Down-hole gross coal dirt-discharging and mine water treating combined process

A technology of mine water and coal drainage, applied in the direction of boreholes/well components, mining equipment, mining fluids, etc., can solve the complex and changeable working environment that cannot adapt to the underground water tank, damage to mechanical equipment, and blockage of coal flow lines Production and other issues, to achieve the effect of reducing invalid transportation volume, increasing production capacity, and preventing ground subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

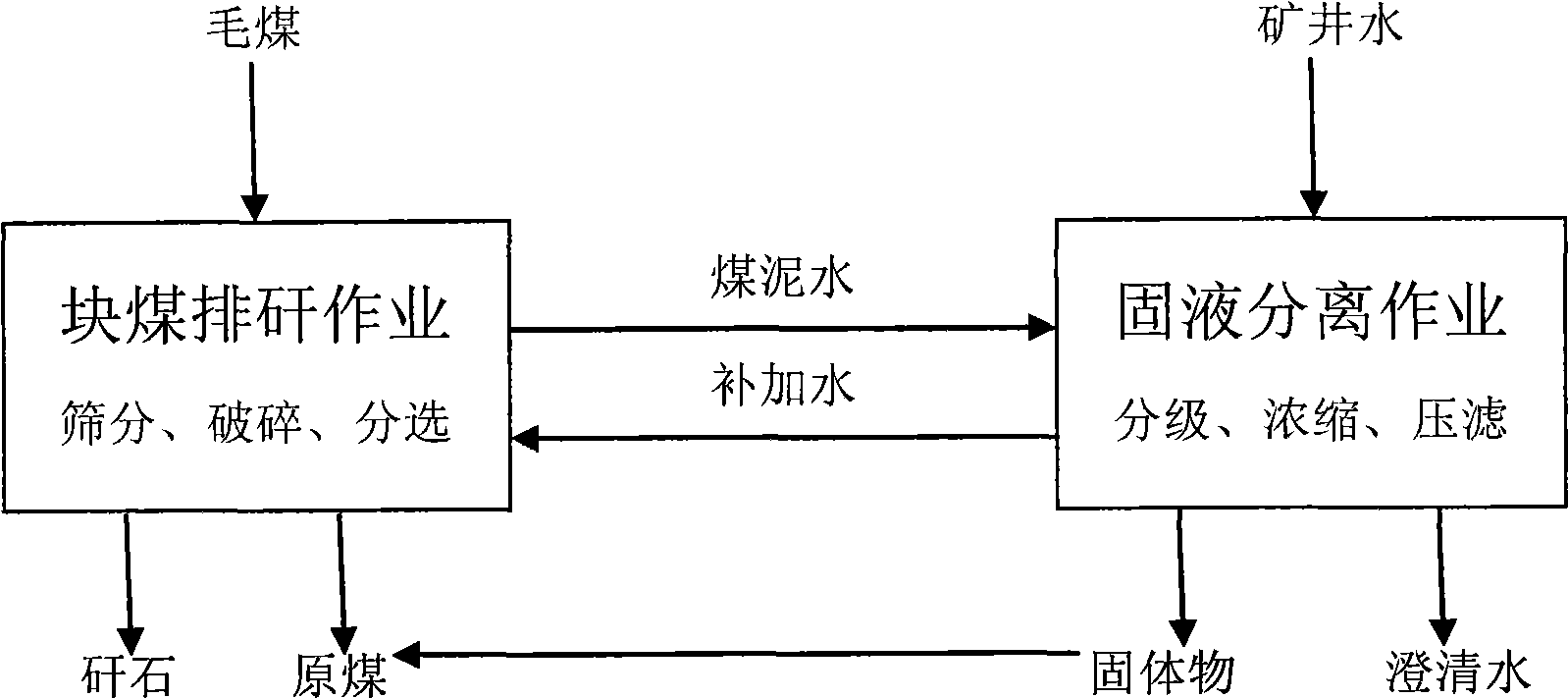

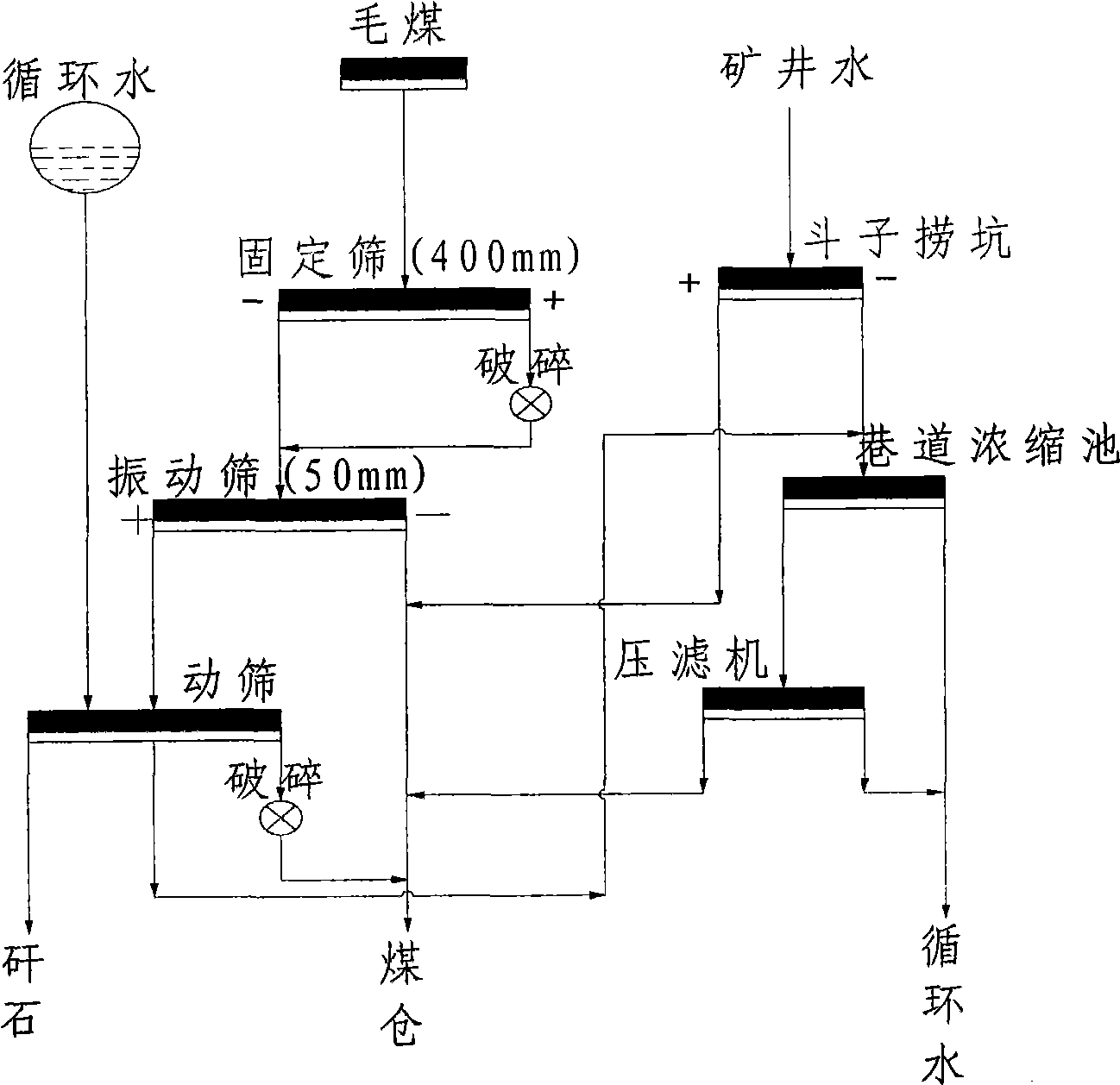

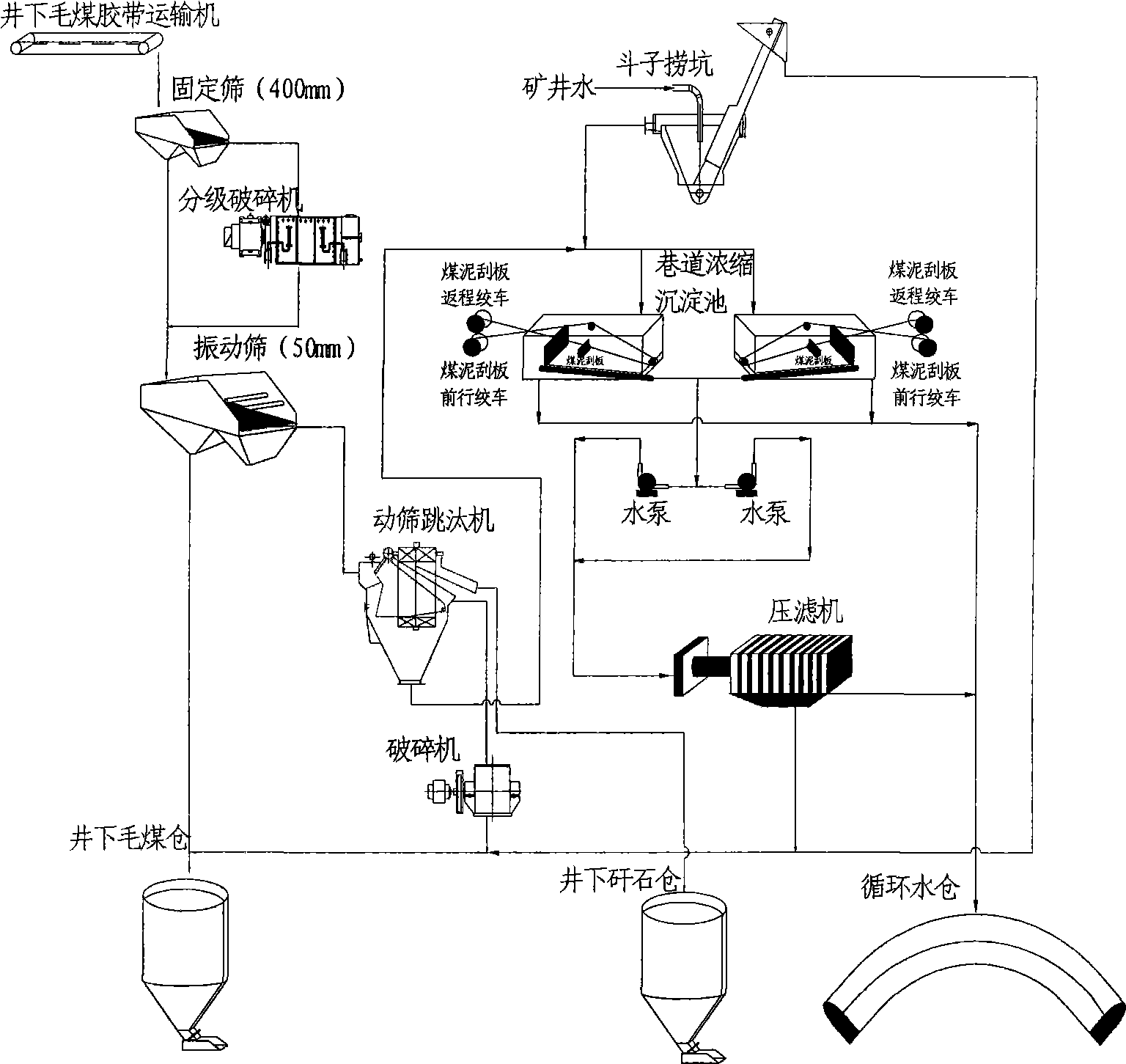

[0041] Such as figure 1 As shown, the technique of the present invention mainly includes two parts of lump coal discharge and mine water solid-liquid separation operation; wherein the lump coal discharge operation includes screening, crushing and sorting steps; and mine water solid-liquid separation operation includes hydraulic classification, Concentration and filter press steps; remove the large pieces of gangue in the raw coal through the lump coal discharge operation, and at the same time crush the large particles in it to a suitable particle size; through the solid-liquid separation of mine water, the solid in the mine water It is recycled to the coal flow line, and at the same time, the clear overflow water is sent to the underground water tank; the coal slime water generated in the lump coal discharge operation is sent to the mine water solid-liquid sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com