Mineral insulated cable of large length

A mineral insulated, fire-resistant cable technology, applied in the direction of insulated cables, insulated conductors, inorganic insulators, etc., can solve the problem that fire-resistant cables cannot be non-combustible, meet the needs of emergency evacuation and fire protection, high thermal conductivity and overload resistance, The effect of excellent electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

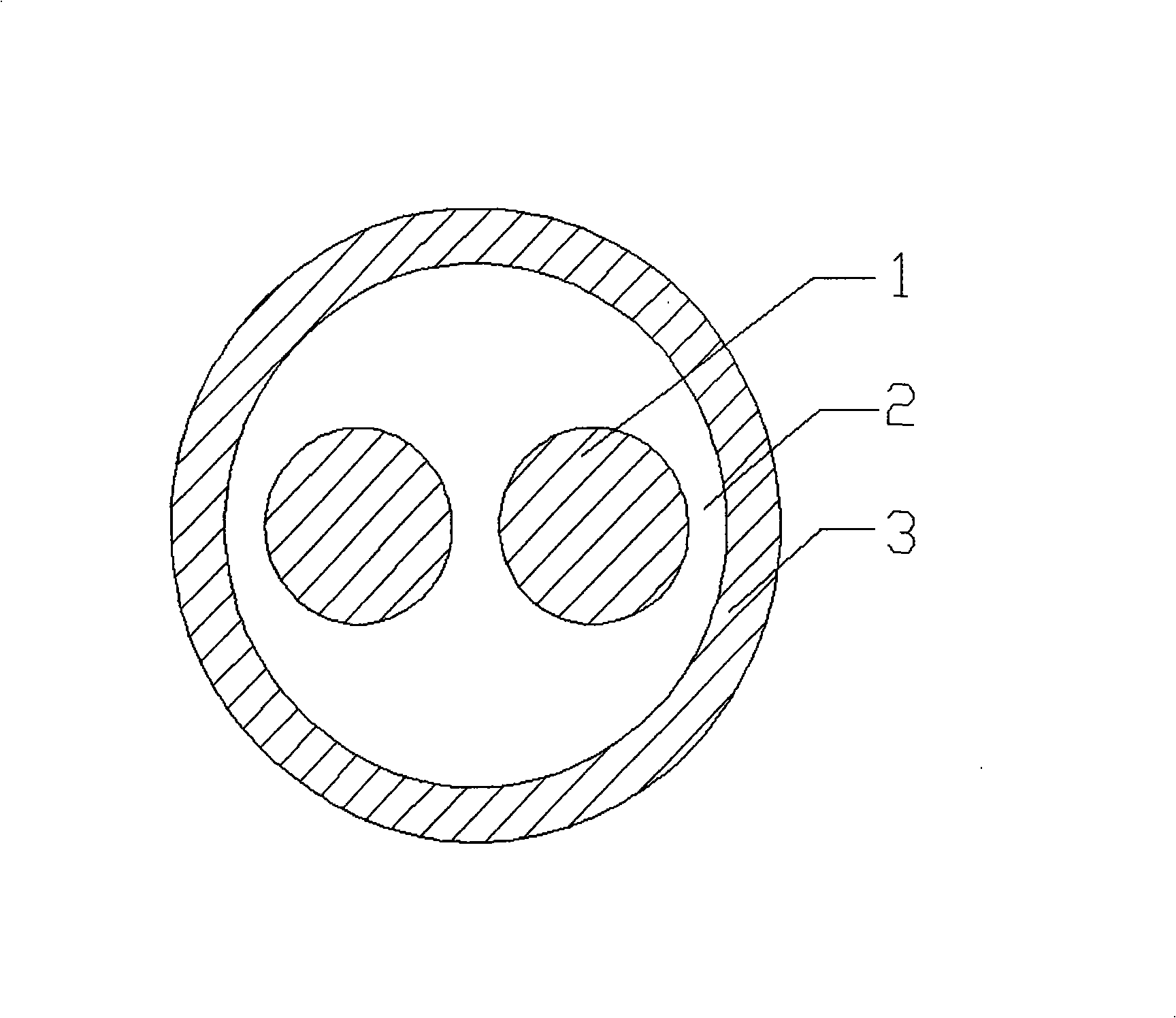

[0011] Below in conjunction with accompanying drawing, the present invention will be further described

[0012] New MIC long-length mineral insulated fireproof cable is composed of copper conductor 1, insulating layer 2 and copper sheath 3, copper conductor 1 is covered by insulating layer 2, insulating layer 2 is covered with copper sheath 3, and the conductor is in accordance with the regulations of GB / T3956 , A class A single solid core conductor is used, the insulating layer 2 is formed by compacting and filling magnesium oxide powder with a vibration compacting device, and the copper sheath is formed by argon arc longitudinal seam welding of copper tape roll forming.

[0013] The product can be widely used in explosion-proof systems and equipment, fire hazard areas (petrochemical industry, nuclear power plants, etc.), high-temperature occasions (metallurgical industry, power plants, etc.), underground lines (subway, tunnels, mines, etc.), and places requiring special safet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com