Technology for flotation of lead and zinc sulfide ores through inflatable floatation columns

A flotation column, inflatable technology, used in flotation, solid separation, etc., to achieve the effect of simplifying the process, uniform feeding, and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

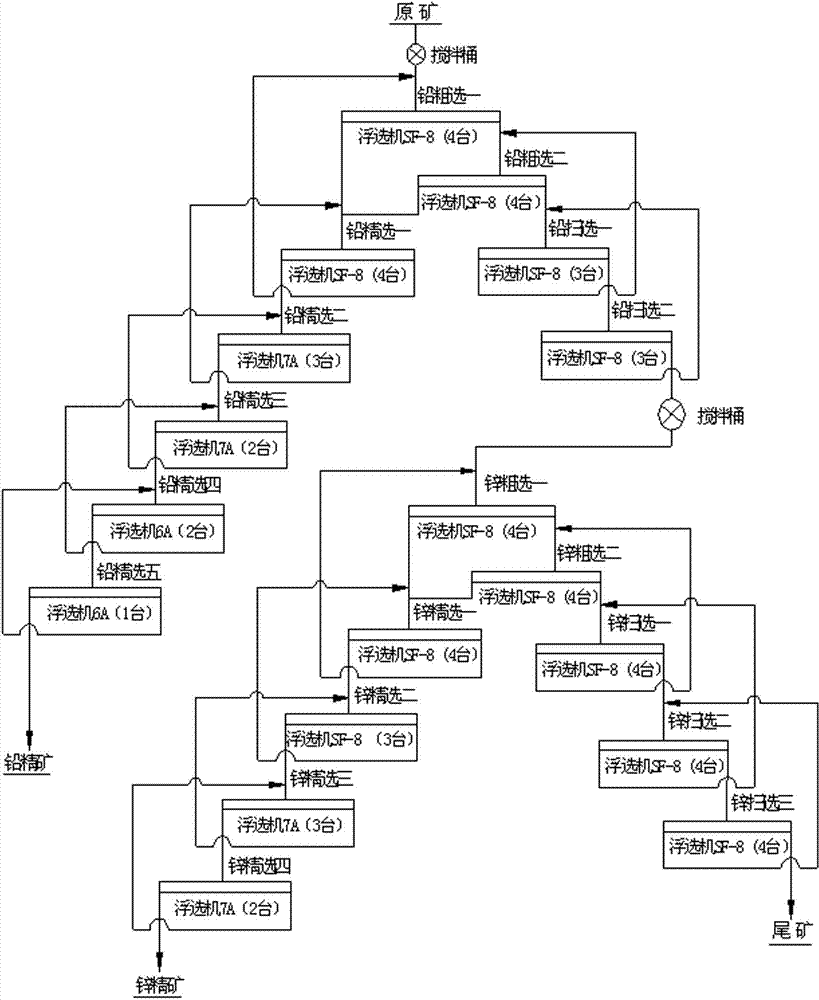

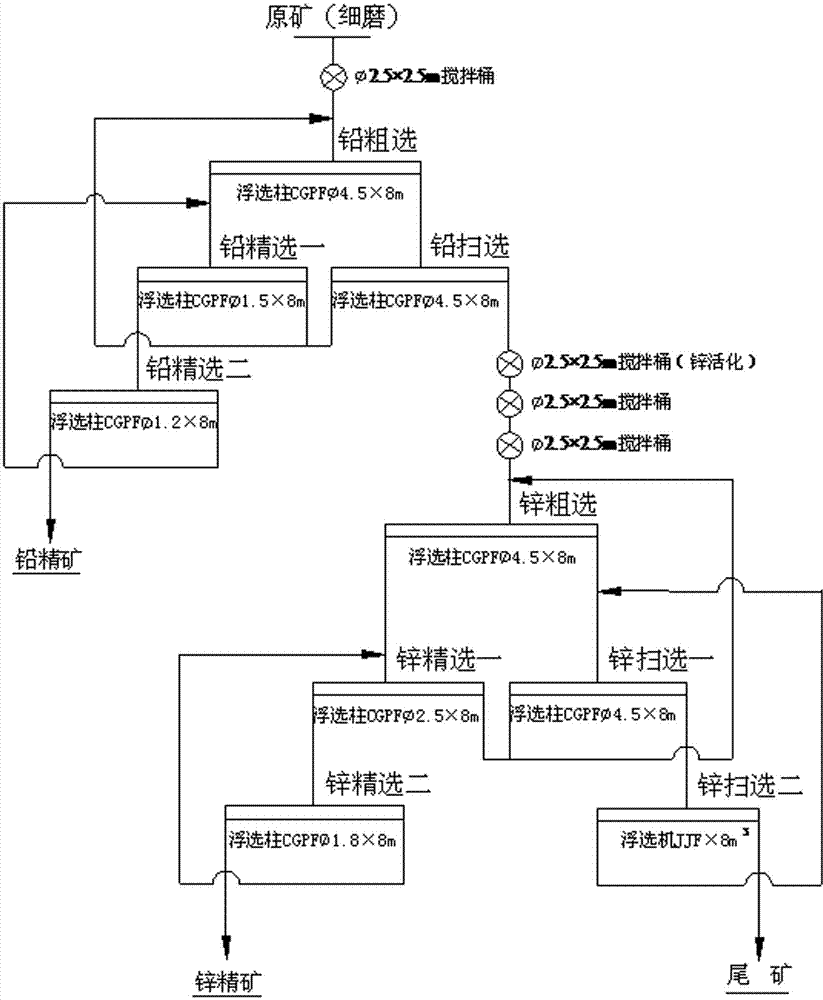

Image

Examples

Embodiment approach

[0084] (1) Basic work research——research on ore properties, technological process and technological parameters, and characteristics of flotation column equipment. The research shows that the grinding fineness of the selected raw ore, the foaming effect of the flotation column, and the beneficiation efficiency are the keys to the quality of the flotation index;

[0085] (2) Use small-scale flotation column test device to carry out small-scale experimental research in the laboratory;

[0086] (3) Partial industrial tests were carried out with industrial equipment to provide a reliable basis for industrial production; industrial tests were carried out for flotation of low-grade, complex, and refractory lead-zinc sulfide ores with inflatable flotation columns, and the use of flotation columns was demonstrated. The feasibility of carrying out flotation of lead-zinc ore and mastering the shortcomings of the process provide a design basis for industrial application.

Embodiment 1

[0087] Embodiment 1: Through the industrial test of lead roughing by flotation column, a reasonable grinding fineness is determined. According to the test, when the raw ore grinding fineness reaches -200 mesh, accounting for 75.4%, the recovery rate of lead roughing single machine reaches 73.2%, and when the grinding fineness urgently needs to be increased, the recovery rate does not increase significantly. If other parameters remain unchanged, when the proportion of -200 mesh is less than 75%, the recovery rate is lower than 65.7%, and the reduction is relatively large, which directly affects the recovery rate of ore dressing. Considering the beneficiation index and the grinding cost comprehensively, the ore flotation column flotation selection grinding fineness is controlled at 75%~80%;

Embodiment 2

[0088] Embodiment 2: Through the industrial test of the flotation column, it is determined that the flotation column is applied to the roughing operation of lead-zinc ore. According to the test, the best conditions for the roughing operation of the flotation column are: the air pressure of the spray gun is 0.48 Mpa, and the gas volume per unit column section is 0.96m 3 / min, the foam layer height is 110mm. The lead roughing operation uses 2# oil as the foaming agent, lime as the regulator, butyl xanthate and ethionyl as the collector, the recovery rate of the lead roughing single machine reaches 72.6%, and the grade is 17.8%. Copper sulfate is used as the activator in zinc roughing operation, 2# oil is used as foaming agent, lime is used as regulator, and butyl xanthate is used as collector. The recovery rate of zinc roughing single machine reaches 92.8%, and the grade is 21.5%. If the air pressure, gas volume or foam layer height of the flotation column change more than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com