Tubular oil-water cyclone separation equipment

A technology of cyclone separation and oil-water separation, which is applied in the oil-water separation process and the field of tubular oil-water cyclone separation equipment, which can solve the problems of increasing monomer processing capacity and achieve the effects of reducing investment and operating costs, high performance and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0014] The preferred embodiment of the tubular oil-water cyclone separation device of the present invention is:

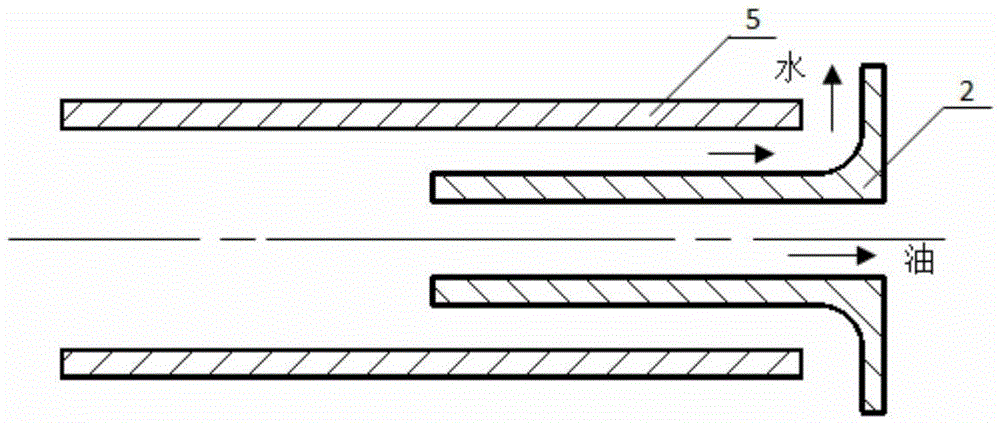

[0015] It includes a liquid inlet pipe, a spinner, a separation chamber and a liquid discharge pipe. The liquid discharge pipe includes an oil discharge pipe and a drain pipe. The liquid inlet pipe, the spinner, a separation chamber and a drain pipe are sequentially connected by flanges or welding .

[0016] The liquid inlet pipe, the spinner, the separation chamber and the drain pipe are sequentially connected to form a tubular structure as a whole, the liquid inlet pipe is connected to the liquid incoming pipe through a flange, and the drain pipe is connected to a downstream pipeline through a flange.

[0017] The spinner includes a blade carrier, a guide vane and an outer tube, and the guide vane is closely matched with the blade carrier and the outer tube in the radial direction.

[0018] The guide vane includes a drainage section, a swirling section and a flo...

specific Embodiment

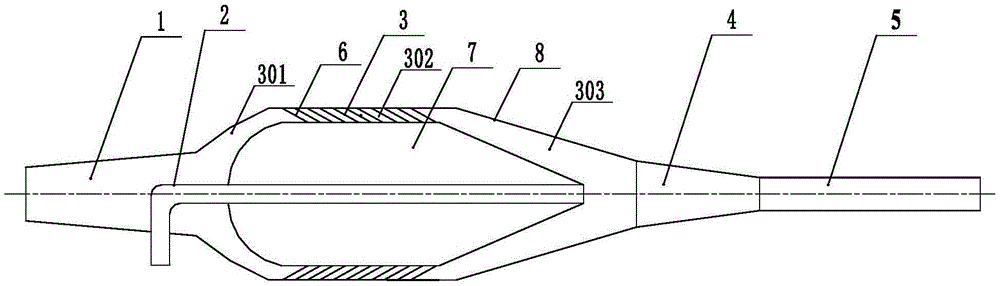

[0026] Such as figure 1 As shown, the embodiment of the present invention provides a pipe-type pipe-type oil-water cyclone separation device, which is composed of a liquid inlet pipe 1 , a spinner 3 , a separation chamber 4 , a drain pipe 5 and an oil discharge pipe 2 .

[0027] Wherein, the liquid inlet pipe 1, the spinner 3, the separation chamber 4 and the drain pipe 5 can be connected sequentially by flanges or welding, and each part is in a tubular structure as a whole after being connected.

[0028] The liquid inlet pipe 1 and the drain pipe 5 are provided with flanges connected with external equipment, and can be connected with upstream and downstream equipment or pipelines respectively.

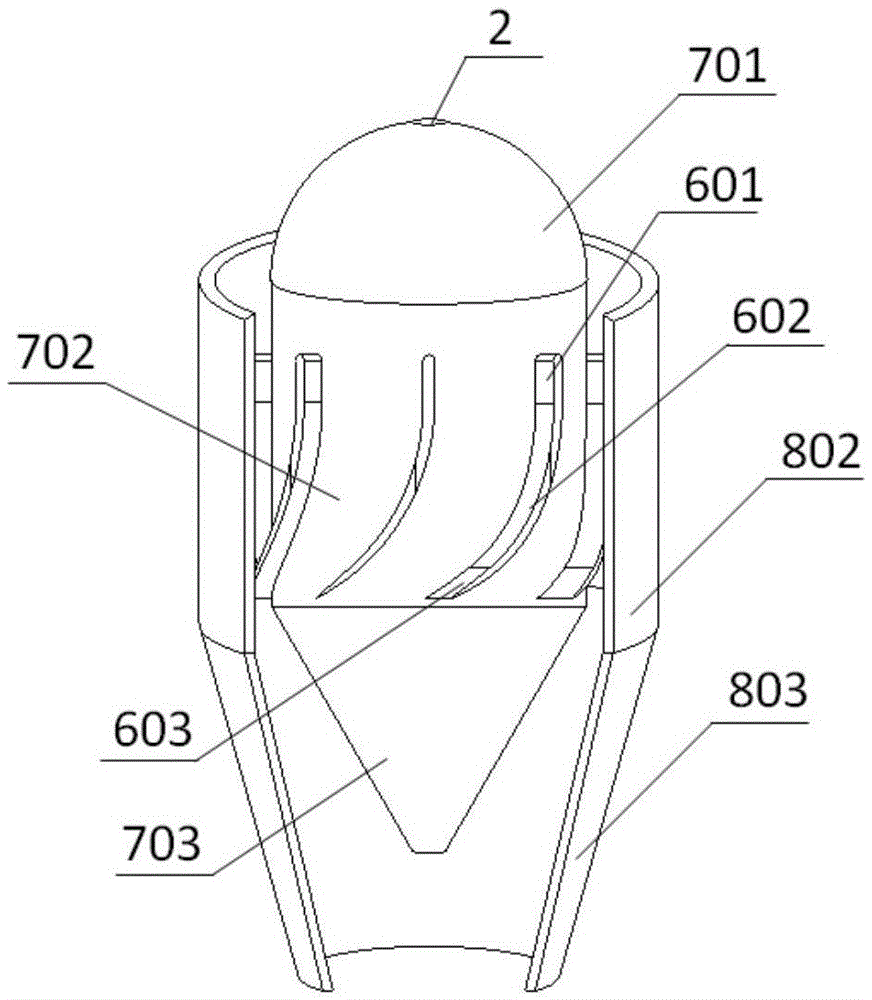

[0029] Such as figure 2 As shown, the above-mentioned spinner 3 is composed of a guide vane 6, a blade carrier 7 and an outer tube 8 of the spinner; the guide vane 6 is an interference fit with the blade carrier 7 and the outer tube 8 of the spinner.

[0030] Such as figure 2 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com