Device and method of measuring working performance of pervious concrete

A technology of permeable concrete and work performance, applied in the direction of material inspection products, etc., can solve the problems of less permeable concrete and impracticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

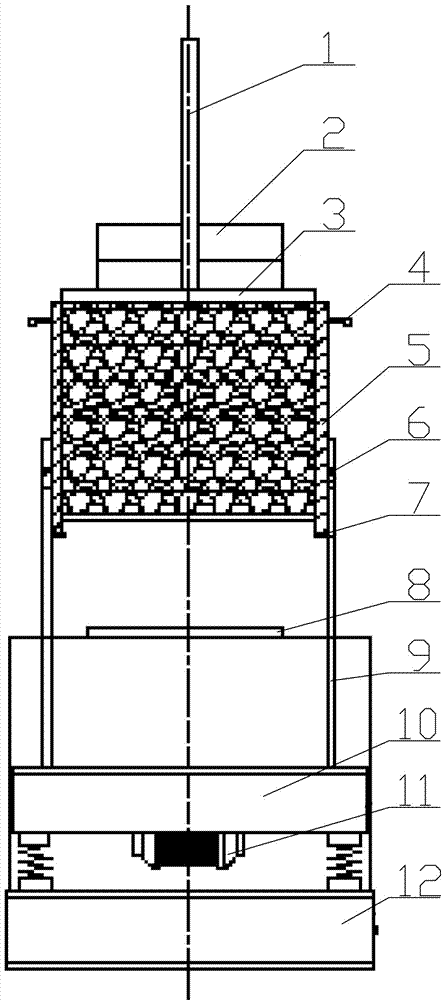

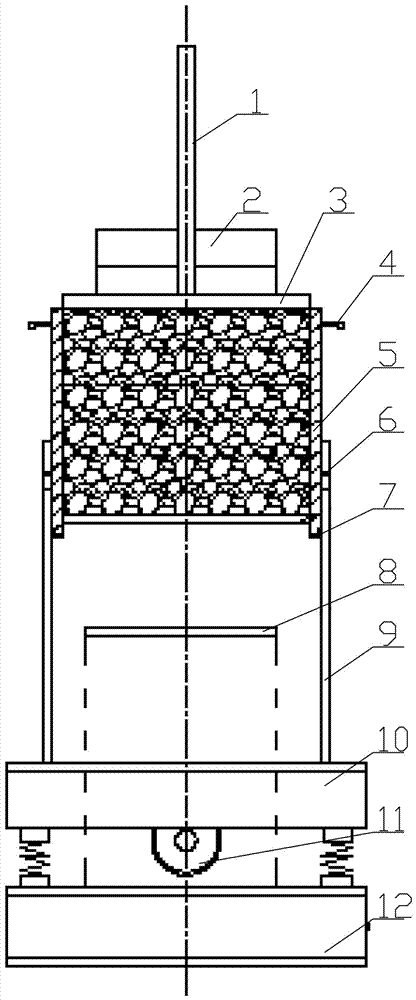

[0037] like Figure 1-4 Shown is a device for measuring the performance of permeable concrete, which consists of upper and lower parts that can be disassembled and assembled. Wherein, the upper part includes a test detection barrel 5, the test detection barrel 5 is detachably installed on the top of the fixed frame 9, the top of the test detection barrel 5 is provided with a transparent disc 3, and the transparent disc 3 A counterweight device is installed on the top. Described lower part comprises base 12, and vibrating table 10 is installed on described base 12, and vibrating motor 11 is installed in the bottom of vibrating table 10, and mirror 8 is arranged directly below test detection bucket 5, and described mirror 8 Fixedly installed on the base 12. By adopting the above-mentioned device, it can be used for subsequent testing of the working performance of permeable concrete.

[0038] Further, the fixed frame 9 is welded and assembled by a vertical bar and a horizontal...

Embodiment 2

[0047] The method of using any one of the devices for measuring the performance of permeable concrete, it may further comprise the steps:

[0048] Step1: Sample preparation, put the admixture in three layers and put it into the test detection barrel 5. After the admixture in each layer is tamped, it is about 1 / 3 of the height of the cylinder. Insert a tamping rod evenly on the section of each layer for 25-35 Second, when inserting and pounding the second layer of suction top layer, it should be inserted through this layer and make the tamping rod just enter the lower layer, after the top layer is compacted, just scrape flat along the upper mouth of the test detection barrel 5 with a flat plate;

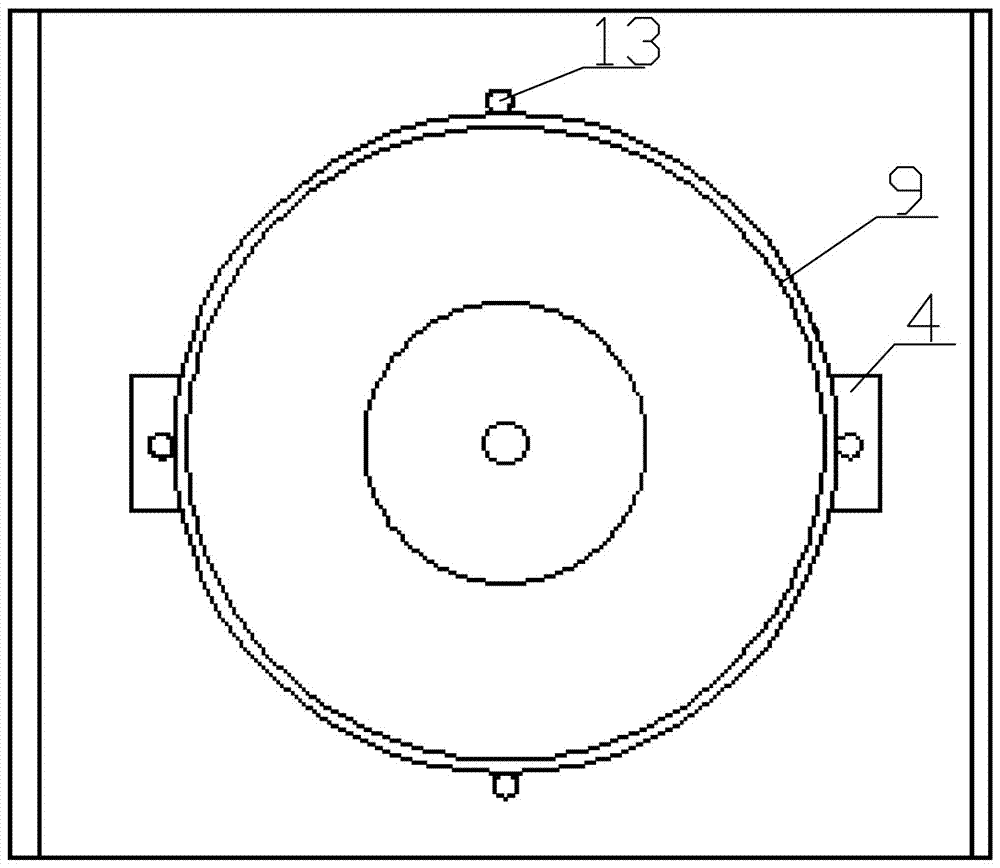

[0049] Step2: Fix the test detection barrel 5, insert the 4 vertical steel pipes of the fixing frame 9 into the cylindrical holes 13 on the test detection barrel, place the bottom of the test detection barrel 5 on the cross bar, and fix the test detection barrel with nuts;

[0050]Ste...

Embodiment 3

[0056] A method for measuring the performance of permeable concrete, the method comprising the following steps:

[0057] Sample preparation: prepare the mixture according to the designed mixing ratio, stir evenly, carry out the test according to the cooking time of 30min, 60min, 90min, and 120min respectively, and put it into the test detection barrel in three layers. It is 1 / 3 of the height of the cylinder. Insert and tamp 25 times evenly with a tamping stick on the cross section of each layer. When inserting and tamping the second layer of suction top layer, it should be inserted through this layer and make the tamping stick just enter the lower layer. The top layer is tamped. Use a flat plate to scrape flat along the top of the test barrel.

[0058] Fix the test barrel: insert the 4 steel pipes of the fixing frame into the small cylindrical holes on the test barrel, place the bottom of the test barrel on the horizontal connecting rod, and fix the test barrel with nuts.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com