Segmental lifting method for impeller of high-power wind driven generator

A technology for wind turbines and segmented hoisting, which is applied to wind turbines, wind power generation, and wind turbines in the same direction as the wind. It can solve problems such as difficult control of the installation process, large impeller frontal area, and limited assembly site. , to achieve the effect of controlling construction quality, reducing construction land area, and preventing soil erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

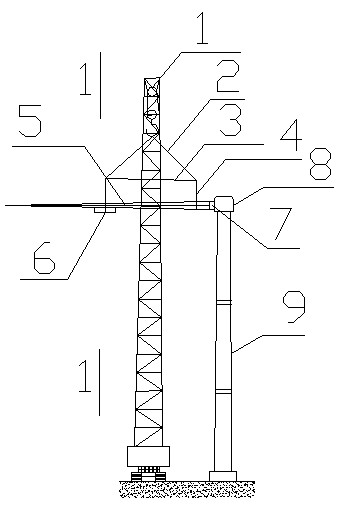

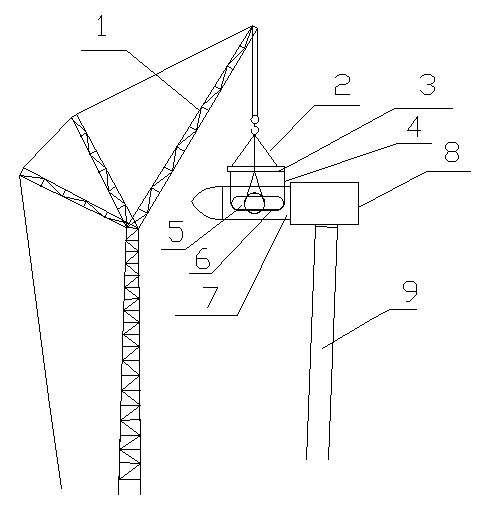

[0023] In order to further describe the present invention, the method for hoisting the impeller of the high-power wind generator in the present invention will be further described below in conjunction with the drawings and embodiments.

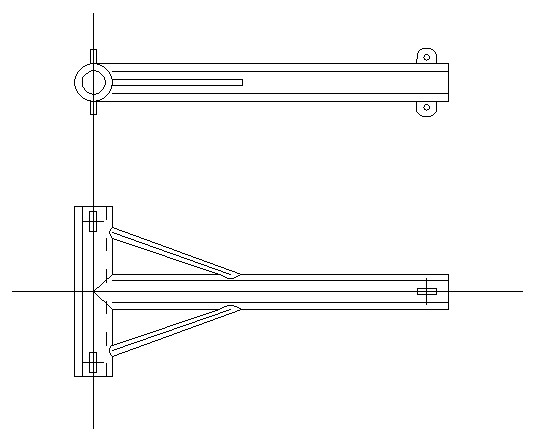

[0024] As shown in the figure, the method for hoisting the impeller of the high-power wind power generator in pieces is to use the crane ( 1) hoist the wheel hub (7) and three single blades (5) in place with the machine tools and wire ropes (2), and connect them into one body in the air.

[0025] The fragmented hoisting method of the high-power wind turbine impeller is carried out according to the following steps:

[0026] The first step is to assemble the hub on the ground. The wheel hub (7) shell is divided into two sections and enters the site, which is assembled on site and hoisted as a whole. The ground assembly site shall be compacted, flattened and supported by road logs. The two connecting bolts should be tightened one by one.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com