treatment, etc., can solve the problems of long wastewater treatment process, loss of activity, high content of suspended solids, etc., to improve microbial Effect of activity and wastewater treatment, reduction of treatment costs, and optimization of operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]An acrylic fiber factory adopts a one-step wet spinning process of polymerization and spinning in sodium thiocyanate solution phase and a two-step wet spinning process of suspension polymerization in water phase and spinning in sodium thiocyanate solvent to produce acrylic fiber , The comprehensive wastewater discharged from production is treated by the following methods.

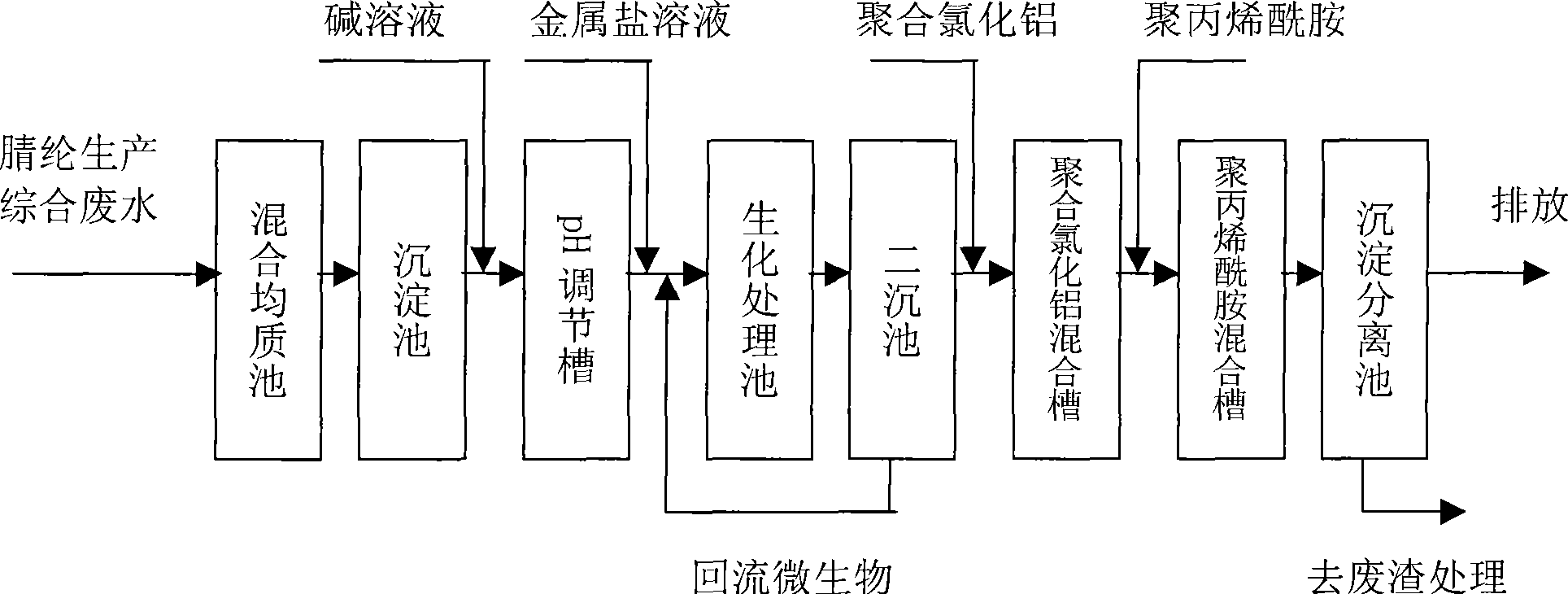

[0034] The production wastewater of each unit first enters the mixing and homogenizing tank for homogenization, and then enters the sedimentation tank to remove suspended solids. The hydraulic retention time of the mixing and homogenizing tank is 24 hours, the hydraulic retention time of the sedimentation tank is 2 hours, and the surface load is 0.2m 3 / m 2 .h; the wastewater after homogeneous precipitation enters the pH adjustment tank, and the pH of the wastewater is adjusted to 7 to 8.5 with 5% sodium hydroxide aqueous solution; the wastewater after pH adjustment is sent to the biochemical treatmen...

Embodiment 2

[0041] An acrylic fiber factory adopts the two-step wet spinning process of aqueous phase suspension polymerization and spinning in sodium thiocyanate solvent to produce acrylic fiber, and the comprehensive wastewater discharged during production is treated by the process method of Example 1.

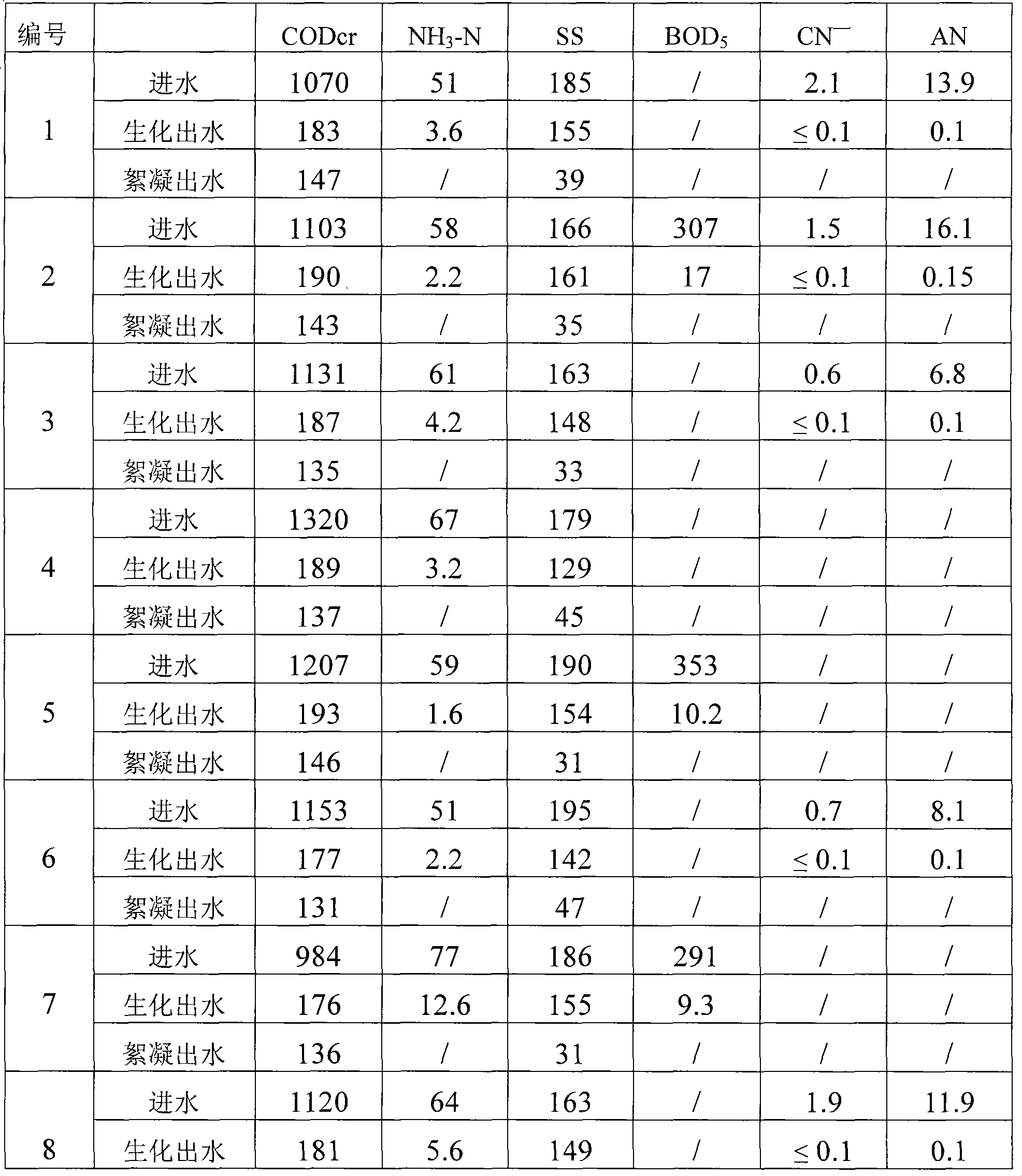

[0042] Process operation parameters In addition to the addition of polyaluminum chloride 150mg / L and polyacrylamide addition of 12mg / L in flocculation, the addition of ferric chloride, magnesium chloride and calcium chloride aqueous solution is: iron ion 120mg / L, magnesium ion 250mg / L L, calcium ion 50mg / L, the water conservancy retention time of the biochemical treatment pond is 20h, other is identical with embodiment 1. See Table 3 for the processing results.

[0043] table 3

[0044]

[0045]

[0046] The appearance of the effluent in the table is colorless and transparent, with a pH of 6-8. (The units of test items in the table are mg / L)

Embodiment 3

[0048] An acrylic fiber factory adopts the two-step dry spinning process of aqueous phase suspension polymerization and spinning in dimethylformamide (DMF) solvent to produce acrylic fiber, and the comprehensive wastewater discharged in the production is processed by the process method of Example 1.

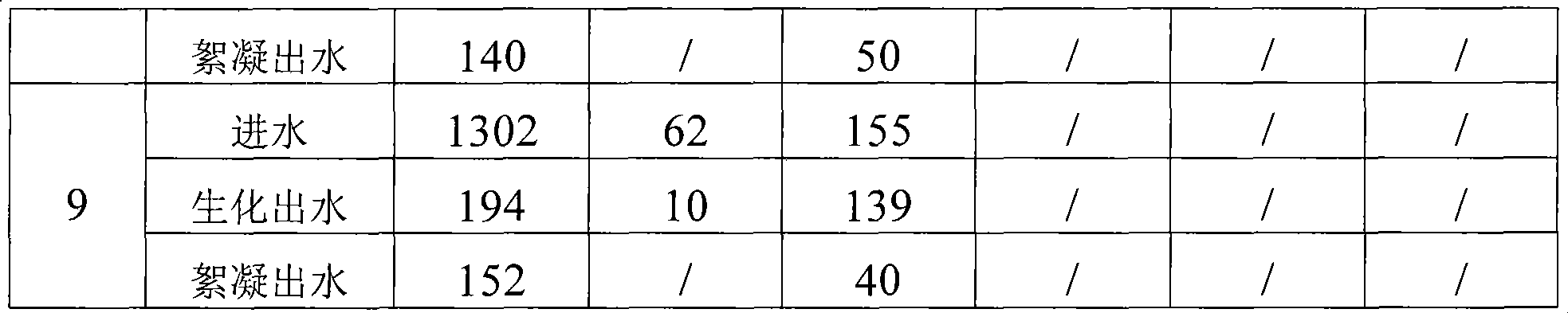

[0049] Process operation parameters In addition to adding 200mg / L of polyaluminum chloride and 15mg / L of polyacrylamide in flocculation, the addition of iron sulfate, magnesium sulfate and calcium chloride aqueous solution is: iron ion 150mg / L, magnesium ion 300mg / L L, calcium ion 60mg / L, the water conservancy retention time of the biochemical treatment pool is 24h, other is identical with embodiment 1. See Table 4 for the processing results.

[0050] Table 4

[0051]

[0052]

[0053] The appearance of the effluent in the table is colorless and transparent, with a pH of 6-8. (The units of test items in the table are mg / L)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com