Corn starch pasting method

A technology of corn starch and starch, which is applied in the field of corn starch gelatinization, can solve the problems of high energy consumption, low utilization rate, and poor inhibition effect, and achieve the effects of good selectivity, improved utilization rate, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] 1. Weighing

[0029] According to cornstarch, caustic soda mass ratio is the ratio of 3-5: 1 to take raw material,

[0030] Two, lye making

[0031] Prepare caustic soda into 5-10% aqueous solution,

[0032] 3. Preparation of corn starch suspension

[0033] Prepare cornstarch into 5-10% suspension,

[0034] 4. Causticization

[0035] Add the caustic soda solution into the cornstarch suspension, stir while adding, and let it stand for 30-10 minutes to obtain causticized starch colloid, which is diluted to the required concentration when used.

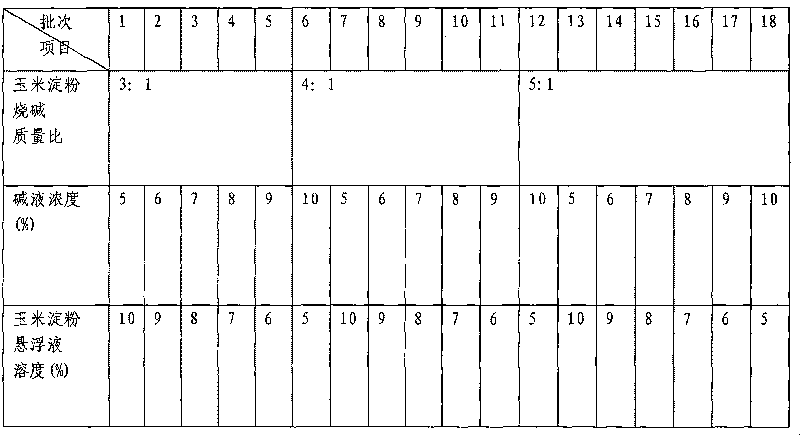

[0036] The ratio of raw materials for each batch of causticized starch colloid is prepared, and the concentration is detailed in the table below

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com