Long-span load-carrying cable lifting machine and mounting method therefor

A cable crane and heavy-duty technology, which is applied in the direction of cable cranes, cranes, transportation and packaging, etc., can solve the problem that the lifting capacity cannot meet the needs, so as to reduce the amount of steel wire rope materials and tension workload, reduce The effect of deflection at the top of the tower and improvement of rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

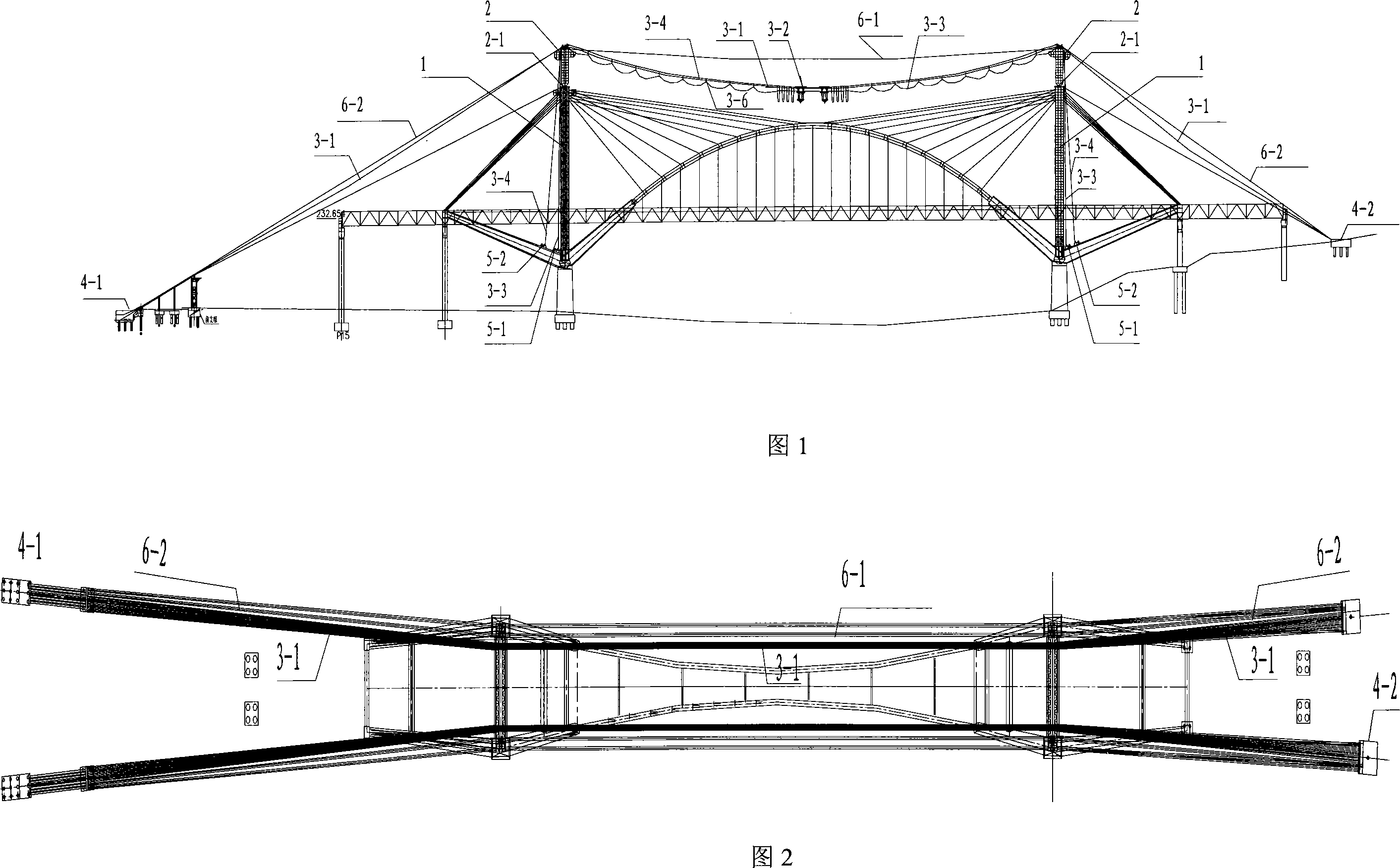

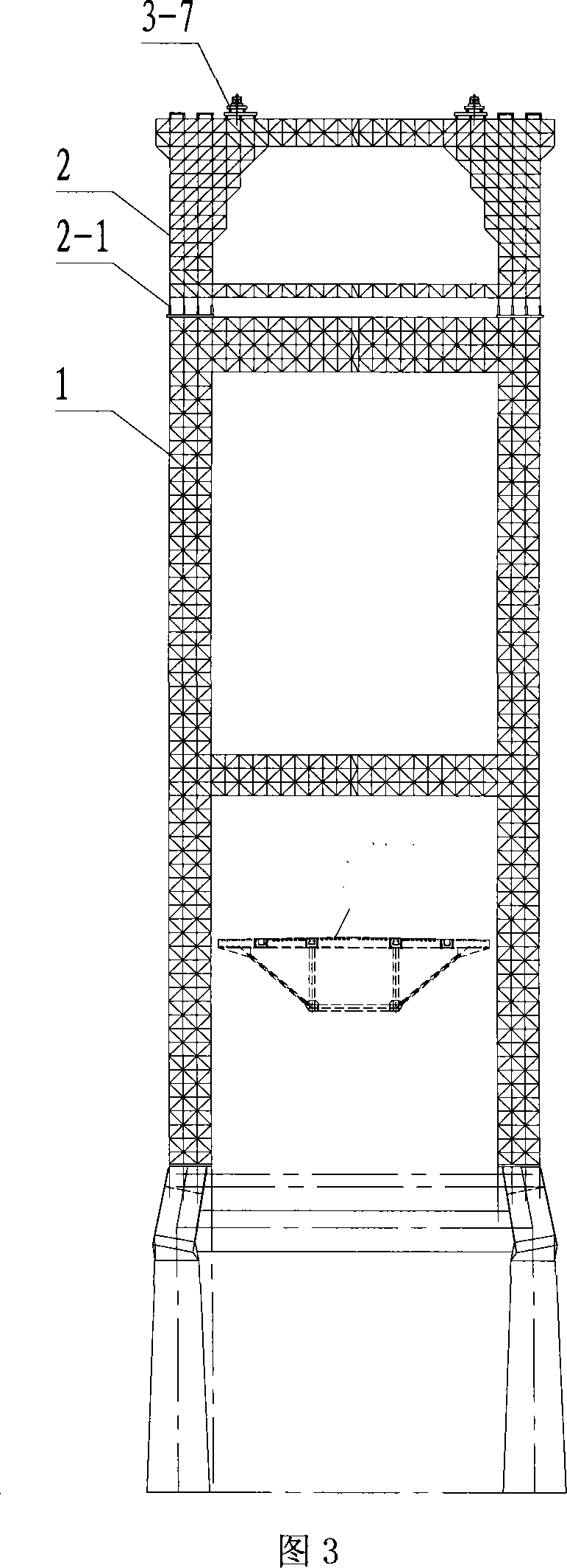

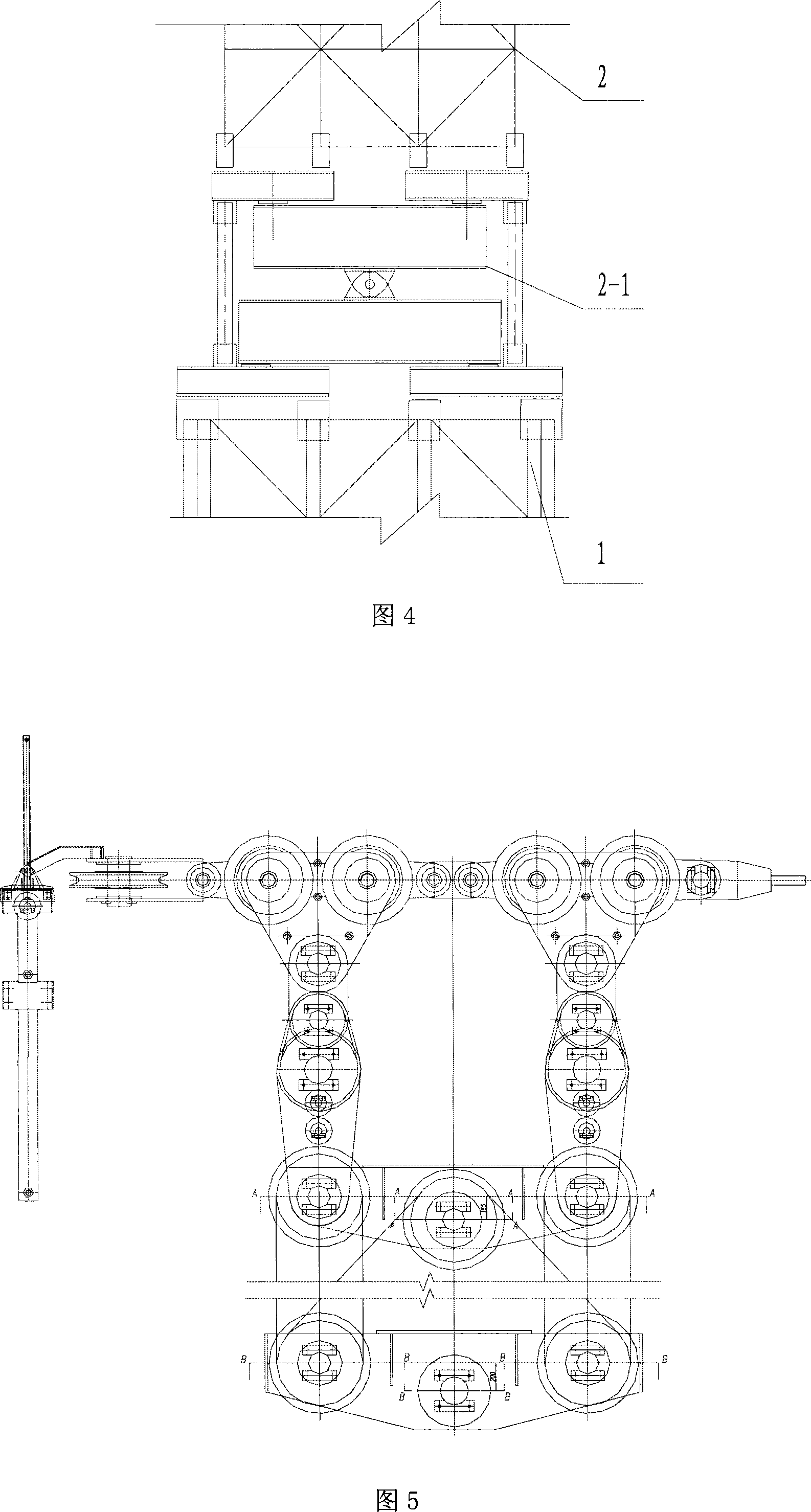

[0023] Referring to Fig. 1, 2, 3, this cable crane is made up of buckle cable tower 1, cable tower 2, main cable and hoisting traction system 3, anchoring system 4, electromechanical system 5, cable wind system 6.

[0024] Take the 420t cable crane of Caiyuanba Yangtze River Bridge in Chongqing as an example below to describe the present invention:

[0025] 1. Cable tower

[0026] The cable tower 2 and the buckle tower 1 are built together, the bottom of the buckle tower 1 is consolidated, and the cable crane tower 2 is hinged on the top of the buckle tower 1 to reduce the unbalance level when the cable crane is working The influence of force on the buckle tower 1. The 1 column of the buckle cable tower is assembled by double-column and three-column universal rods inside and outside. The 2 columns of the cable crane are assembled from single-column universal rods. The cable tower frame 2 is temporarily consolidated during assembly, and after the cable tower frame 2 is assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com