Skid-mounted lightweight oily sewage treatment device and treatment technology thereof

A treatment device and treatment process technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the inconvenience of oil production station construction, packing fouling, frequent equipment cleaning, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Index of main pollutants in the treatment of tank bottom sludge sewage with strong fluidity in an oilfield

[0055] serial number

oil (mg / L)

SS(mg / L)

Median particle size (μm)

1 (standard value)

6

2

1.5

2 (incoming water quality)

2500

2000

——

3 (outlet water quality)

3

1.82

1.25

[0056] The front end of the oil sludge at the bottom of the tank has undergone fluidization treatment. It can be seen from Table 1 before entering the device of the present invention that oil is the main pollutant. The present invention mainly takes sewage with relatively high oil content in raw water as the removal target. substances were effectively removed.

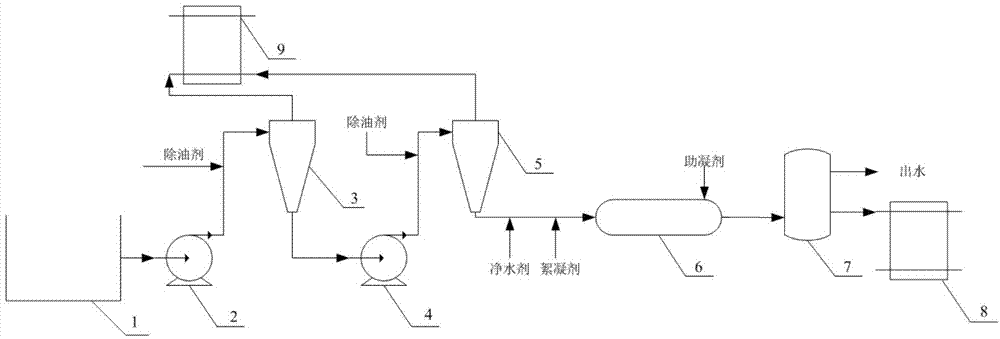

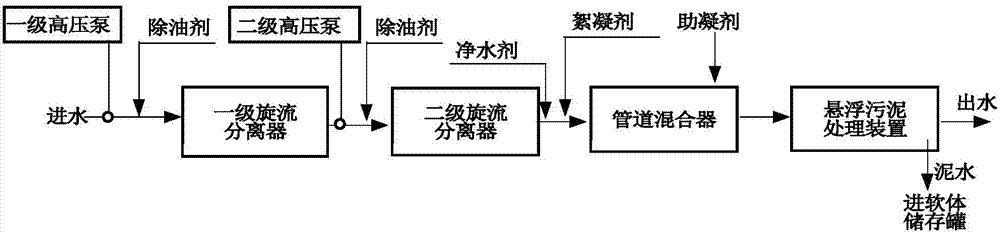

[0057] According to technological process of the present invention (as figure 2 ), the processing method and results are as follows:

[0058] (1) Coagulation treatment: The oil content in the wastewater is 2500mg / L, after the high-pressure pump 2 (e...

Embodiment 2

[0063] Main indicators of oily wastewater treatment in a heavy oil area of Liaohe Oilfield

[0064] serial number

oil (mg / L)

SS(mg / L)

Median particle size (μm)

1 (standard value)

6

2

1.5

2 (incoming water quality)

3000

1800

——

3 (outlet water quality)

2.34

1.57

1.25

[0065] With the method of the present invention, the oily sewage in the heavy oil area of Liaohe Oilfield is processed, and the processing method and results are as follows:

[0066] (1) Coagulation treatment: the oil content in the wastewater is 3000mg / L, after the high-pressure pump 2 (equipped with a frequency conversion system, the water inlet pressure is controlled at 0.4-0.8MPa), 1.5mg / L of degreaser is added, and separated in the first-stage cyclone After the hydraulic mixing in the device 3, the outlet water was sampled, the oil content in the water was 1100mg / L, the removal rate was 63%, the suspended matter was 1780...

Embodiment 3

[0071] Main indicators of oily wastewater treatment in a heavy oil area of Karamay Oilfield, Xinjiang

[0072] serial number

oil (mg / L)

SS(mg / L)

Median particle size (μm)

1 (standard value)

6

2

1.5

2 (incoming water quality)

2875

2100

——

3 (outlet water quality)

2.46

1.13

1.32

[0073] With the method of the present invention, the oily sewage in the heavy oil area of Liaohe Oilfield is processed, and the processing method and results are as follows:

[0074](1) Coagulation treatment: the oil content in the wastewater is 2875mg / L, after the high-pressure pump 2 (equipped with a frequency conversion system, the water inlet pressure is controlled at 0.4-0.8MPa), 1.25mg / L of degreaser is added, and separated in the first-stage cyclone After the hydraulic mixing in the device 3, the outlet water was sampled. The oil content in the water was 1955 mg / L, the removal rate was 68%, the suspended mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com