Detection device for steel tube weld seams through X-ray real-time imaging

A detection device, real-time imaging technology, applied in the direction of material analysis using radiation, etc., to achieve the effect of saving money and energy, saving steel, and reducing installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

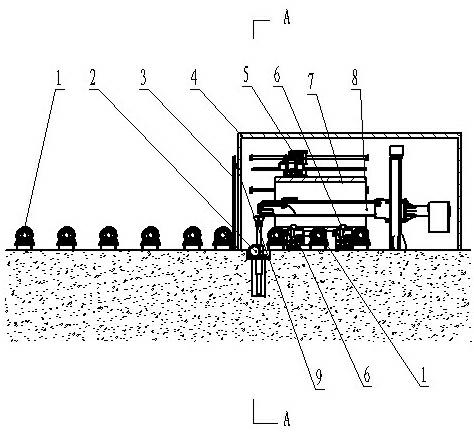

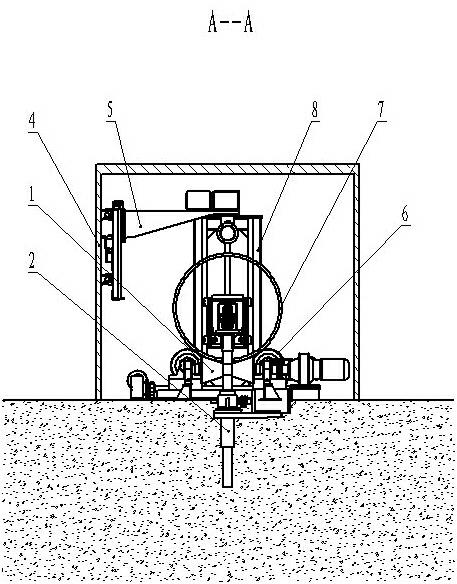

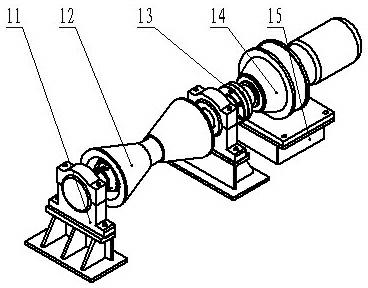

[0020] A steel pipe weld X-ray real-time imaging detection device, such as figure 1 with figure 2 As shown, it includes the steel pipe inspection conveying line composed of the conveying roller joint 1 fixed on the ground of the workshop and the steel pipe inspection conveying line connected with the steel pipe inspection conveying line set at the end of the steel pipe inspection conveying roller joint 1. The detection and protection room 4 is located on the same ground foundation, wherein: at the bottom of the detection protection room 4, 3 to 6 groups of conveyor rollers with the same structure and the same spacing as the steel pipe detection conveyor line are set to carry the spare inspection workpiece 7 1. Set the lifting and rotating wheel assembly 6 between the conveying roller assembly 1, and install the X-ray receiving device assembly 8 at the detection cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com