Construction method for lifting arch structure in zero-deformation state

A technology of an arched structure and a construction method, which is applied to the arched structure, the structure of the dome, and the building components, can solve the problems of high safety of the working surface, large horizontal force of the supporting structure, and high construction cost, and saves construction. The effect of measures cost, reducing additional stress and improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

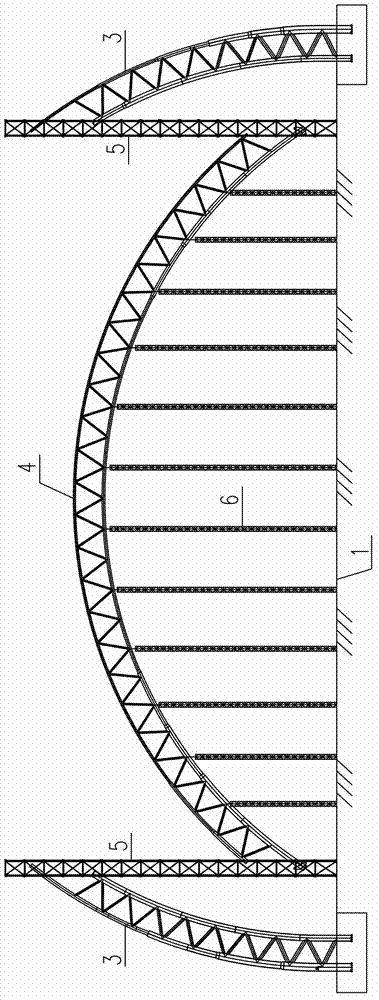

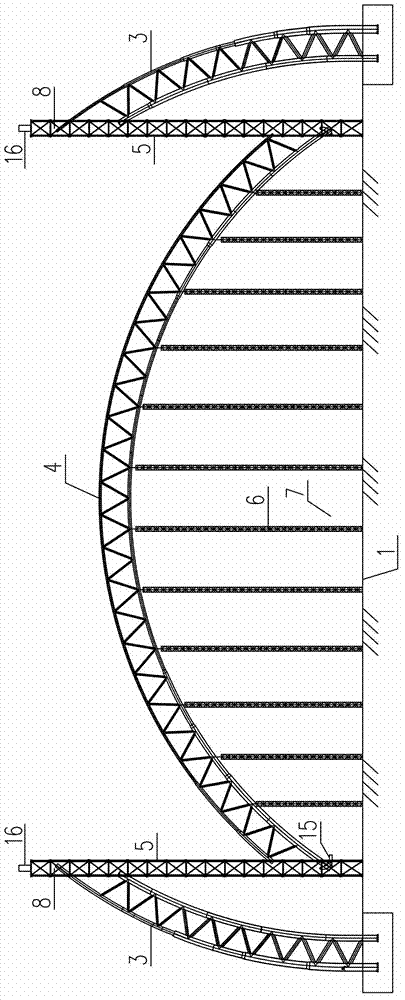

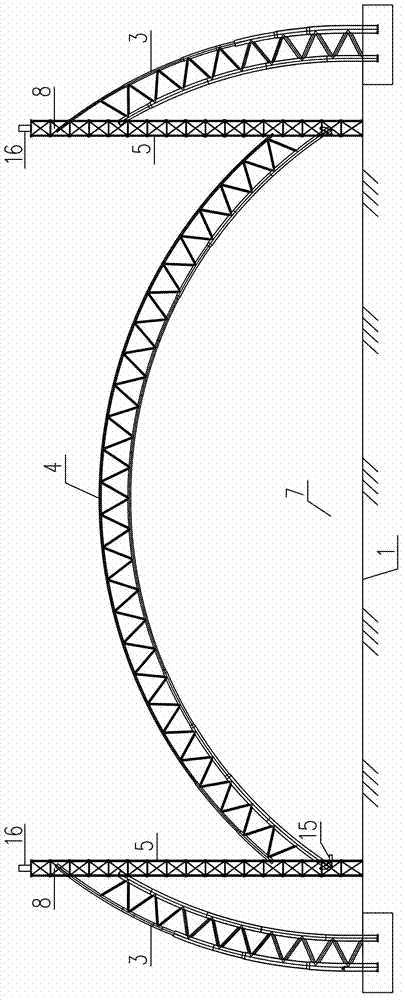

[0065] Preferred Embodiment 1: The specific implementation method of a self-balanced cumulative lifting construction method for a large-span arched structure described in the present invention is as follows Figures 1 to 6 As shown, in this embodiment, the building is a long-span arch structure with a semicircular cross section, and a structural system of inverted triangular main arch truss + secondary truss + single-layer reticulated shell roof purlin is adopted. Due to the moderate span of the structure, it is divided into three sections, and the construction method of one lifting is adopted. Specifically include the following steps:

[0066] (1) According to the construction conditions and structural characteristics, the large-span arch structure 2 is pre-segmented into the landing part arch structure 3 on both sides and the lifting construction unit 4 in the middle.

[0067] (2) Set up a number of supporting tire frames 6, assemble and lift the construction unit 4 in situ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com