Method for applying ferric dust in sintering

A technology of iron dust and sludge, which is applied in the field of metallurgical waste recycling, can solve the problems of high investment, complex process of iron-containing dust and sludge, and complex process, and achieve simple process, obvious economic and environmental benefits , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

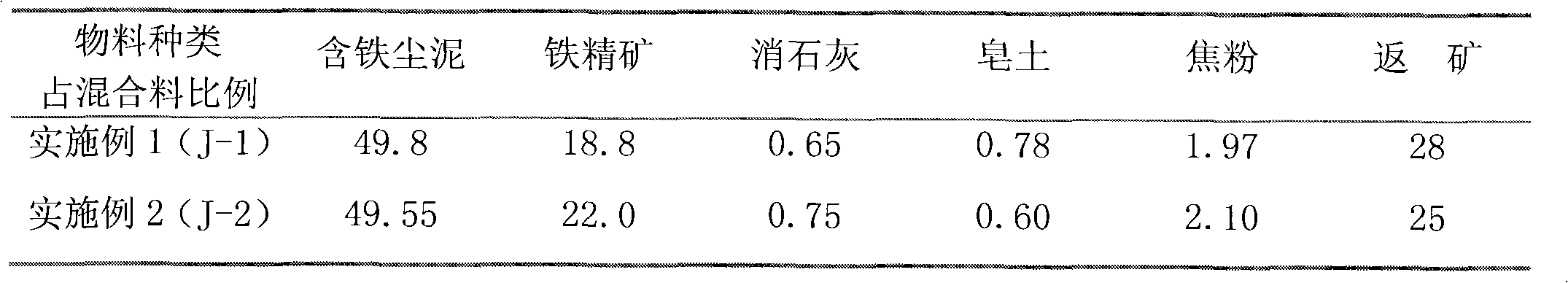

Embodiment 1 and Embodiment 2

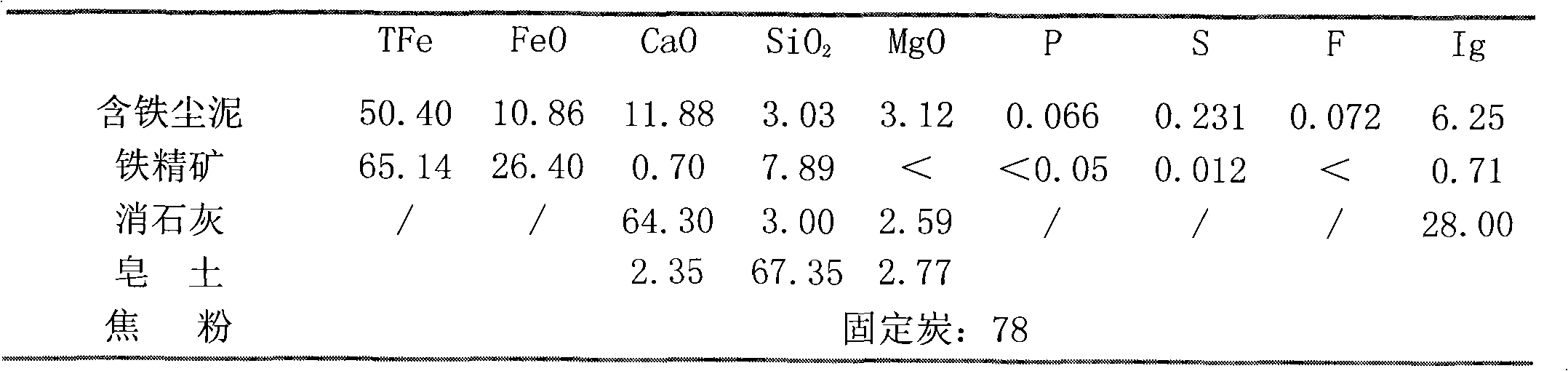

[0018] After mixing according to the ingredients shown in Table 2, the mixed material is pelletized with a pelletizing disc, the pellet size is 3-8mm, the particle size of 3-8mm accounts for 70% to 80%, and the pelletization time is 2 to 3 Minutes, the moisture content of the small pellets is controlled at 10% to 11%, and the composition of the sintered ore is set: the alkalinity is 1.85±0.5. MgO control 2.3% ~ 2.5%.

[0019] Specific sintering process parameter control: ignition time 1.5 to 2 minutes, ignition negative pressure 4900Pa, sintering extraction negative pressure 6860Pa, material layer thickness 500mm. The ignited mixture starts to sinter from top to bottom. After sintering, the finished ore is used in the blast furnace.

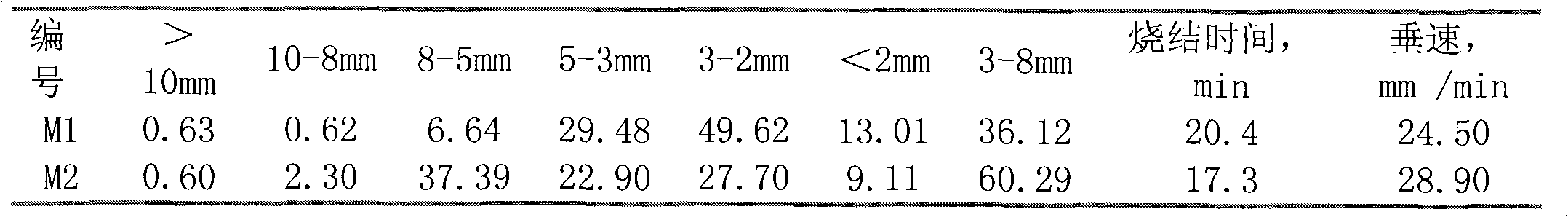

[0020] Table 4 lists the sintering process indicators and the main chemical components of sintering ore.

[0021] Table 4 Sinter cup test process indicators and main chemical components of sinter

[0022]

Embodiment 1

[0025] Example 1 4.47÷1000×450=2.01 (yuan / ton)

Embodiment 2

[0026] Example 2 3.87÷1000×450=1.74 (yuan / ton).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com