Prestressed high-strength steel wire mesh anchorage device

A high-strength steel wire and prestressing technology, applied in bridge erection/assembly, bridge maintenance, bridge reinforcement, etc., can solve the problems of the steel wire rope not reaching the limit tension, wire rope damage, anchor cup deformation, etc., and achieve reliable anchoring performance and convenient centering , the effect of loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1. Application of prestressed high-strength steel wire mesh anchorage

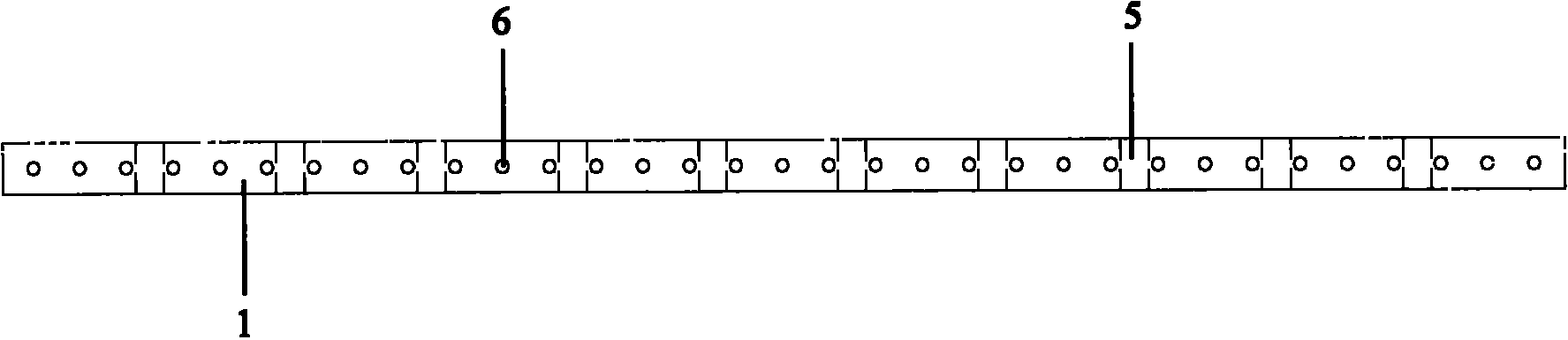

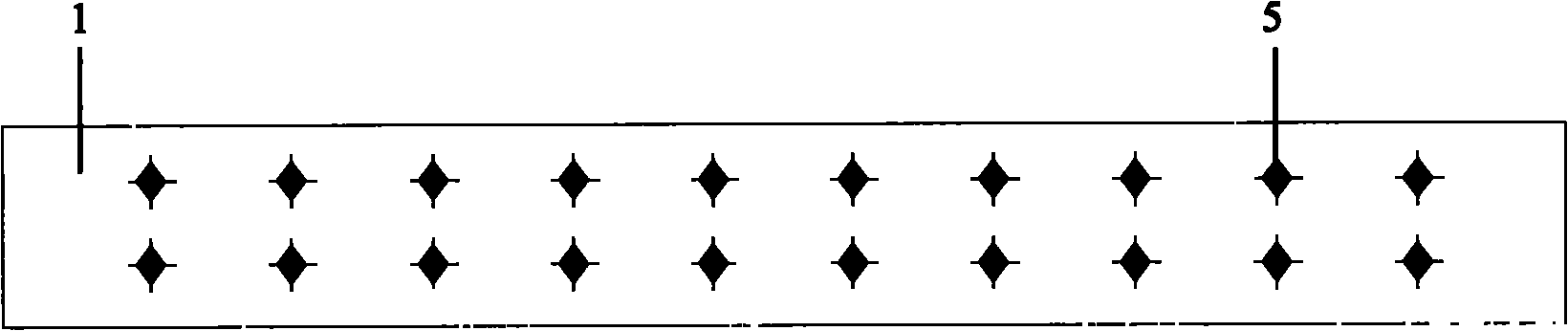

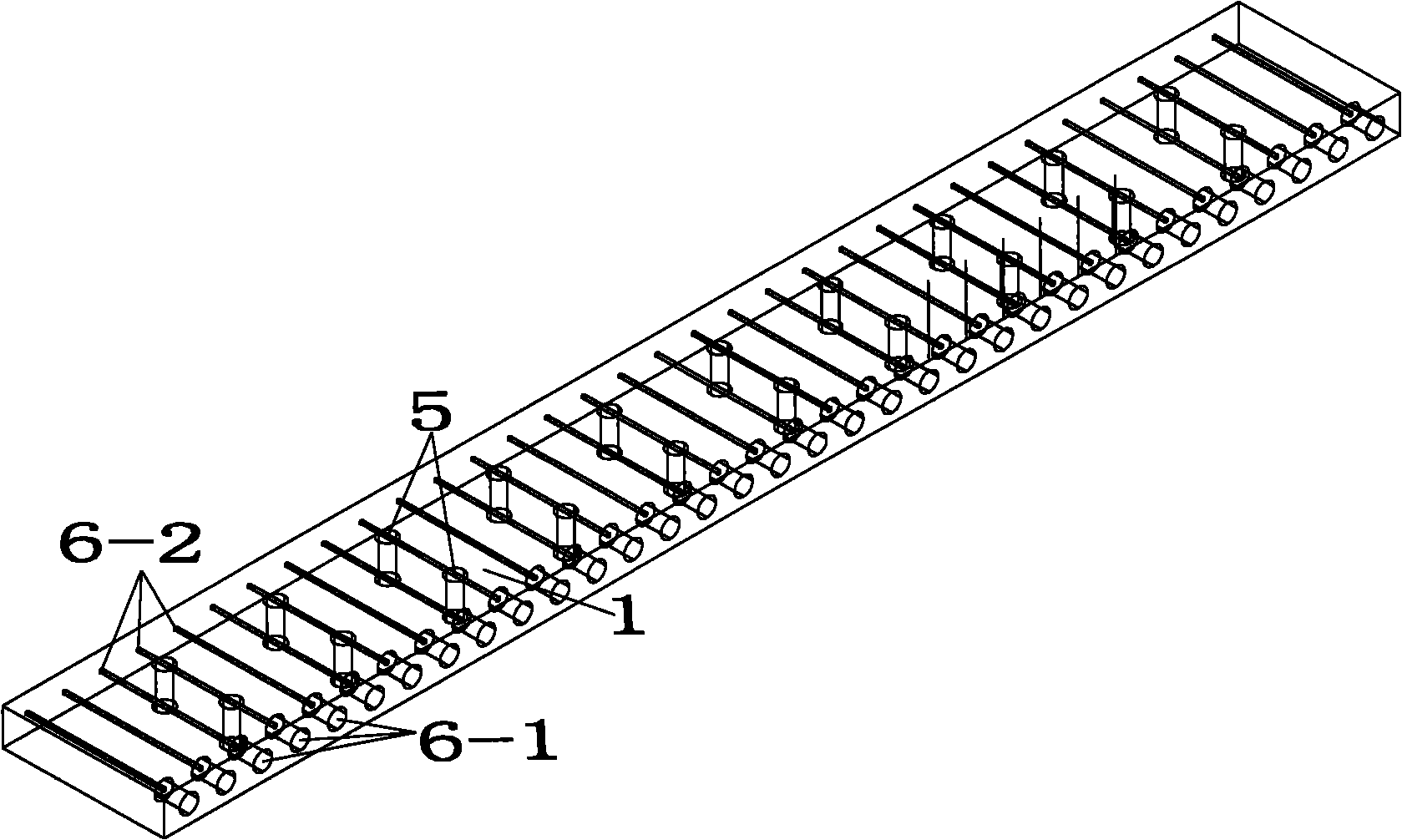

[0033] Such as Figure 1 to Figure 7 As shown, the prestressed high-strength steel wire mesh anchor includes an anchor 1 , a bolt 2 , a screw 3 and a clip 4 . The anchor is a cuboid with a length of 1m, a width of 13cm, and a height of 3cm. There are 20 through-holes I(5) between the upper and lower bottom surfaces, and 33 horizontally arranged through-holes II(6) between the front and rear bottom surfaces. ; The through hole II (6) is composed of a threaded bolt area 6-1 on the wall and a high-strength steel wire rope guide area 6-2 for high-strength steel wire ropes to pass through. The outer wall of the screw 3 is provided with threads; the screw 3 is provided with a through hole III in the axial direction matching the diameter of the high-strength steel wire for the high-strength steel wire to pass through. The clip 4 is axially provided with a through hole IV matching the diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com