Preparation device and method of first-stage reverse osmosis after chemical desalt optimization pure water

A technology of reverse osmosis device and preparation device, which is applied in the direction of osmosis/dialysis water/sewage treatment, general water supply saving, non-polluted water treatment, etc., and can solve the problems of lack of follow-up chemical desalination system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

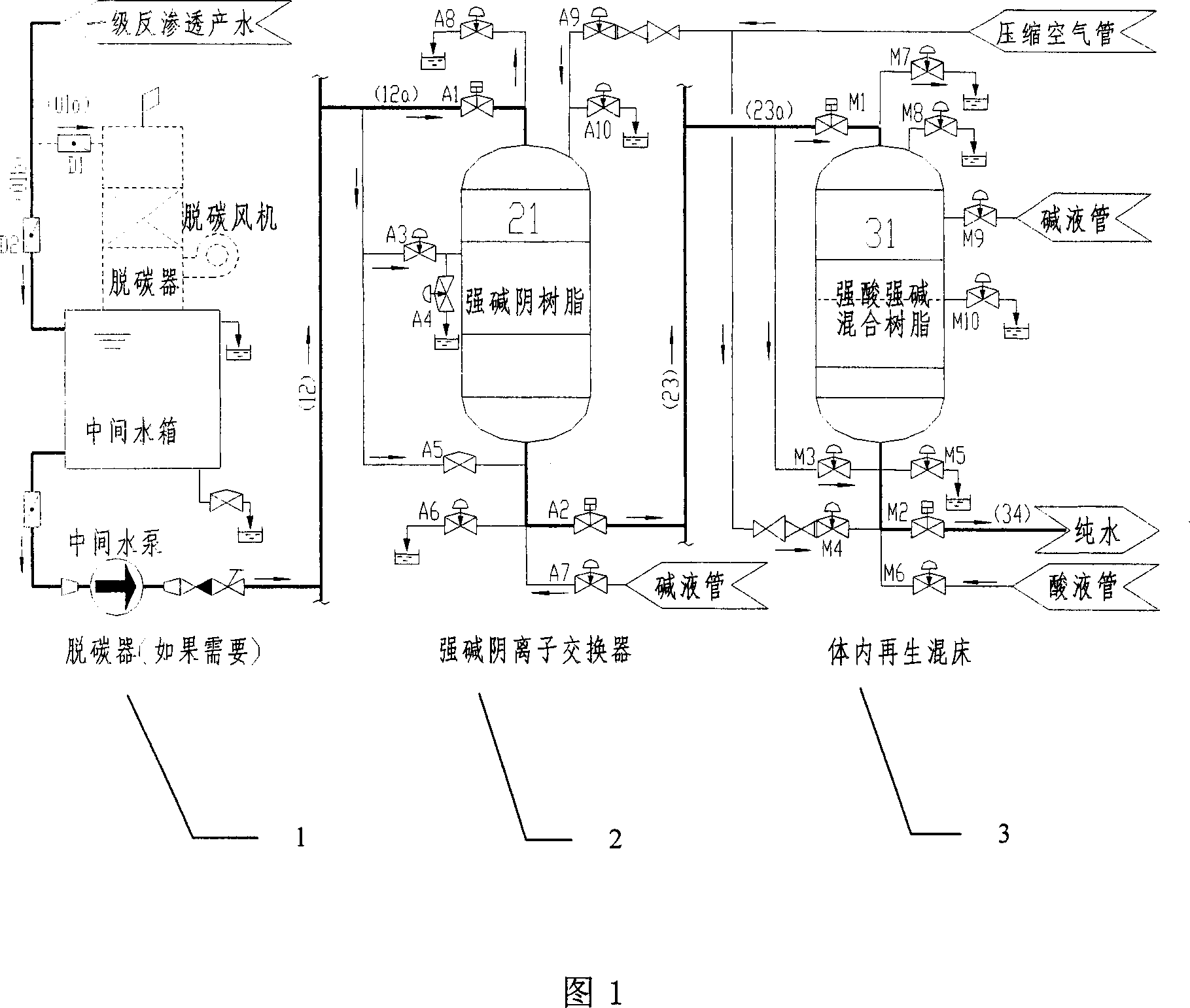

[0055] As shown in Figure 1, the first-stage reverse osmosis follow-up chemical desalination optimizes the pure water preparation device, including the water produced after the first-stage reverse osmosis unit to the decarbonizer unit 1 for removing free carbon dioxide in the water, passing through the intermediate water tank and the intermediate The water is pumped to the strong base anion exchanger unit 2 for removing residual anions in the water, and the positive and negative mixed ion exchanger unit 3 for removing residual cations and anions in the water, and finally the water is delivered to the pure water tank.

[0056] The channel 01a of the water produced by the primary reverse osmosis device is equipped with a decarburizer unit 1 for removing free carbon dioxide in the water, and whether the decarburizer is installed or not is determined according to the water quality of the produced water of the primary reverse osmosis device; if there is no decarburizer unit 1, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com