Device for restoration of persistent organic pollutant-polluted soil and use method thereof

A technology for organic pollutants and polluted soil, which is applied in the field of devices for repairing persistent organic pollutant-contaminated soil. It can solve the problems of small single-time processing capacity, high energy consumption, and increased degradation time of planetary ball mills, and achieve simple operation. Reliable, simple process flow and simple process system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

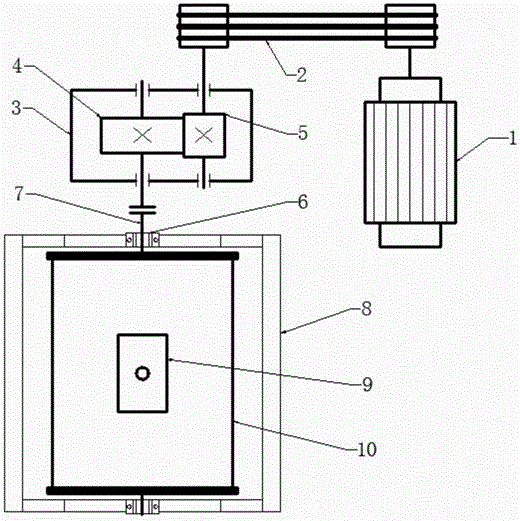

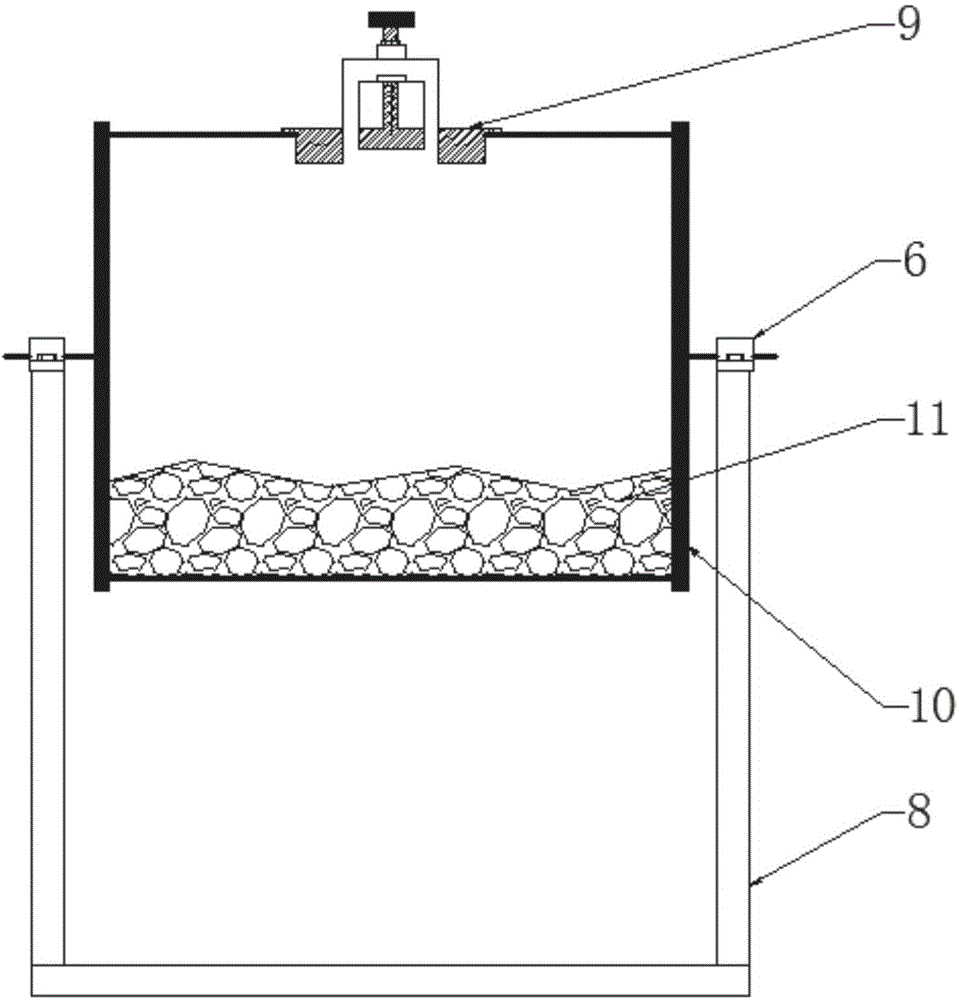

[0031] Such as figure 1 , figure 2 As shown, the device for remediating persistent organic pollutant-contaminated soil includes a belt drive 2, a transmission gear set 3, a horizontal ball milling cylinder 10, a cylinder support 8, a grinding ball 11 and a motor 1 for providing a power source. To realize large-scale remediation of POPs-contaminated soil by mechanochemical method.

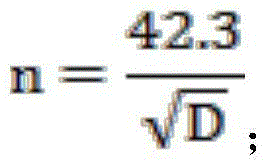

[0032] The horizontal ball milling drum 10 is a cylindrical structure with a circular cross section, and the capacity of the horizontal ball milling drum 10 is 0.1-100m 3 Among them, a horizontal ball milling drum 10 with a capacity of Φ450×550 mm is used here, which can be used to treat 5 kg of PCBs-contaminated soil. The side of the cylindrical structure is provided with a feed port cover 9. When the feed port cover 9 is opened, it is used to add or pour out con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com