Novel mineral separation process for gravity separation of useful minerals such as magnetite, apatite, ilmenite and sulfide minerals and product

A technology for useful minerals and apatite, which is applied in the field of new mineral processing technology and products obtained by implementing the technology, can solve the problems of high cost and insufficient use of technological advantages in iron separation, achieve high work efficiency and improve comprehensive utilization of resources. rate, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

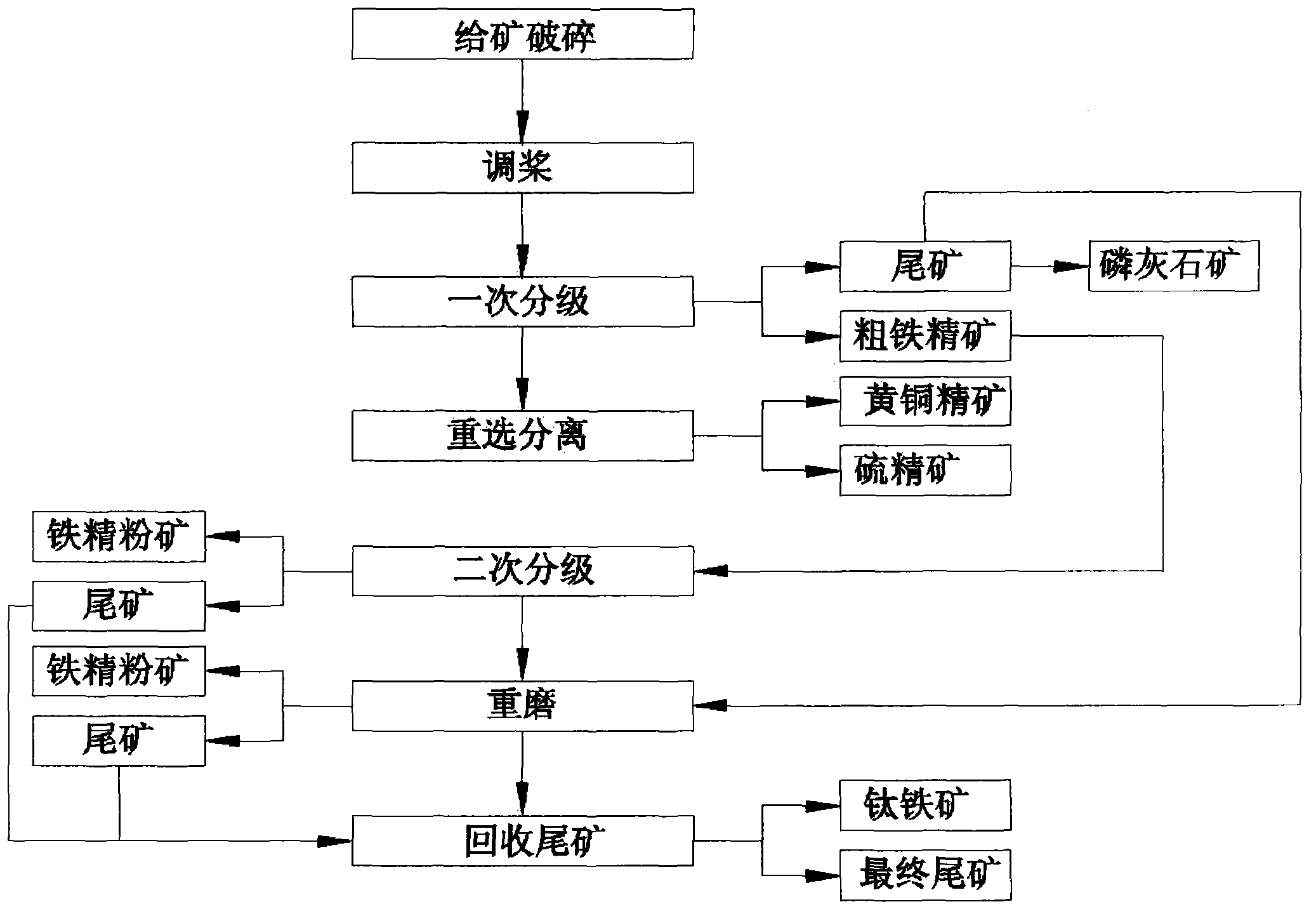

[0030] Example: see figure 1 , the present embodiment provides a novel mineral processing process for re-selecting useful minerals such as magnetite, apatite, ilmenite, sulfide ore, which comprises the following steps:

[0031] (1) Ore feeding and crushing: prepare minerals, add the minerals to crushing equipment for extrusion crushing process, and obtain powder;

[0032] (2) paddle adjustment: the powder is adjusted into a slurry to obtain a slurry;

[0033] (3) Primary classification: Classify the slurry according to the required fineness requirements for the production of apatite, and move the coarse minerals in the slurry that do not meet the fineness requirements to the mill for grinding until they meet the fineness requirements At the same time, the slurry that meets the fineness requirements is magnetically separated to obtain coarse iron concentrate and output tailings, and the magnetic separation tailings are recycled to flotation to recover apatite concentrate. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com