Device for detemining requiring or not to charge synthetic fibre rope

A technology for synthetic fibers and ropes, which is applied in the field of devices for identifying whether to replace synthetic fiber ropes, can solve the problems of not being able to explain the internal state of the ropes, the loss of the ropes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

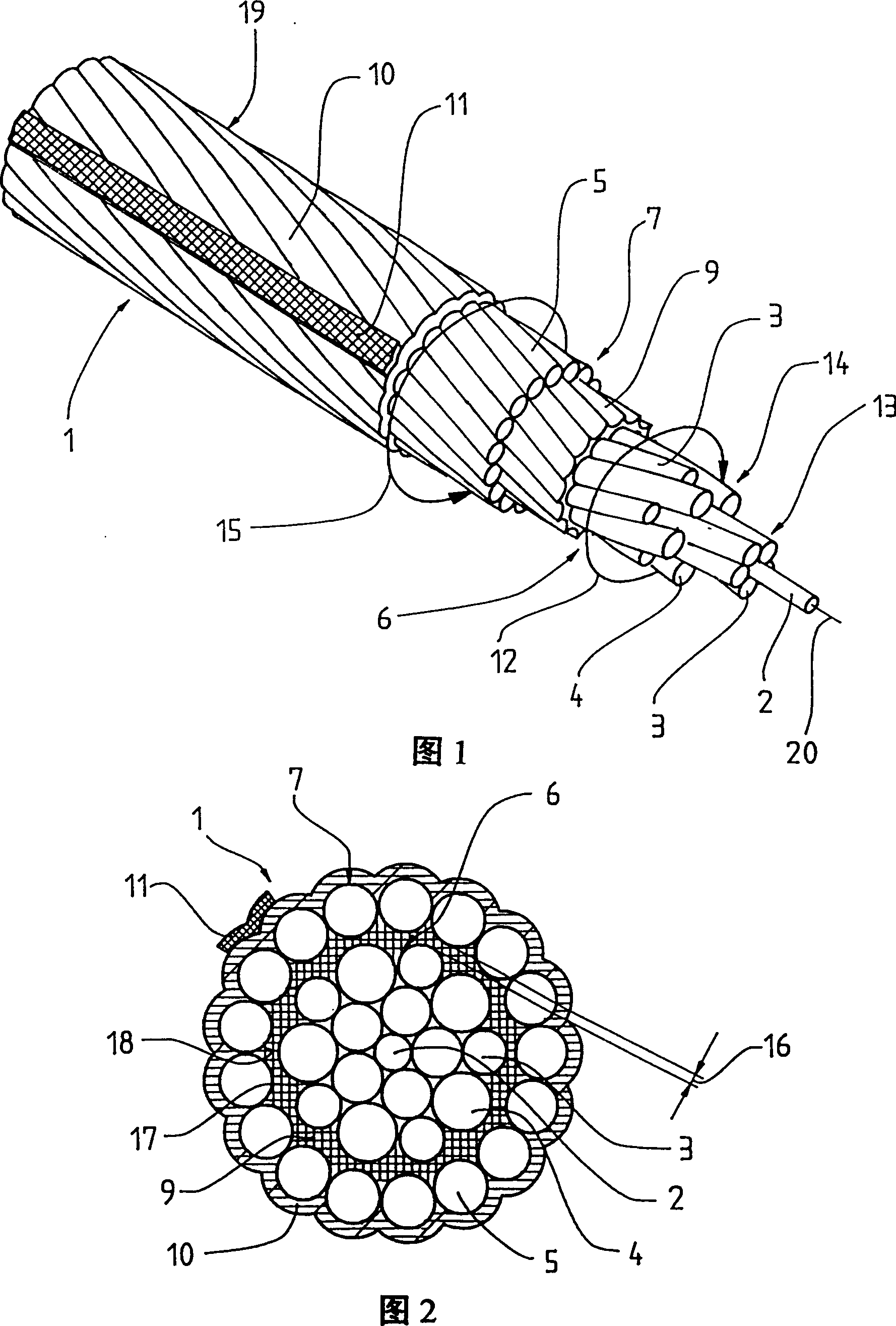

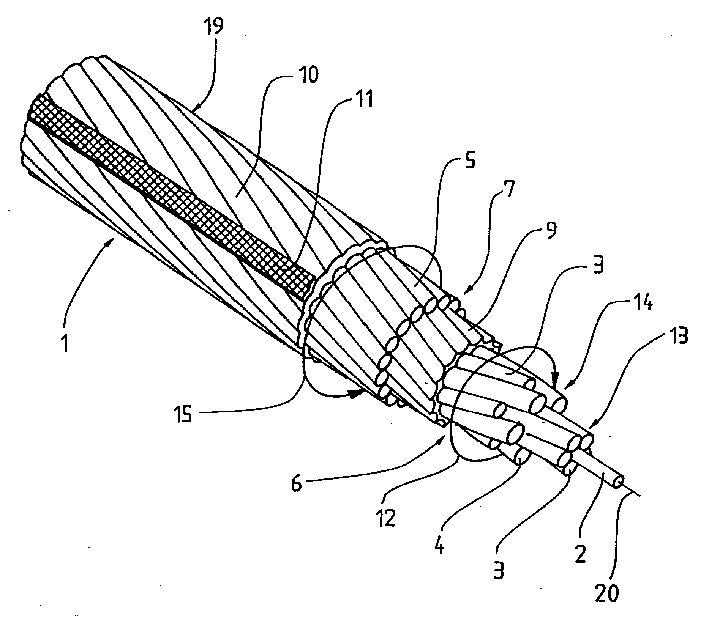

[0014] Figure 1 shows a sheathed aramid fiber rope 1, which consists of three layers of high tensile strength, load-bearing aramid fiber strands 2, 3, 4, 5 twisted together. Composed of concentric layers, these twisted strands are used, for example, as drive ropes in lifting devices. In fact, the aramid fiber rope 1 is constructed with a parallel twisted rope core 6 around which, according to the invention, a strand (also called outer sheath) is twisted in opposite directions. 7. Between the strand layer 7 and the second strand layer 14 of the adjacent core layer 6 is an intermediate sheath 9, preferably made of polyurethane. The cord sheath 10 is around the outside of the strand layer 7 and is well bonded thereto. Along the longitudinal direction of the entire length of the aramid fiber rope 1, a wear-resistant indicating device (in the present invention, also referred to as colored lines, colored lines or marks) 11 is coated on the rope sheath 10 to indicate the aromatic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com