Method and equipment for separating diolefin component in oil cracking ethylene byproduct carbon-5 fraction

A technology of by-product C5 fraction and C5 fraction, applied in distillation purification/separation, addition of unsaturated hydrocarbons to hydrocarbons, organic chemistry, etc., can solve the problems of complicated separation methods and poor separation effects, and achieve broaden Application range, easy reaction and stable control, enhanced heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

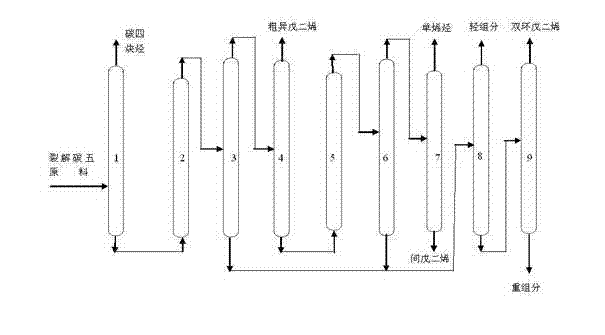

[0057] Such as Figure 5 As shown, the cracked C5 fraction enters the light removal tower 1, and the light components containing carbon four hydrocarbons are removed through the top of the light removal tower 1, and the material separated from the light removal tower enters the first-stage reactor, and the reaction temperature is 85- Thermal dimerization reaction is carried out at 100°C and the reaction pressure is 0.75-0.90MPa, so that the cyclopentadiene in the material is dimerized into dicyclopentadiene, and then the material enters the first de-weighting tower, and is separated at the top of the tower to obtain isoprene-rich and the material of piperylene, the tower still is separated to obtain the material rich in dicyclopentadiene. The material separated at the top of the first weight removal tower enters the deisoprene tower after being cooled, and the crude isoprene product separated at the top of the tower leaves the factory, and is separated at the bottom of the tow...

Embodiment 2

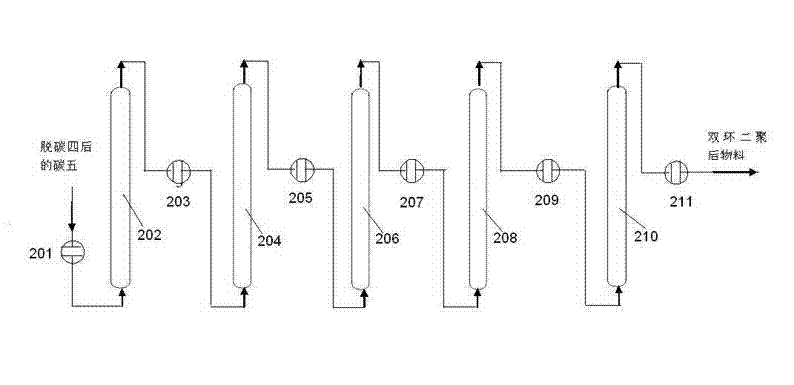

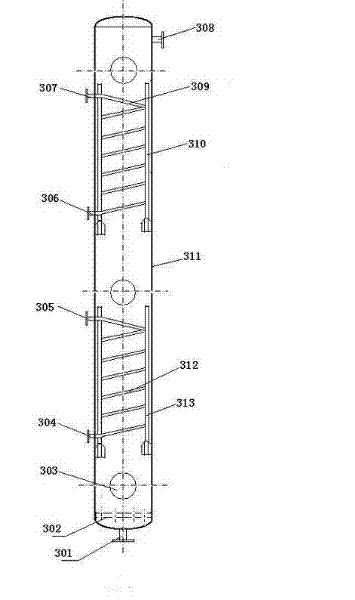

[0067] The equipment and method used in this embodiment are basically the same as in Example 1, the difference is that a dicyclopentadiene de-weighting tower is also provided after the dicyclopentadiene removal tower, and the tower still material of the dicyclopentadiene removal tower enters the double ring Deweighting is carried out in the pentadiene deweighting tower, the dicyclopentadiene product is obtained by separation at the top of the tower, and the heavy component is separated from the bottom of the tower. The theoretical plate number of the dicyclopentadiene weight removal tower is 40, the temperature at the top of the tower is 97°C, the temperature at the bottom of the tower is 120°C, the pressure inside the tower is controlled between -0.08 and -0.09MPa, and the reflux ratio is 5. In addition, the first-stage reactor in this embodiment is provided with three thermal dimerization reactors connected in series, and each thermal dimerization reactor is equipped with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com