Automatic winding machine of motor iron core

An automatic winding machine and iron core technology, which is applied in the field of winding machines, can solve problems such as low winding efficiency, troublesome assembly of iron cores, and low work efficiency, and achieve the effects of improving winding quality, saving time, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0035] The winding machine of the present embodiment can realize the automatic winding of the iron core, and the iron core used for winding in the present embodiment can be an in-line or segmented motor core, and the coil of winding adopts enameled wire 8, like Figure 11 As shown, it is a schematic diagram of the structure of the in-line iron core workpiece after the coil winding has been completed. The connected arc-shaped unit tooth blocks 91, two adjacent arc-shaped unit tooth blocks 91 are connected to each other by a connecting part in the direction of the outer edge that can be bent by an external force;

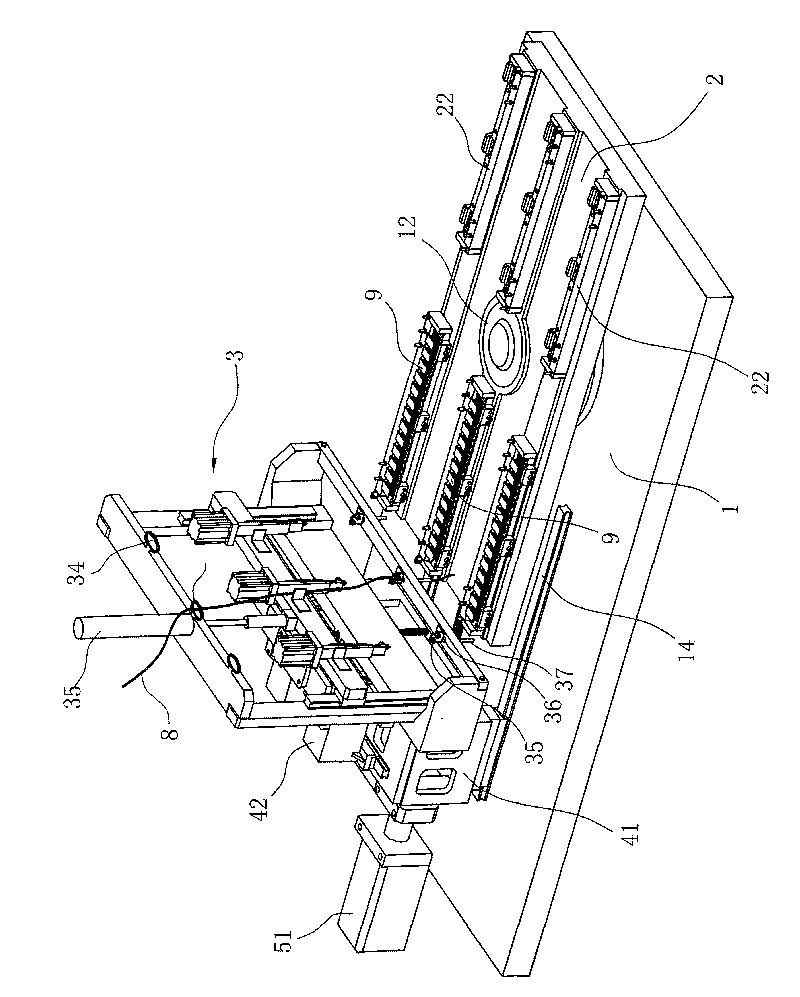

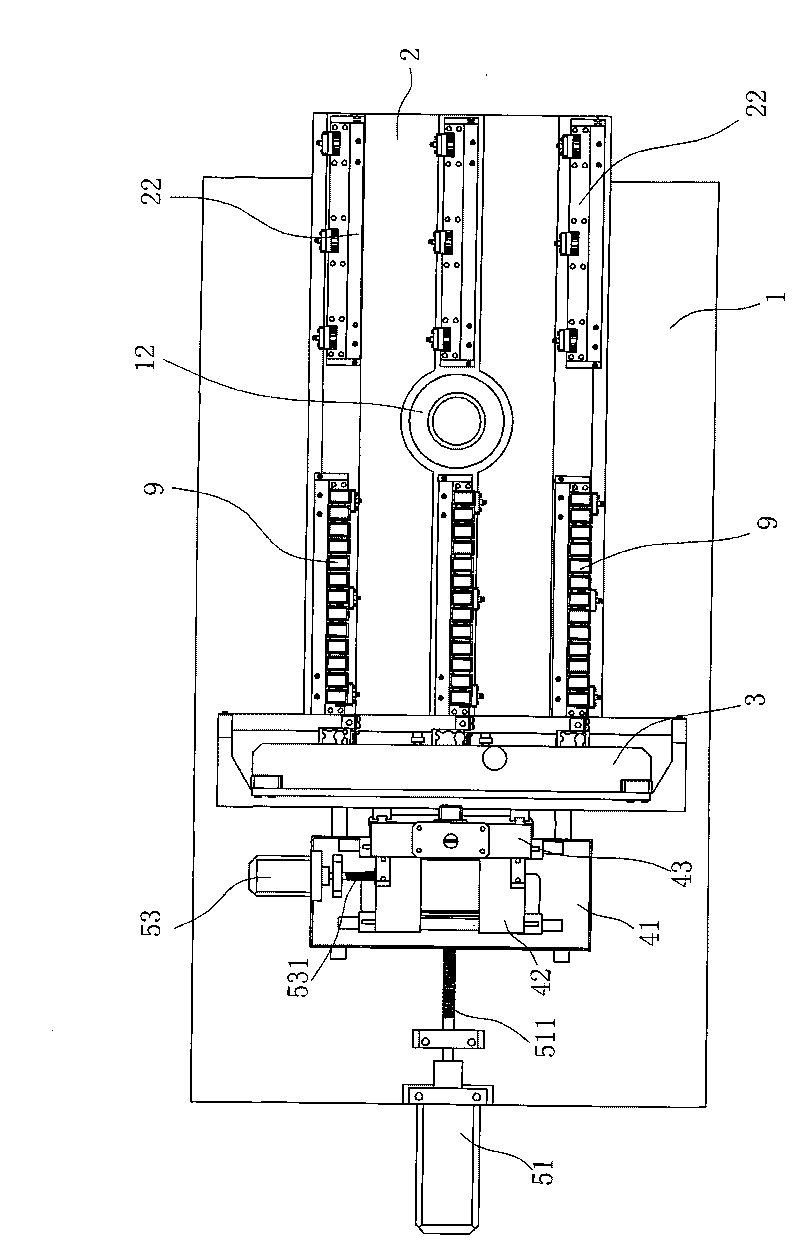

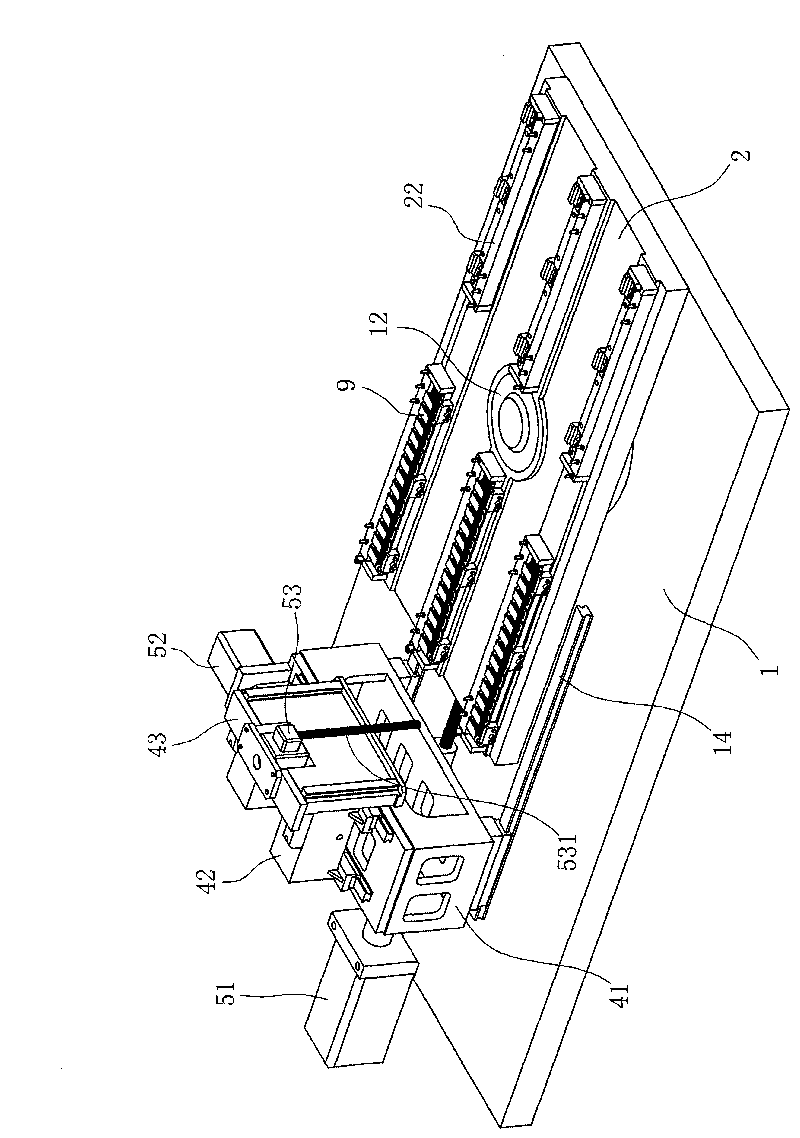

[0036] like Figure 1 to Figure 10 As shown, it is a schematic view of the structure of the winding machine of the embodiment. The winding machine of the present embodiment is arranged in the frame, and the wire wheel for pulling th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com