Old asphalt concrete regenerant and preparation method thereof

A technology of concrete regeneration and old asphalt, which is applied in the direction of building components, building insulation materials, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

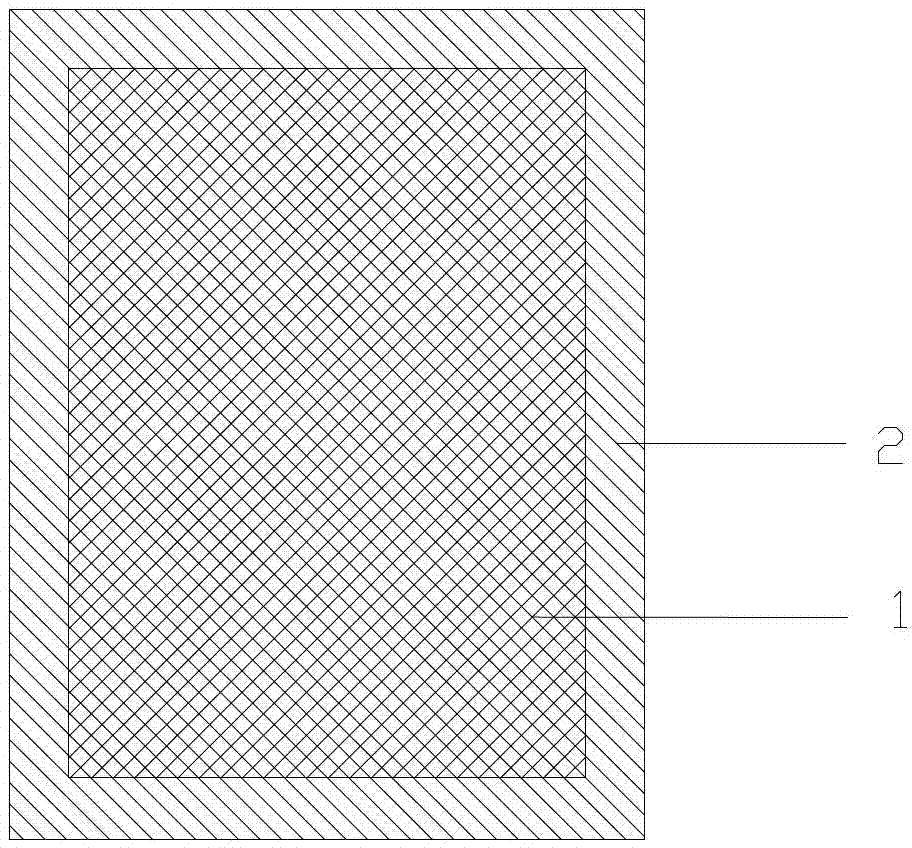

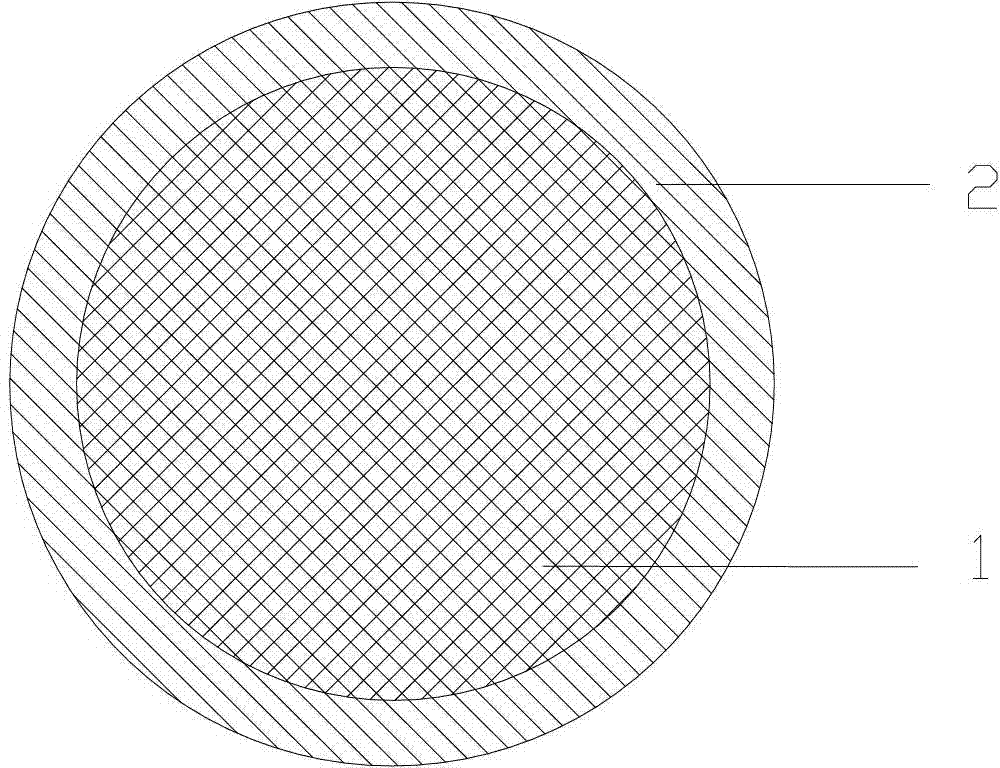

Image

Examples

preparation example Construction

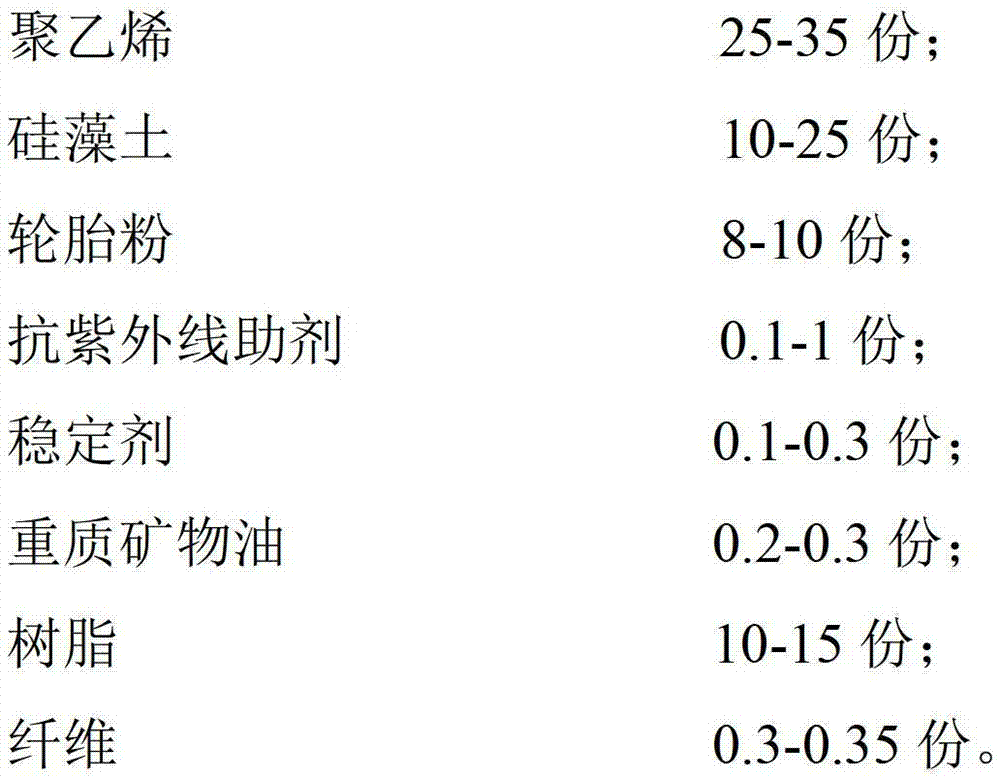

[0032] The present invention also specifically provides a preparation method for the above-mentioned old asphalt concrete rejuvenator, including:

[0033] In one mixing step, add anti-ultraviolet additives, diatomaceous earth, stabilizer, heavy mineral oil, resin, and fiber into the horizontal color mixing machine in the silo device to uniformly mix to form a semi-finished material;

[0034] In the secondary mixing step, put the semi-finished material into a horizontal color mixer, add PE and tire powder and mix again, and then use a twin-screw extruder to produce the old asphalt concrete regeneration agent.

[0035] In the preparation method according to the present invention, the temperature of the primary mixing step is room temperature, and the mixing time is 5 to 10 minutes; the mixing temperature in the secondary mixing step is room temperature, and the mixing time is 30 to 50 minutes ; The production temperature of the twin-screw extruder is 140°C to 165°C.

[0036] In...

Embodiment 1

[0040] In one mixing step, add anti-ultraviolet additives, diatomaceous earth, stabilizer, heavy mineral oil, resin, and fiber into the horizontal color mixing machine of the silo device to uniformly stir to form a semi-finished material; the temperature is room temperature, and the mixing time is 5 ~10 minutes;

[0041]Secondary mixing step, put the semi-finished material into a horizontal color mixer, add PE and tire powder and mix again, and then use a twin-screw extruder to produce the old asphalt concrete regeneration agent; the mixing temperature is room temperature, and the time is 30-50 minutes; the production temperature of the twin-screw extruder is 140°C to 165°C.

Embodiment 2

[0043] Put all the materials together into a horizontal color mixing machine at one time and mix them evenly to form a semi-finished material. Stir for 40-60 minutes at room temperature, then put the semi-finished material after mixing into the hopper of a twin-screw extruder equipped with a matching mixer. Stir evenly for 10-15 minutes, and then extrude the old asphalt concrete regeneration agent by twin-screw extruder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com