SCR (Selective Catalytic Reduction) denitration method and device with urea pyrolysis pipes in boiler

A urea and pyrolysis technology, applied in the field of boiler SCR denitrification, can solve the problems of high energy consumption and high operating cost of urea pyrolysis, and achieve the effects of reducing investment cost, saving operating cost, reducing energy consumption and plant power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following non-limiting examples illustrate the invention.

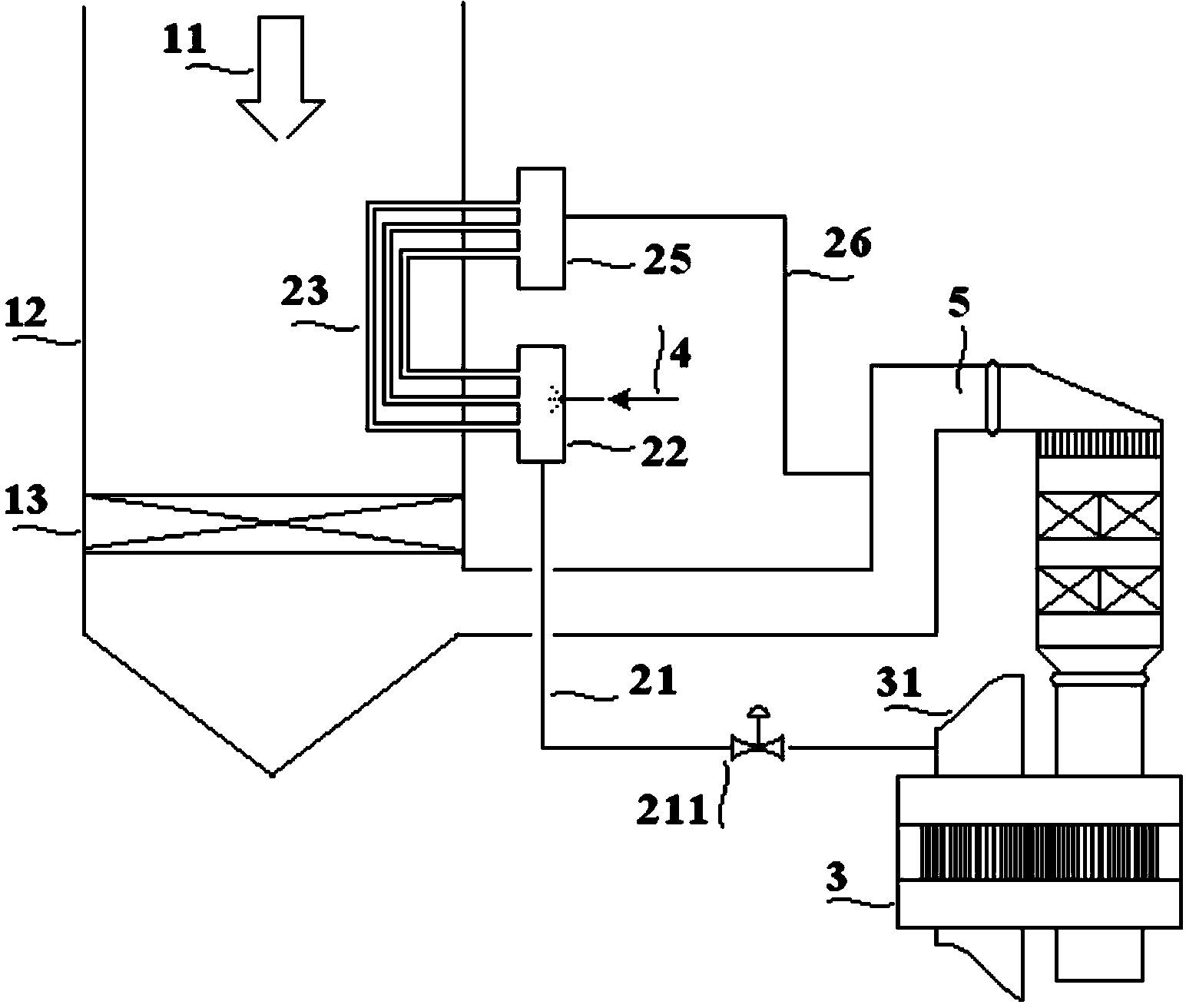

[0028] refer to figure 1 As shown, the urea pyrolysis tube bundle 23 is arranged inside the boiler so that the urea solution can be pyrolyzed into NH-containing 3 The mixed gas area of the boiler, such as the 400-800°C area of the boiler, can specifically be the flue gas area 12 upstream of the economizer 13, and the suitable layout area is the low-temperature superheater or low-temperature reheater area.

[0029] The urea pyrolysis air supply pipe 21 leads the primary air 31 (pressure 10±2kPa) of the air preheater 3, and enters the urea pyrolysis tube bundle 23 through the urea pyrolysis tube bundle inlet distribution pipe 22. The leading primary air can be hot primary air or cold primary air, and a fan can also be configured separately to provide air.

[0030] The urea solution 4 with a mass concentration of about 50% supplied by the urea solution supply device is sprayed into the inlet distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com