Smarter-vision-based high-performance ore granularity visual inspection system

A technology of intelligent vision and visual inspection, which is applied in the field of intelligent vision, can solve the problems that the crusher is not connected to form a closed-loop control, the accuracy of the ore particle size detection equipment is not high, and the quantity information of the ore cannot be given at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

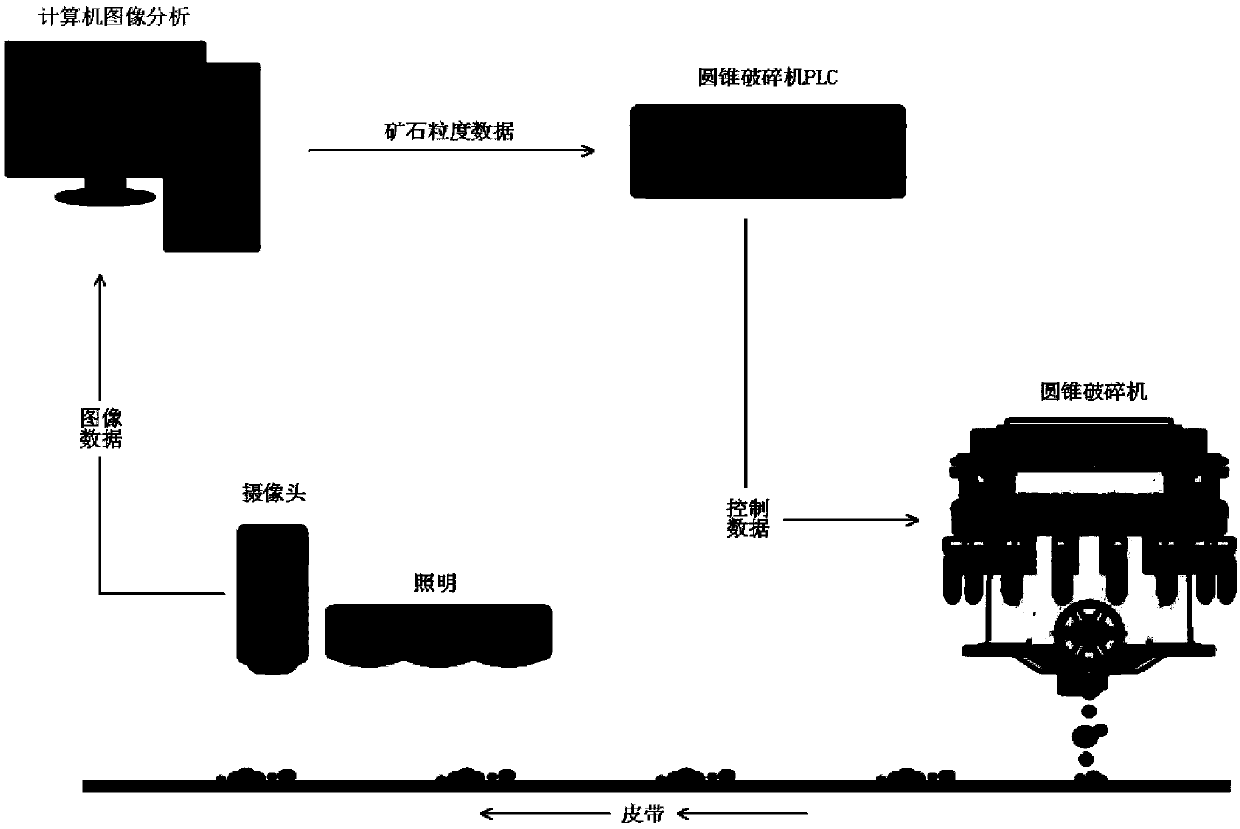

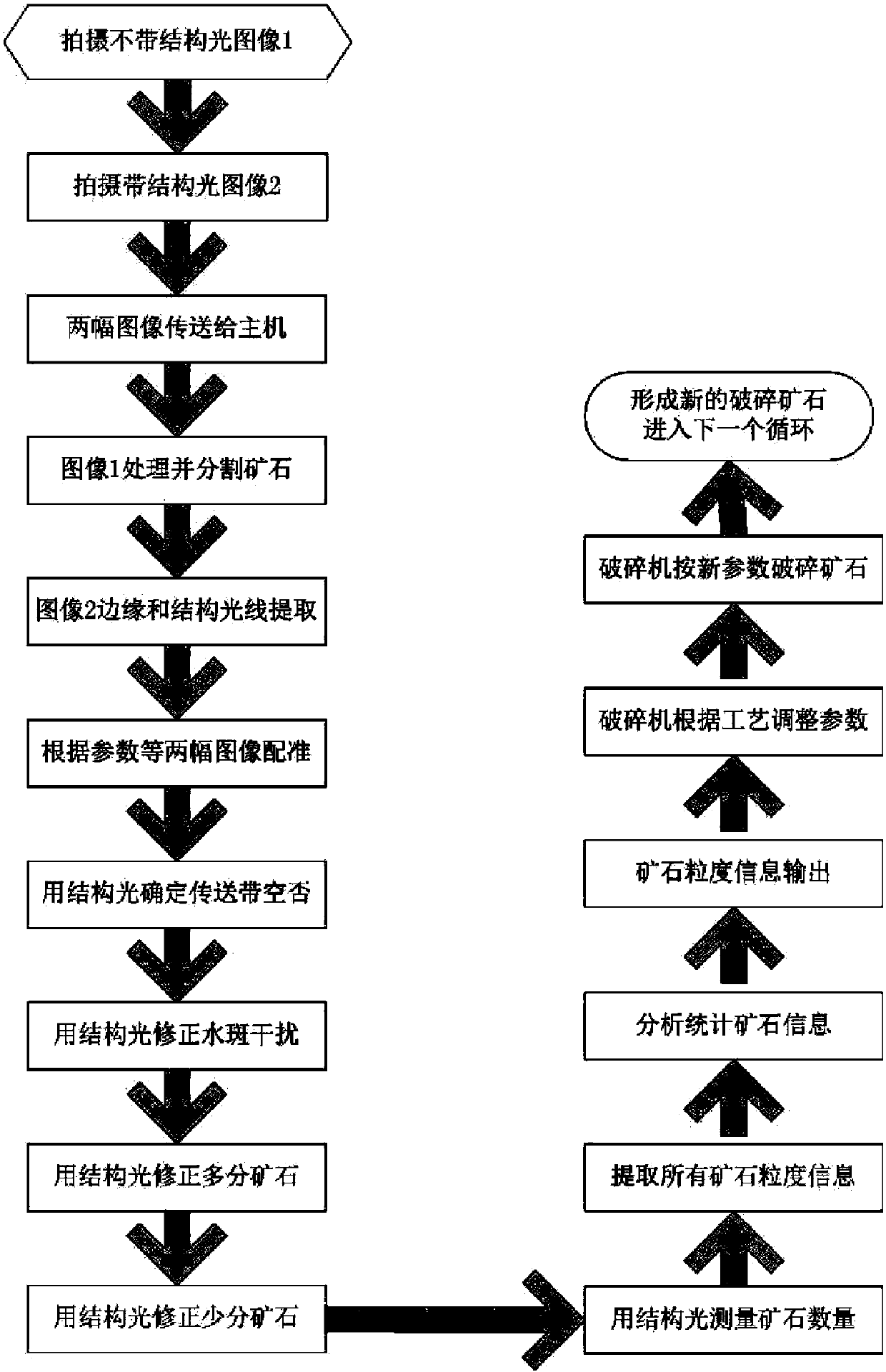

[0062] Such as figure 1 As shown, a kind of high-performance ore particle size visual detection system based on intelligent vision of the present invention realizes ore particle size visual detection by the following steps:

[0063] 1) Install a high-speed, high-definition camera above the ore conveyor belt;

[0064] 2) Take two images of the broken ore on the conveyor belt through the camera, the first one is a normal image, and the second one is an image with structured light;

[0065] 3) Transfer the above two image information to the system host for detection, segment ore particles and extract ore particle size information for statistics and analysis, and output to the main controller of the ore crusher;

[0066] 4) The main controller of the ore crusher adjusts various control parameters of the ore crusher according to the production process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com