Construction method of large-span post-tensioned prestressed longitudinal and transverse frame beams

A construction method and prestressing technology, which is applied in construction, building structure, and processing of building materials, can solve problems such as difficulty in ensuring construction quality, cracks in surrounding cast-in-place slabs, and long construction periods, so as to reduce material consumption, The effect of increasing the headroom of the house and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

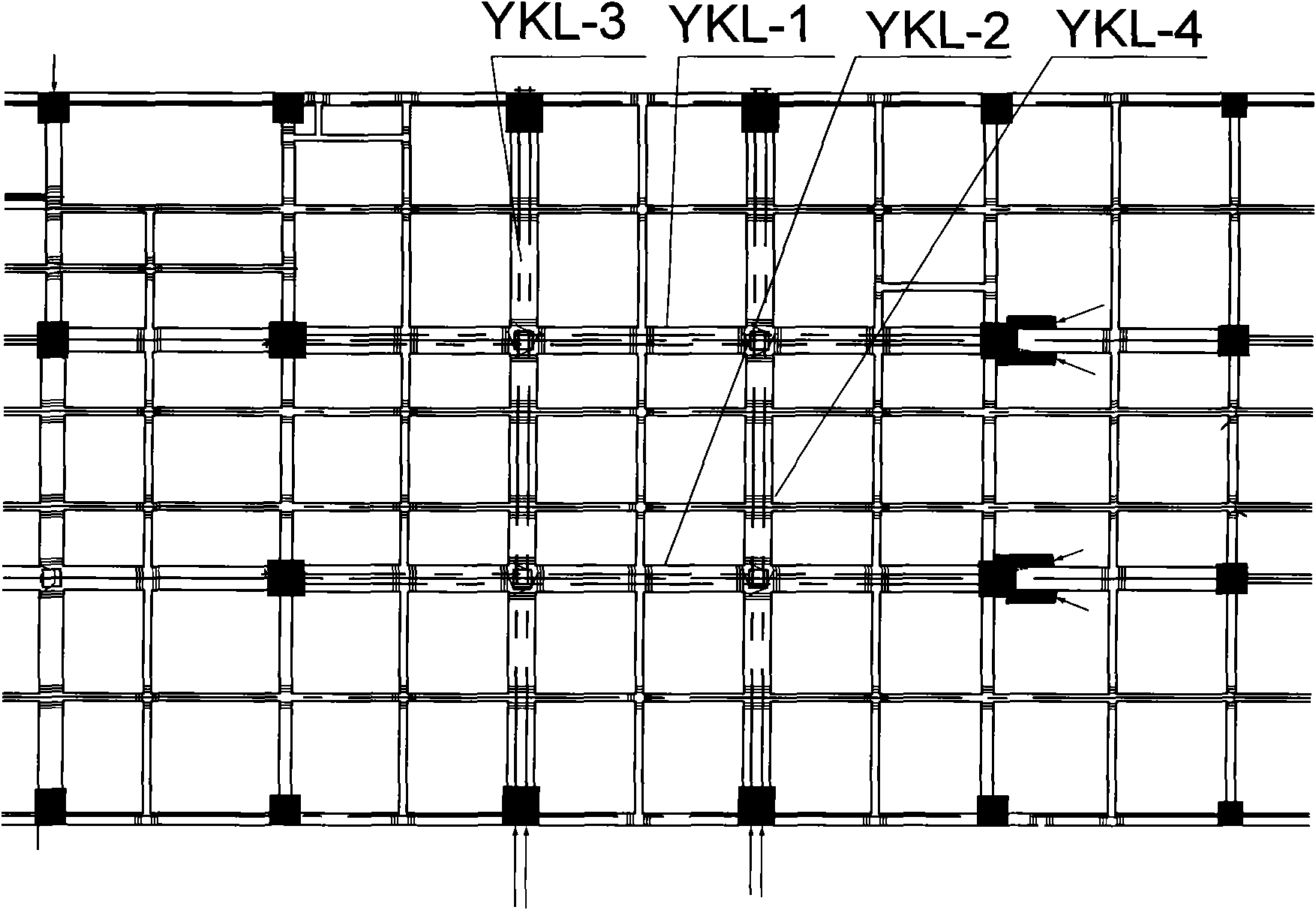

[0030] Such as figure 1 Shown is a schematic diagram of the prestressed frame beam structure of a station, the prestressed frame beam includes the first prestressed frame beam YKL-1, the second prestressed frame beam YKL-2, and the third prestressed frame beam YKL-3 , the fourth prestressed frame beam YKL-4, the construction steps are as follows:

[0031] 1. Inspection of steel strand anchors: After the steel strands and anchors enter the site, they should be inspected.

[0032] 2. Steel strand cutting

[0033] Calculate the blanking length according to the design drawings, the formula for the blanking length (L) is as follows:

[0034] L=l+2h+l1+l2 In the formula: l----the length of the channel curve, h----the thickness of the anchor plate, l1----the working length of the jack at the tension end, l2----fixed The length of the exposed anchorage of the steel strand at the end, if it is tensioned at both ends, it is the working length of the jack at the other tensioned end. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com