High-temperature resistant prestressed steel stranded wire

A technology of prestressed steel strands and high temperature resistance, which is applied in the direction of textiles, papermaking, textile cables, etc. It can solve the problems of steel brittleness, difficulty in large-scale promotion, and falling off of fireproof coatings, and achieve good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

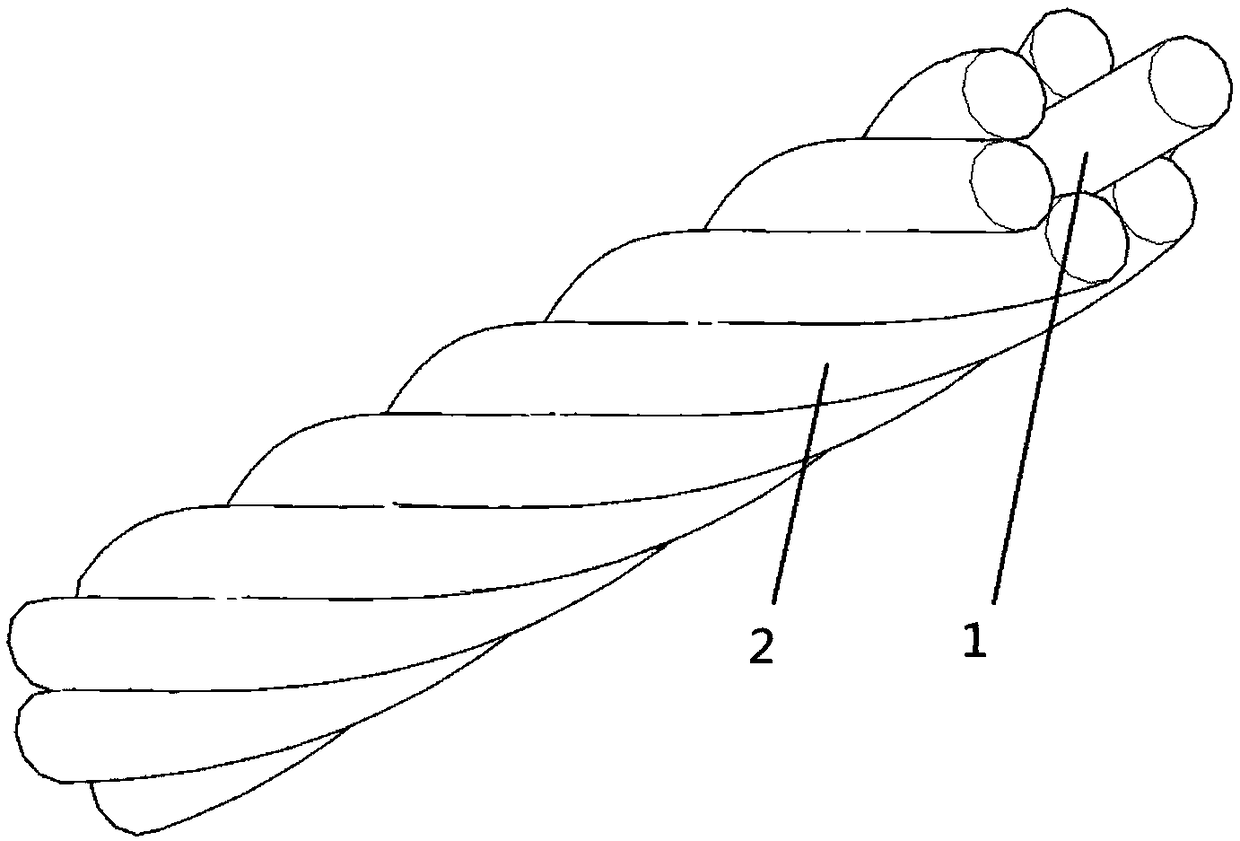

[0019] A high temperature resistant prestressed steel strand, its structure is as follows figure 1 As shown, including the inner core 1 and the stranded wire 2 wound outside the inner core 1, the inner core 1 is a shape memory alloy inner core with a diameter of 5.25±0.05mm, and the austenite finishing temperature is 200-400°C. In the embodiment, the stranded wire 2 is provided with 6 strands of steel wires with a diameter of 5.07±0.05mm, and the stranded wires made of steel are used, which are spirally wound on the outside of the inner core.

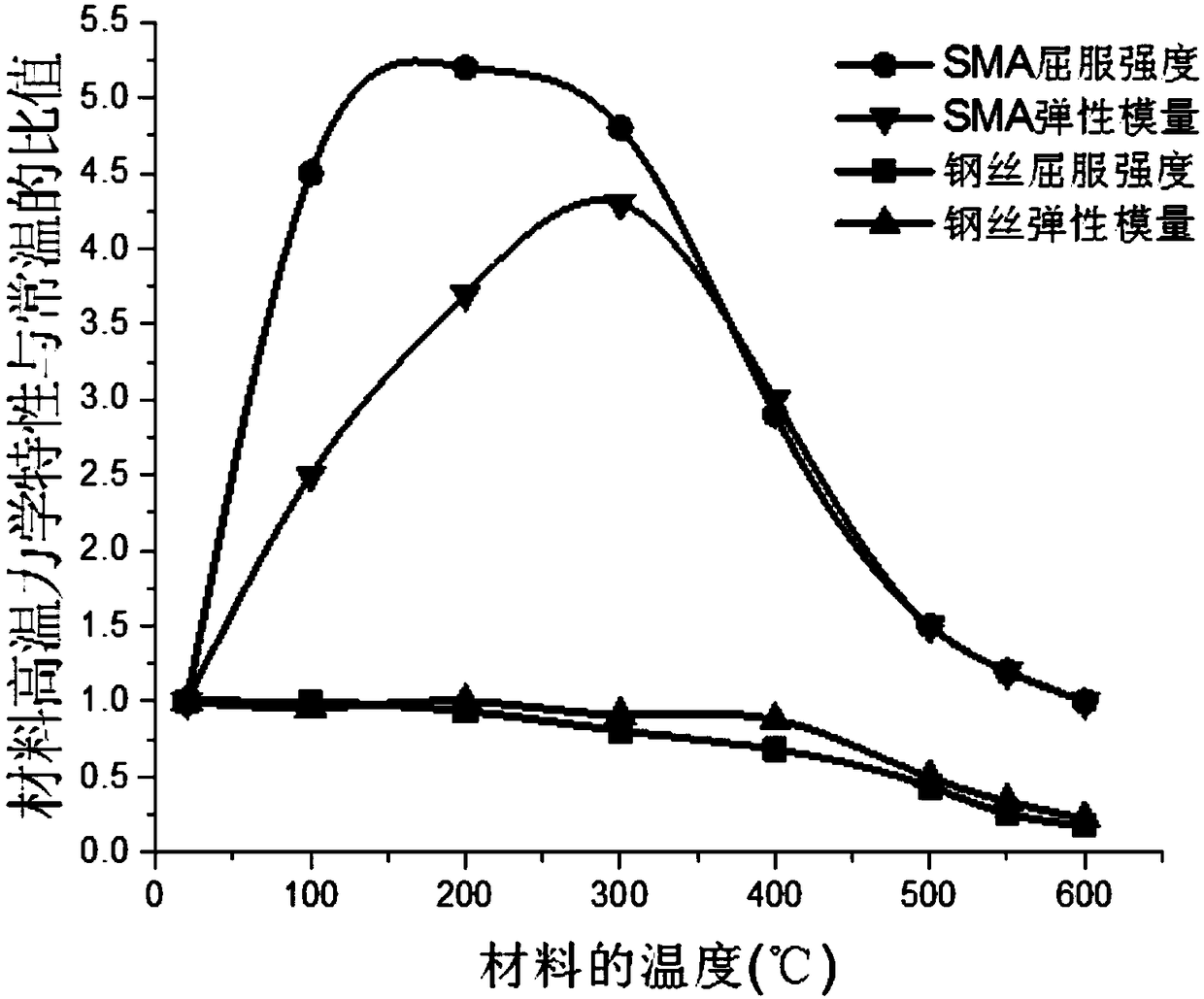

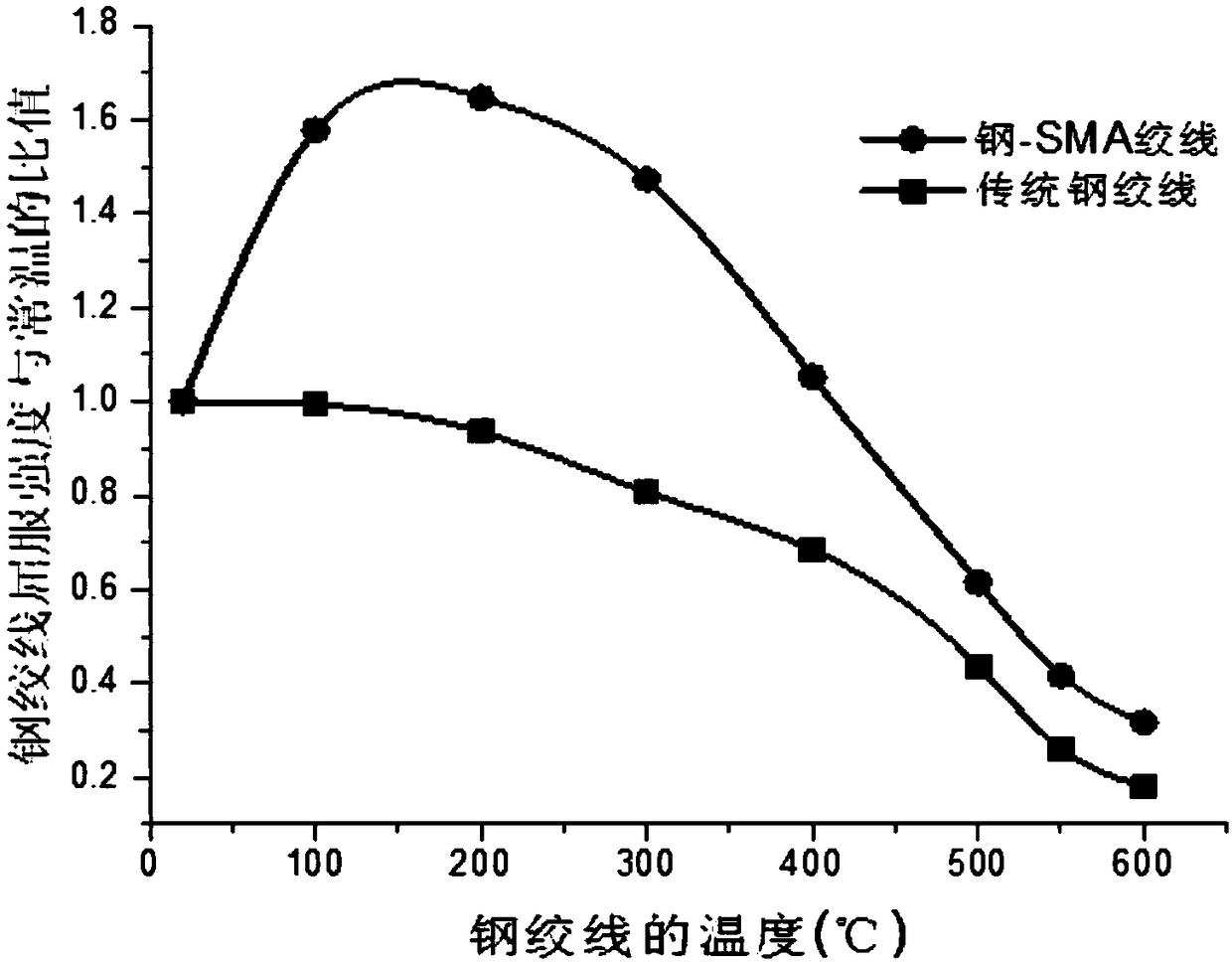

[0020] Shape memory alloy (SMA) has a unique shape memory effect, and SMA will transform from martensite phase to austenite phase and return to the original shape at high temperature. If the traditional prestressed steel wire is stranded with SMA to make a steel strand, and prestress is applied to both ends, the SMA will produce considerable restoring force at high temperature, which can offset the prestress loss of the traditional stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com