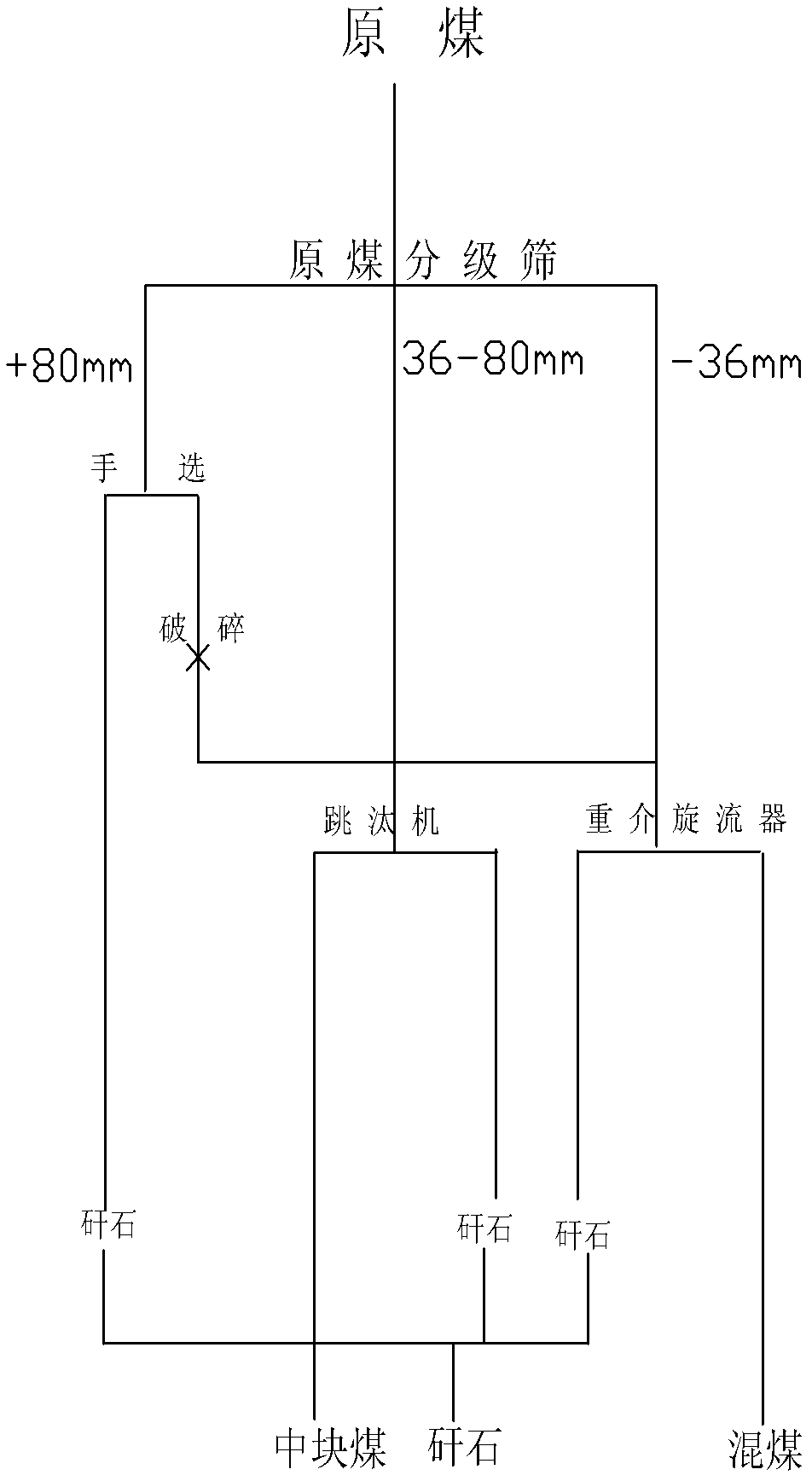

Graded washing process for raw coal

A raw coal and process technology, which is applied in the field of raw coal classification and washing process, can solve the problems of industrial application limitations, complex procedures, and many equipments, and achieve the effects of low production cost, simple process layout, and high separation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The raw coal grading sieve adopts a circular vibration method, two sieve plates, the first layer is a square hole sieve plate, and the sieve gap is 80mm, and the +80mm raw coal with a yield of only 6% is separated into manual selection; the second layer is a round hole The sieve plate, with a sieve gap of 36mm, separates the 36-80mm raw coal with a yield of 23.5%, and enters the jig for separation to produce high calorific value lump coal; the yield of -36mm raw coal is 70.5%, of which, the yield of -13mm It is 58.43%. After being sieved, it enters the final coal belt, transports it to the heavy medium raw coal storage bin, and enters the dense medium system for separation.

[0043] The jig machine is an under-screen air chamber type with a separate air supply system and numerical control system.

[0044] The heavy medium cyclone is a two-product cyclone, the heavy product is discharged from the bottom flow port, and the light product is discharged from the overflow por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com