External wallboard block of industrial building and mounting method thereof

A technology for exterior wall decoration and exterior wall, which is applied in the directions of buildings, building components, building structures, etc., can solve the problems of slow construction, easy breakage, uneven quality, etc., to prevent construction quality problems and improve thermal insulation. effect, the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

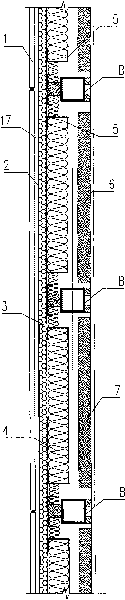

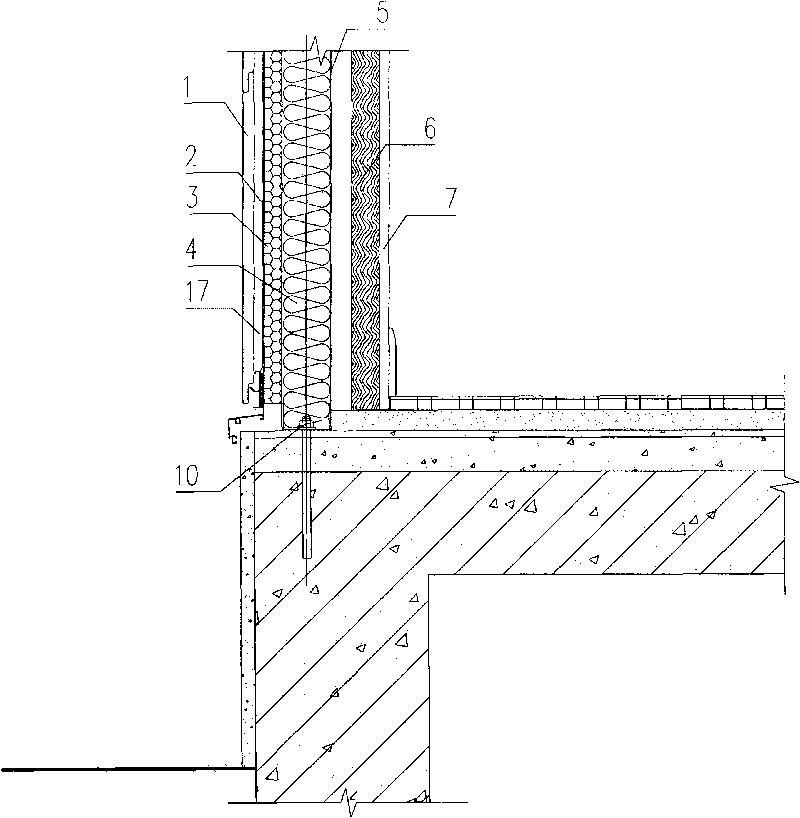

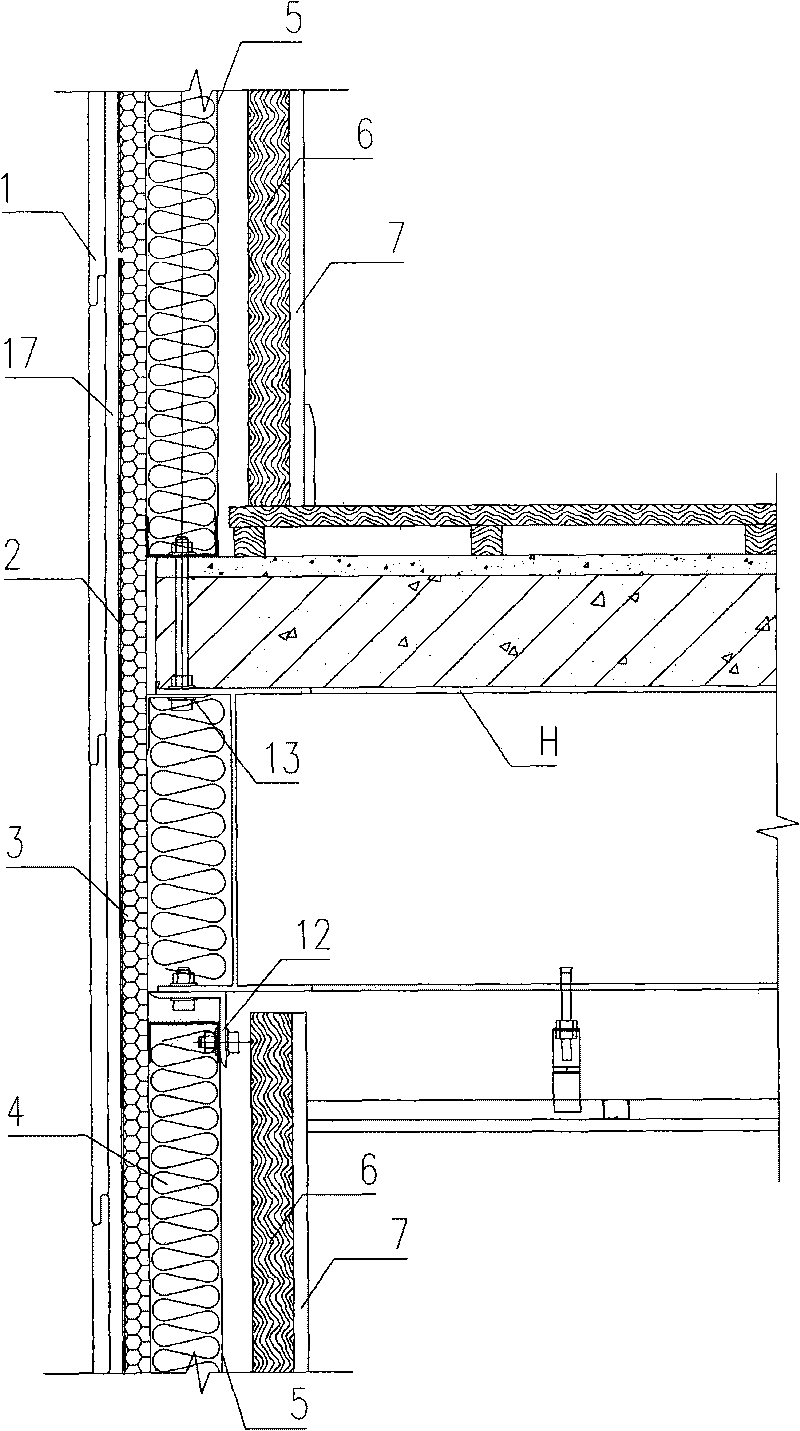

[0023] Such as figure 1 As shown, an exterior wall panel of an industrialized building in the present invention includes a wall panel frame block 5 embedded with a thermal insulation material 4, and the side of the wall panel frame block 5 facing the outdoor is sequentially fixed with a block thermal insulation material 3, a moisture-permeable Waterproof paper 2, air layer 17, exterior wall decoration hanging board 1; wall panel frame block 5 faces the indoor side, and wooden keel 6 and interior wall decoration board 7 are fixed in sequence.

[0024] Such as Figure 4 , Figure 5 As shown, the wall panel frame block 5 is a rectangular frame made of metal components, and is composed of longitudinal frame bars 51 and transverse frame bars 52 connected together at certain intervals. At least two hoisting holes 14 are set on the uppermost transverse frame bar 52 of the wallboard frame block 5, and several hole positions-15 are set on the lowermost transverse frame bar 52 lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com