Mineral floatation column

A mineral flotation and flotation column technology, applied in flotation, solid separation, etc., can solve the problems of lost recovery rate, lower recovery rate of flotation column, and insufficient mineralization of useful fine-grained materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

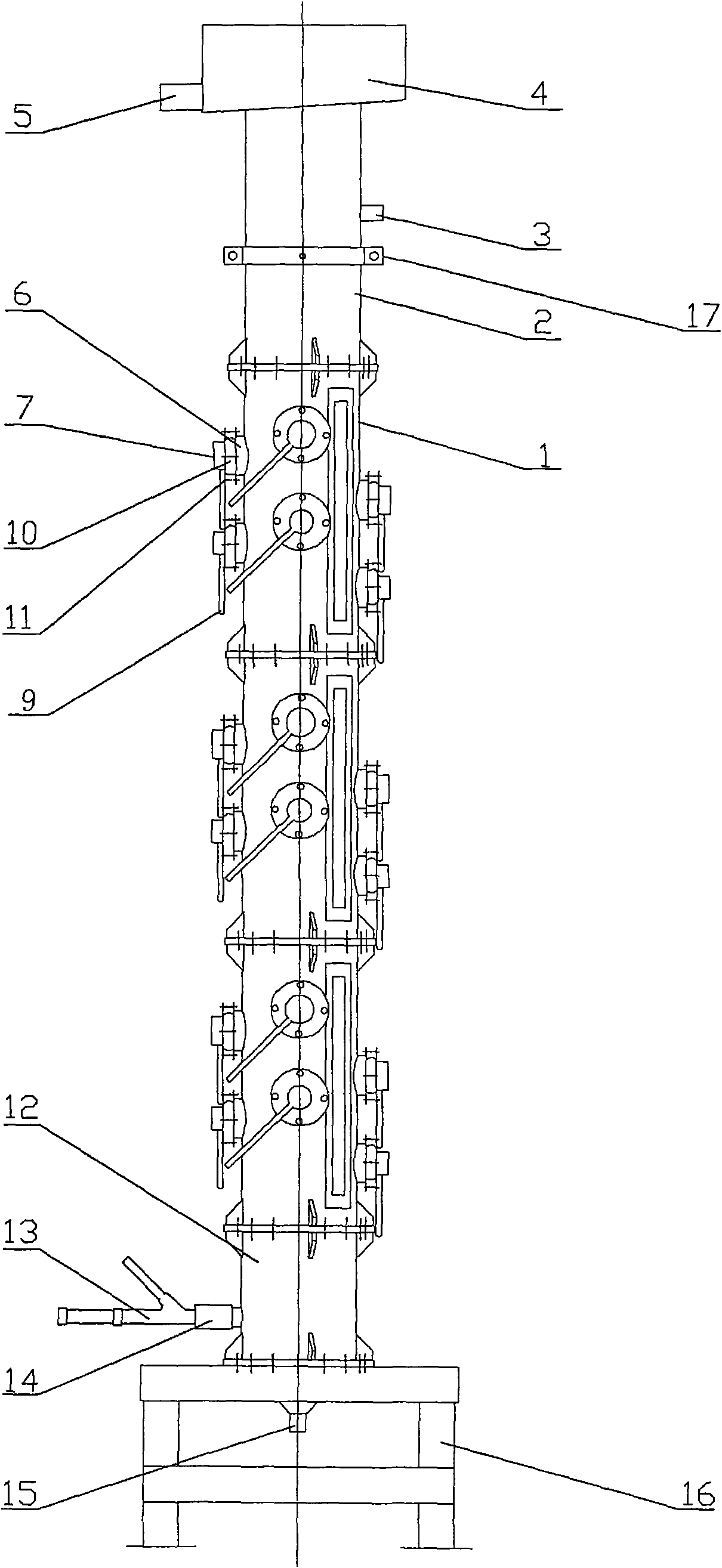

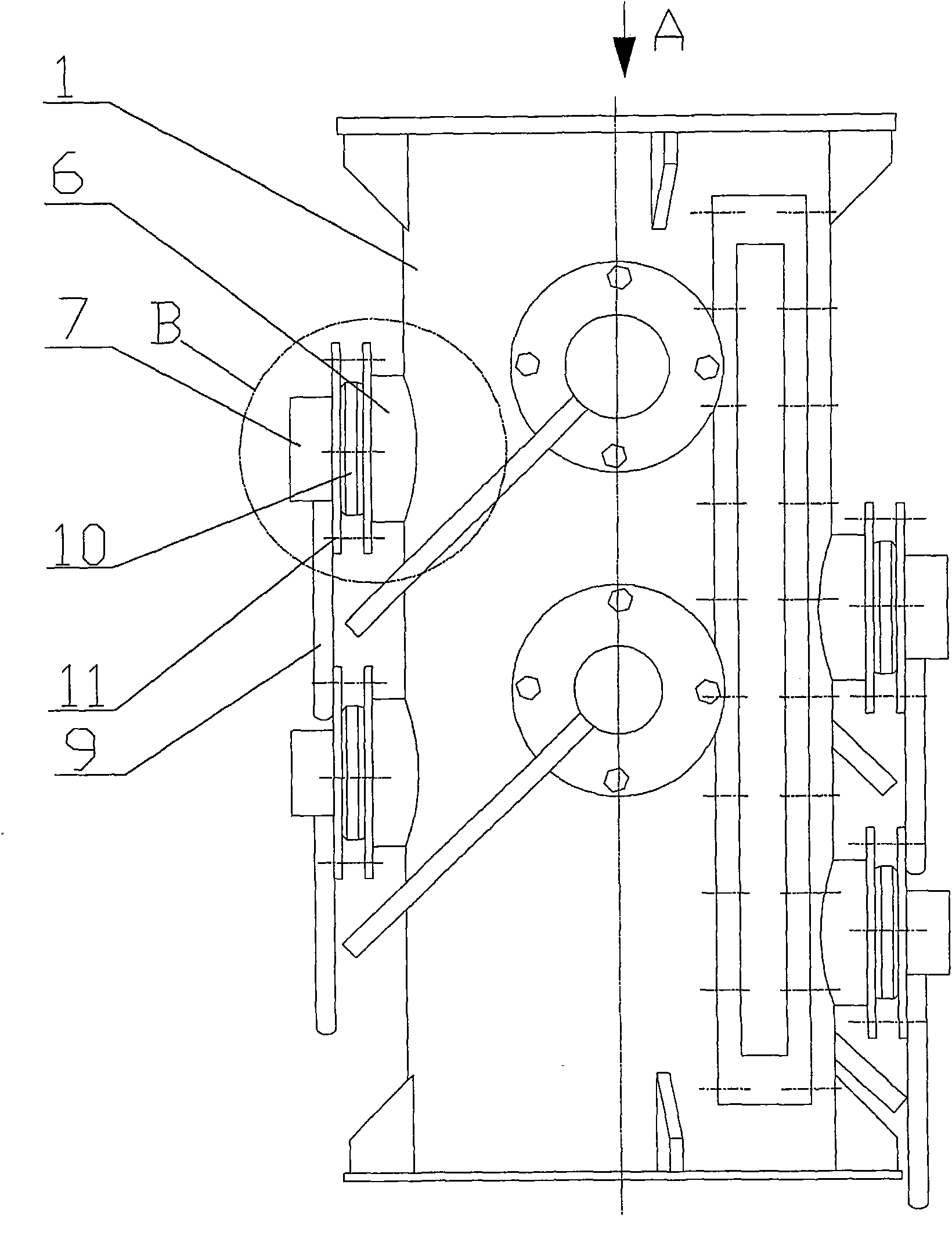

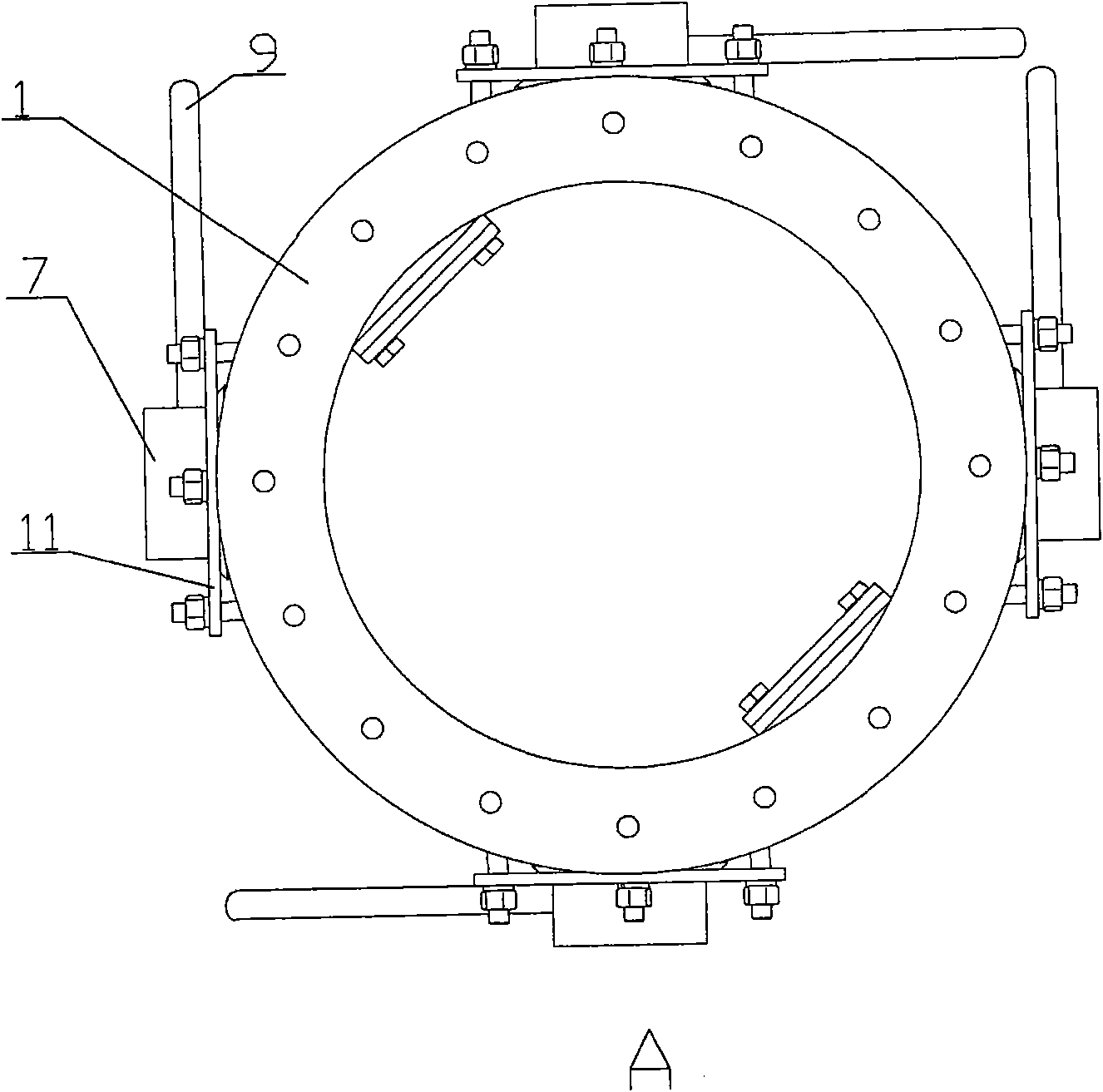

[0031] A kind of mineral flotation column, its structure comprises:

[0032] Flotation column body 1 - the body is a steel tubular body with a circular through-hole and a vertically arranged transparent strip-shaped observation window on the side wall of the body;

[0033] The ore inlet pipe section 2 - the ore inlet pipe section is a joint pipe cylinder with the same diameter as the flotation column body and flanged to the upper end of the flotation column body. A horizontal ore inlet pipe is arranged on the side wall of the ore inlet pipe section 3;

[0034] Foam tank 4 - the foam tank is a hollow tank body with an open upper end, the lower bottom of the tank body has a through hole fixedly connected with the upper end of the ore feeding pipe section, and a foam discharge pipe 5 is opened at the lower part of the side wall of the tank body;

[0035] Ultrasonic generating device mounting seat 6 - the mounting seat is a section tube-shaped seat fixed on the side wall of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com