Synthetic method of isooctyl nitrate

A technology of isooctyl nitrate and a synthesis method, applied in the synthesis field of isooctyl nitrate, can solve problems such as low product yield, low production efficiency, high safety hazard, etc., and achieves high finished product yield, low production cost, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

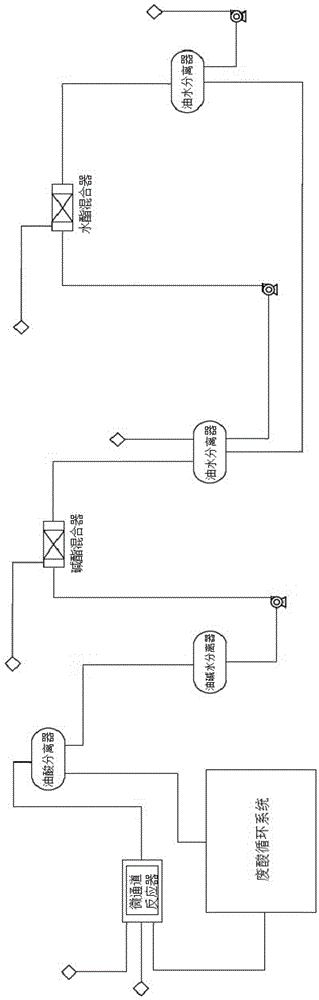

[0023] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0024] Such as figure 1 Shown, the invention provides a kind of synthetic method of isooctyl nitrate, comprises the following steps:

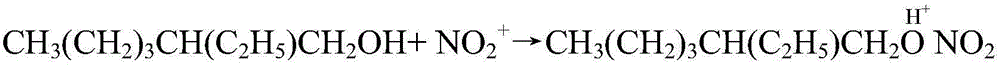

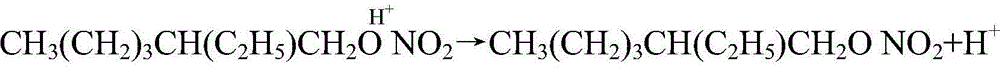

[0025] a) Prepare a mixed acid solution, mix a concentrated sulfuric acid solution with a mass ratio of 90% and a concentrated nitric acid solution with a mass ratio of 98% to form a mixed acid solution, the molar ratio of sulfuric acid and nitric acid in the mixed acid solution is 2:1, and set aside ;

[0026] b) the mass ratio is 99.5% iso-octanol solution and mixed acid solution are transported into the microchannel reactor from two different inlets respectively as raw material liquid, by regulating the volume flow ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com