Single-phase intelligent energy meter distributed correction method

A smart electric energy meter, distributed technology, applied in the direction of measuring electric variables, measuring devices, instruments, etc., can solve the problems of incomplete synchronization of time, poor consistency of electric energy meters, large accidental errors in calculating meter calibration parameters, etc., to achieve accuracy and The effect of improving consistency, saving installation time, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

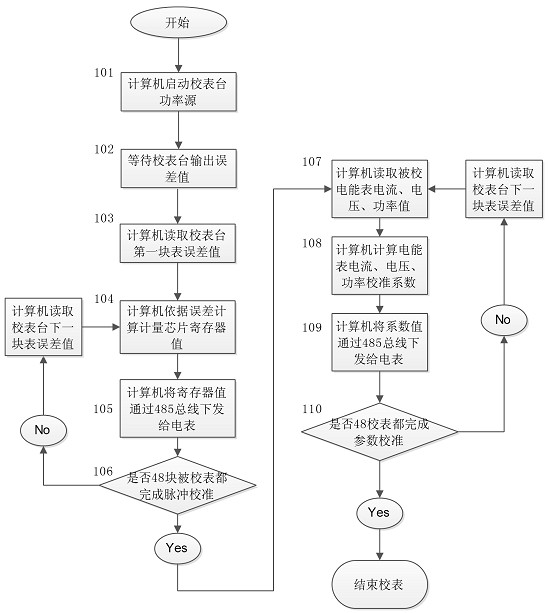

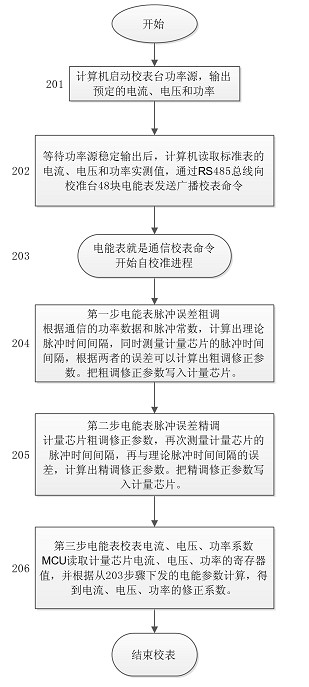

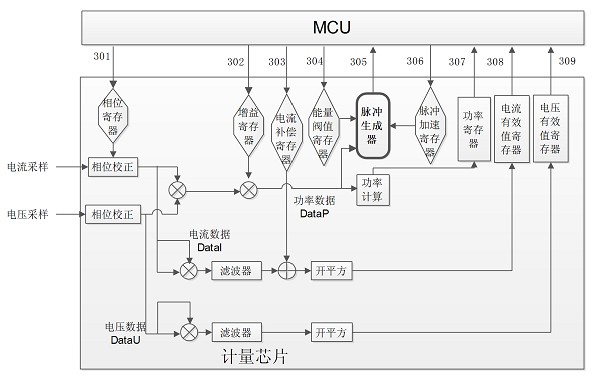

[0033] The following takes the calibration of the national grid single-phase smart energy meter as an example, combined with image 3 The distributed calibration method is further explained.

[0034] The basic current calibration 1.0 phase error calibration steps of the FireWire channel are as follows:

[0035] Step 1, the main control computer controls the power source of the meter calibration station to output rated voltage, rated current, and 1.0 phase through the RS232 bus; the main control computer reads the current voltage, current, and power values from the standard electric energy meter, and broadcasts In this way, a 1.0 phase error calibration command is issued through the RS485 bus. The main control computer enters the timing waiting state, and the following steps are completed by the MCU of each electric energy meter;

[0036]Step 2, pulse acceleration: All the watt-hour meters to be calibrated receive the command to start meter calibration at the same time, rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com