Preparation method for high-strength high-permeability concrete

A permeable concrete, high-strength technology, applied in the field of road paving materials, can solve problems such as not fundamentally solving problems, and achieve the effects of excellent mechanical properties and water permeability, high mechanical properties, and increasing compactness and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

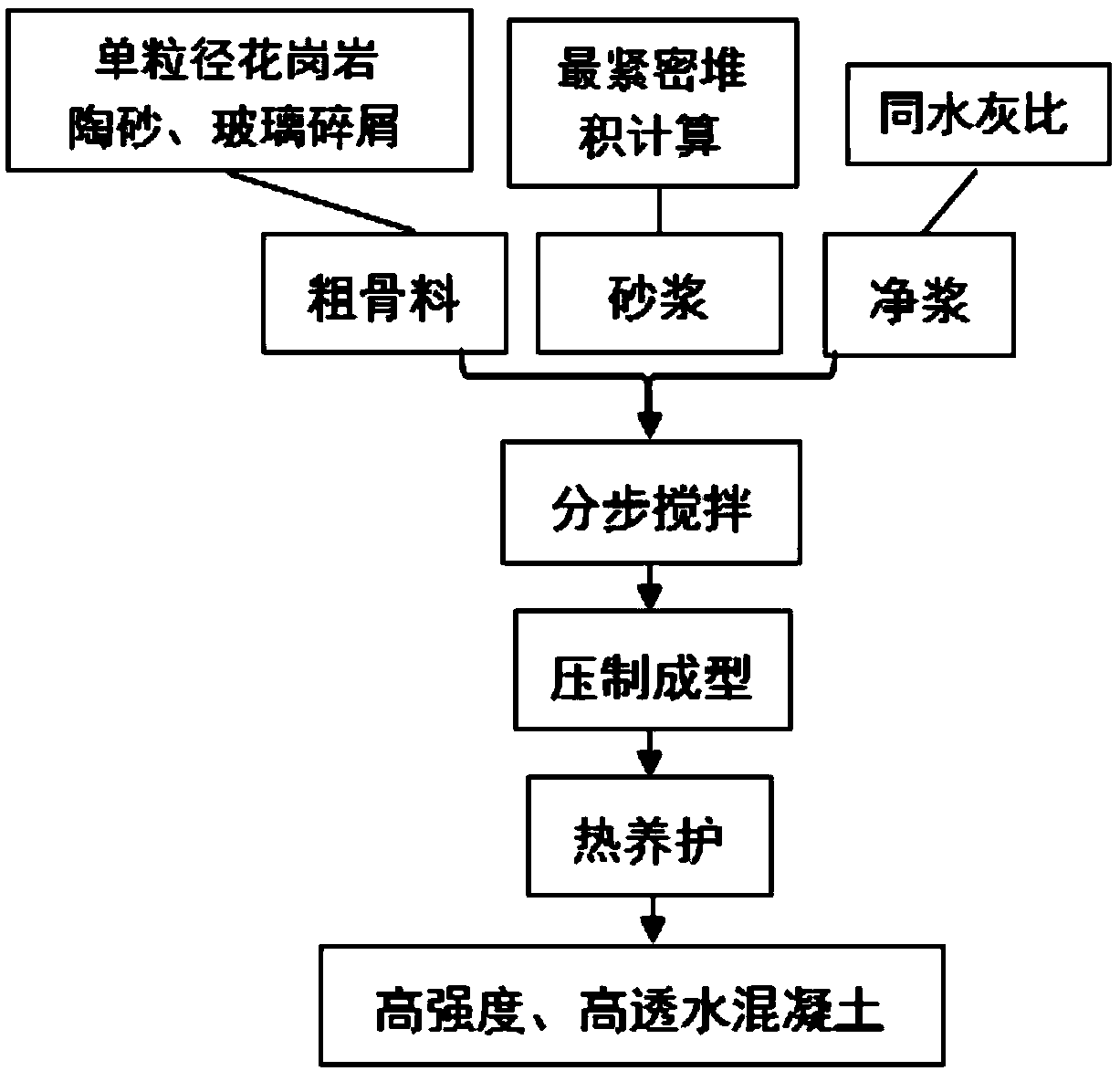

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

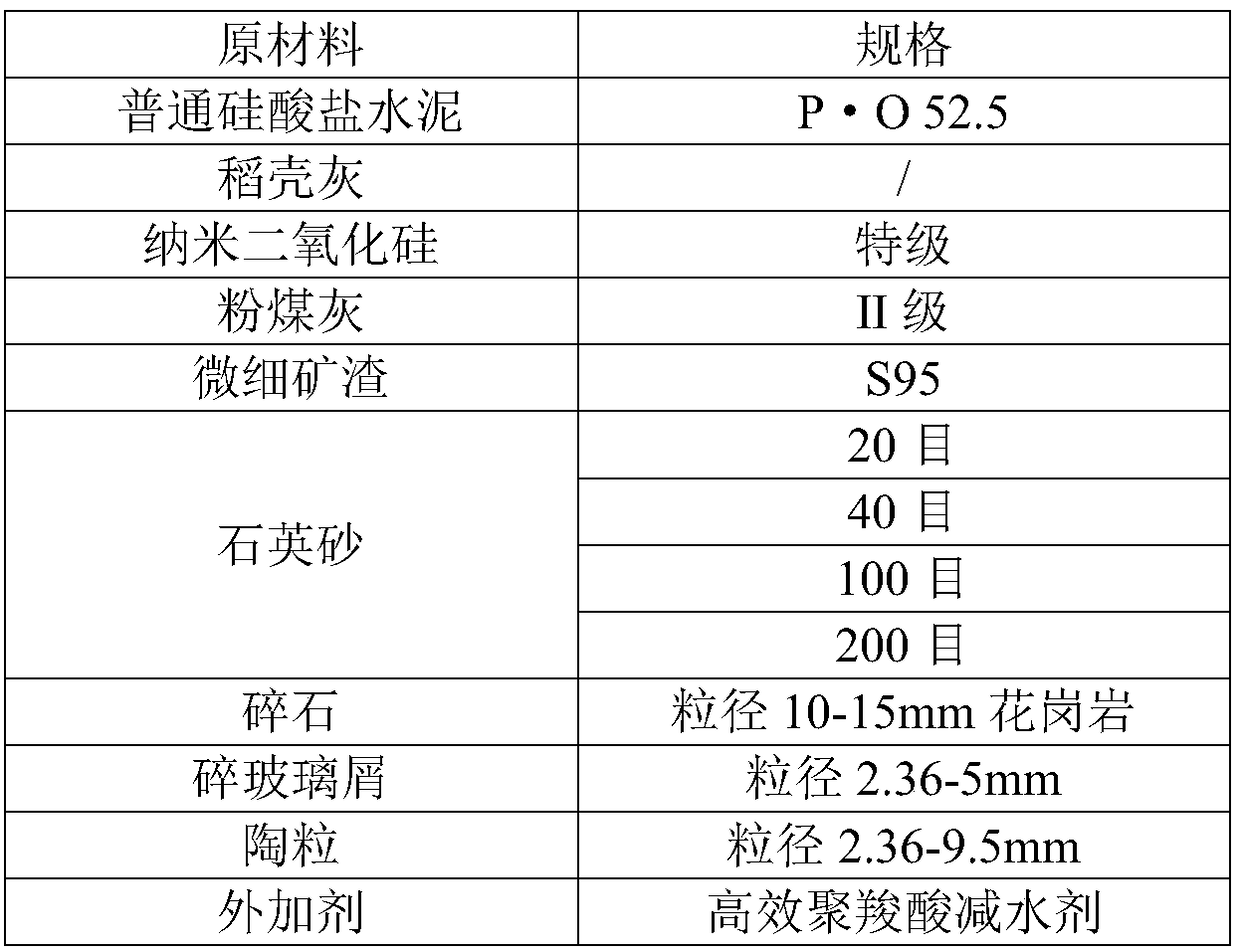

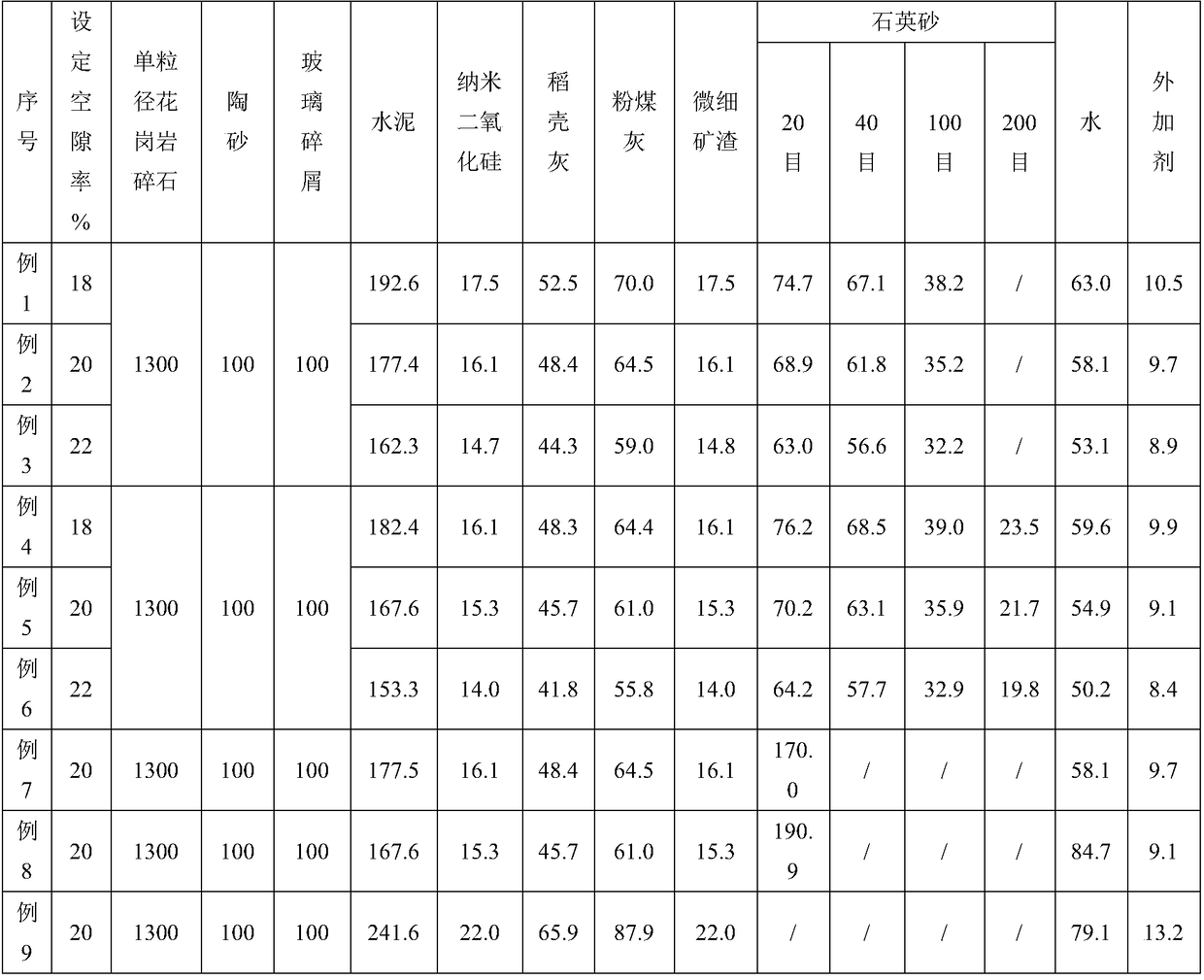

[0024] Referring to as shown in Table 1, a kind of high-strength, high-permeable concrete described in this embodiment comprises the following raw materials: granite gravel, ceramsite, glass debris, cement, rice husk ash, nano silicon dioxide, pulverized coal Ash, fine slag, continuous particle size quartz sand, water, superplasticizer.

[0025] The proportioning of quartz sand gradation and cementitious material (cement, rice husk ash, nano silicon dioxide, fly ash, fine slag) described in the above-mentioned raw material is according to Andreasen's classical theory q is the Fuller index, the value is 0.33-0.5, D p is the current particle size, D pl is the largest particle size) by the closest packing theory calculation, the specific process is, after selecting a Fuller index q, the continuous particle size of the quartz sand and the cementitious material are calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com