Rutile ore part size fraction benefication joint production process

A rutile ore and combined production technology, applied in flotation, magnetic separation, solid separation, etc., can solve the problems of difficult separation by gravity separation method, small density difference between rutile and garnet, etc., and achieve the effect of low beneficiation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

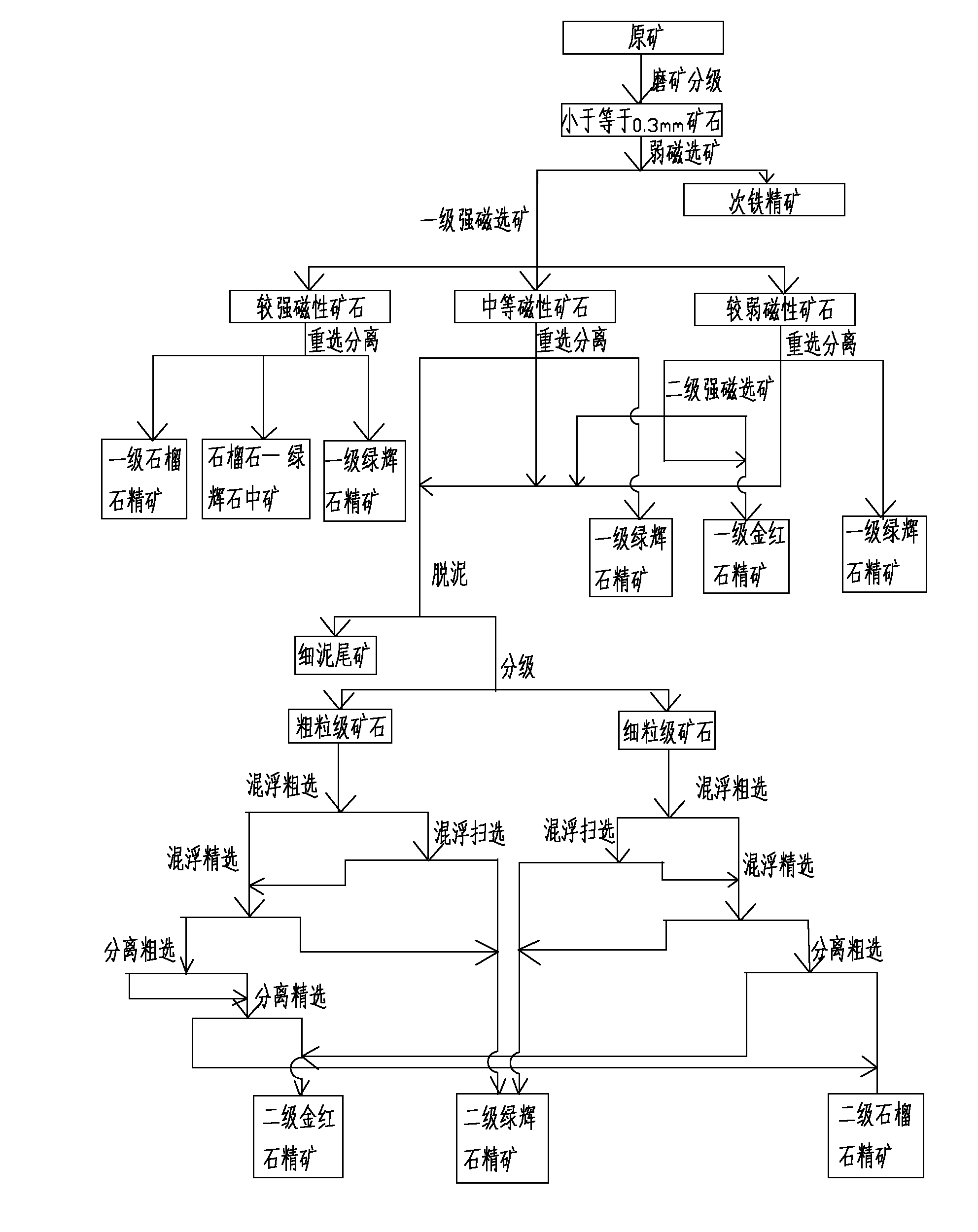

[0057] see figure 1 , the combined production process of rutile ore in the present invention is partly graded ore dressing, comprising the following steps:

[0058] a. Grinding and classification

[0059] Grind the rutile raw ore with a 200×240XMB-67 rod mill, and sieve it with a 0.3mm sieve to obtain ore with a particle size of ≤0.3mm; in the grinding and grading products, the content of 200 mesh is 27.55%, and the upper limit of the particle size is 0.3mm .

[0060] b. Weak magnetic separation

[0061] Use XCRS-74 type Φ400×300 drum-shaped wet weak magnetic separator (separation magnetic field is 1450Oe) to carry out weak magnetic ore separation on the ore with a particle size of ≤0.3mm obtained in step a to separate the secondary iron concentrate, and the rest of the ore enters the next step. step;

[0062] c. Primary strong magnetic ...

PUM

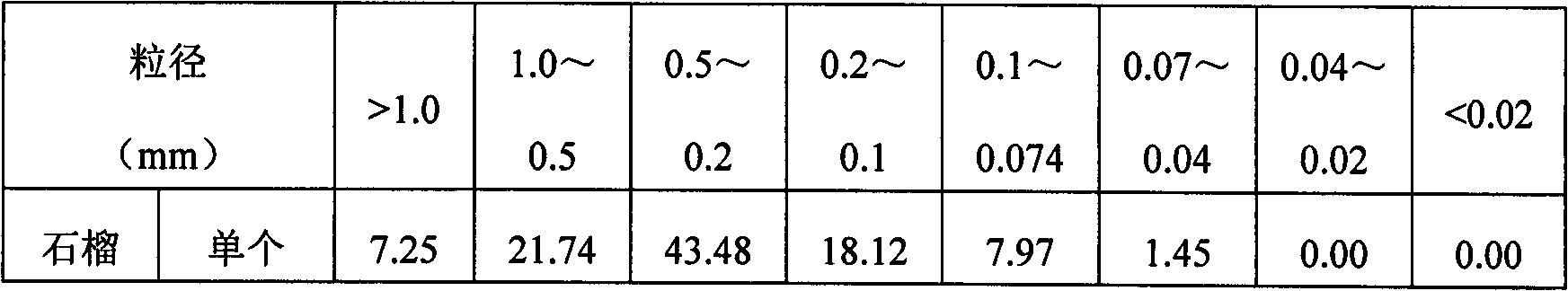

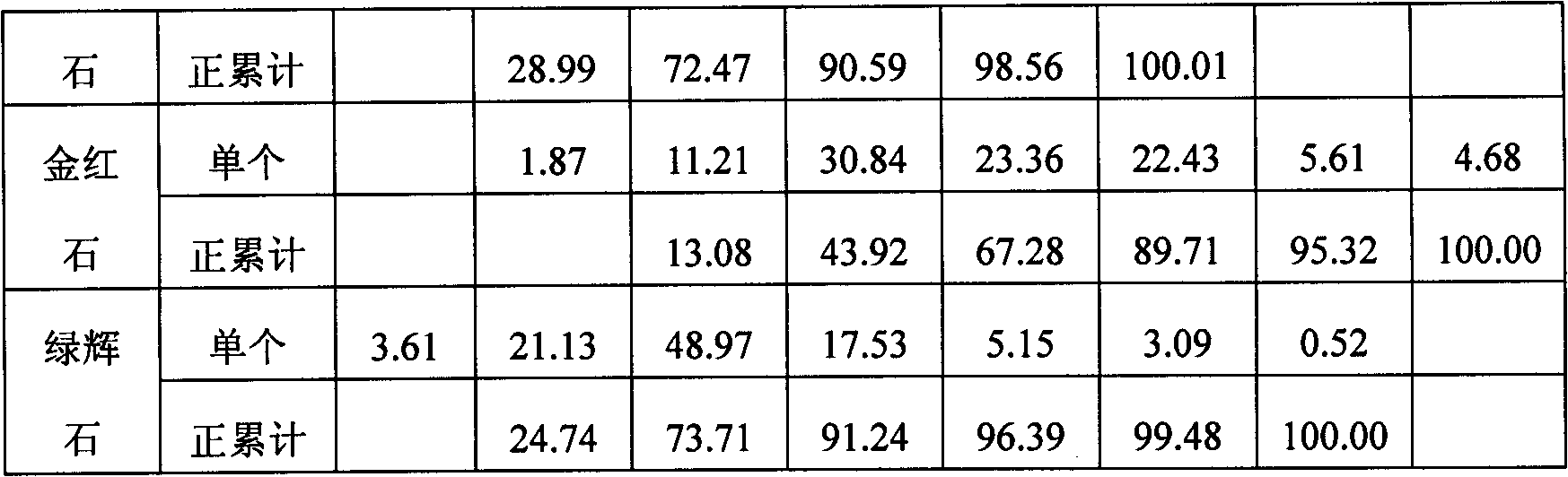

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com