Construction method and construction system for on-site cold regeneration

A construction method and cold recycling technology, which can be used in on-site coagulation pavement, roads, road repair and other directions, can solve the problems of difficult control of construction quality, low construction efficiency, long maintenance time, etc., and improve the construction efficiency of cold recycling. , construction quality control, the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Step 1, foaming condition experiment. That is, the indoor test determines the optimal foaming temperature and water consumption of foamed asphalt, and the indoor foamed asphalt foaming test machine is preferably Wirtgen indoor foaming equipment WLB10;

[0065] In order to meet the foamed asphalt expansion rate and half-life required for construction, set the asphalt dosage and foaming water consumption of the regenerator, and use the test nozzle on the regenerator to conduct a foaming test before construction to check the foaming effect. The foamed asphalt is preferably 70 , No. 90 base asphalt.

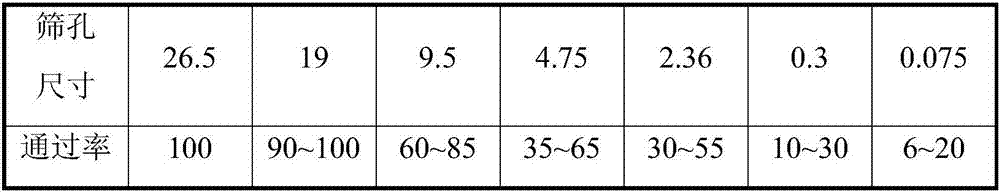

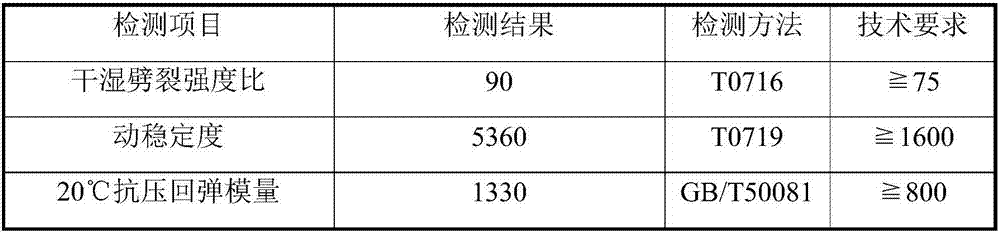

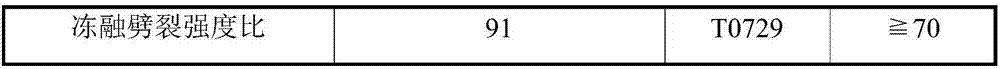

[0066] Step 2: The pre-mixed active filler and crushed stone are evenly spread by the spreader according to the computer control system, and the cold recycling machine pushes the asphalt tanker and the water tanker to start operation through the push rod. Sprinkle ready-mixed active filler and gravel on the road surface to be cooled and regenerated by using a pre-mixed materi...

Embodiment 2

[0072] Step 1, foaming condition experiment. That is, the indoor test determines the optimal foaming temperature and water consumption of foamed asphalt, and the indoor foamed asphalt foaming test machine is preferably Wirtgen indoor foaming equipment WLB10;

[0073] In order to meet the foamed asphalt expansion rate and half-life required for construction, set the asphalt dosage and foaming water consumption of the regenerator, and use the test nozzle on the regenerator to conduct a foaming test before construction to check the foaming effect. The foamed asphalt is preferably 70 , No. 90 base asphalt.

[0074] Step 2: The pre-mixed active filler is evenly spread by the spreading vehicle according to the computer control system, and the cold recycling machine pushes the asphalt tanker and the water tanker to start operation through the pushing rod. Sprinkle the pre-mixed active filler on the pavement to be cooled and regenerated by using the pre-mixed material sprayer. The r...

Embodiment 3

[0080] Step 1, foaming condition experiment. That is, the indoor test determines the optimal foaming temperature and water consumption of foamed asphalt, and the indoor foamed asphalt foaming test machine is preferably Wirtgen indoor foaming equipment WLB10;

[0081] In order to meet the foamed asphalt expansion rate and half-life required for construction, set the asphalt dosage and foaming water consumption of the regenerator, and use the test nozzle on the regenerator to conduct a foaming test before construction to check the foaming effect. The foamed asphalt is preferably 70 , No. 90 base asphalt.

[0082] Step 2: The pre-mixed active filler is evenly spread by the spreading vehicle according to the computer control system, and the cold recycling machine pushes the asphalt tanker and the water tanker to start operation through the pushing rod. Sprinkle the pre-mixed active filler on the pavement to be cooled and regenerated by using the pre-mixed material sprayer. The r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com