Full-prefabricated floor special for fabricated steel structure

A steel structure, prefabricated technology, applied in the direction of floor slabs, building components, building structures, etc., can solve the problems of affecting construction progress, high demolition costs, labor-intensive and labor-intensive, etc., to reduce on-site operations, material costs, and overall structural strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

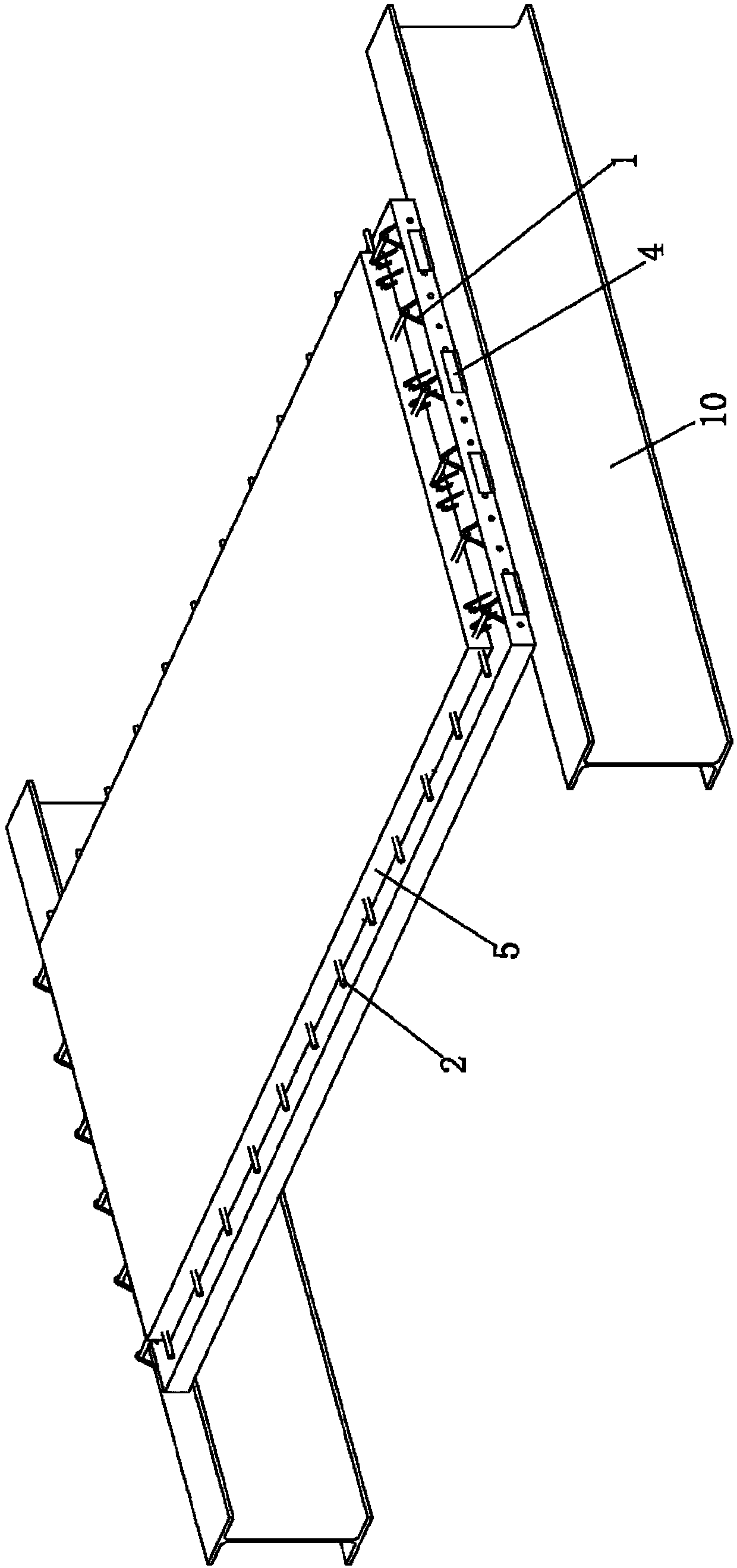

[0024] Please refer to the attached figure 1 to attach Figure 5 As shown, the present invention is a special prefabricated floor slab for a prefabricated steel structure, which is arranged on a steel beam 10 (or other steel structure system), and it is composed of a steel bar truss 1, gluten bars 2, bottom bars 3, embedded parts 4 and The prefabricated concrete layer 5 is composed of several parts. Wherein, the steel bar trusses 1 , gluten bars 2 , bottom bars 3 , and embedded parts 4 are pre-embedded in the precast concrete layer 5 respectively.

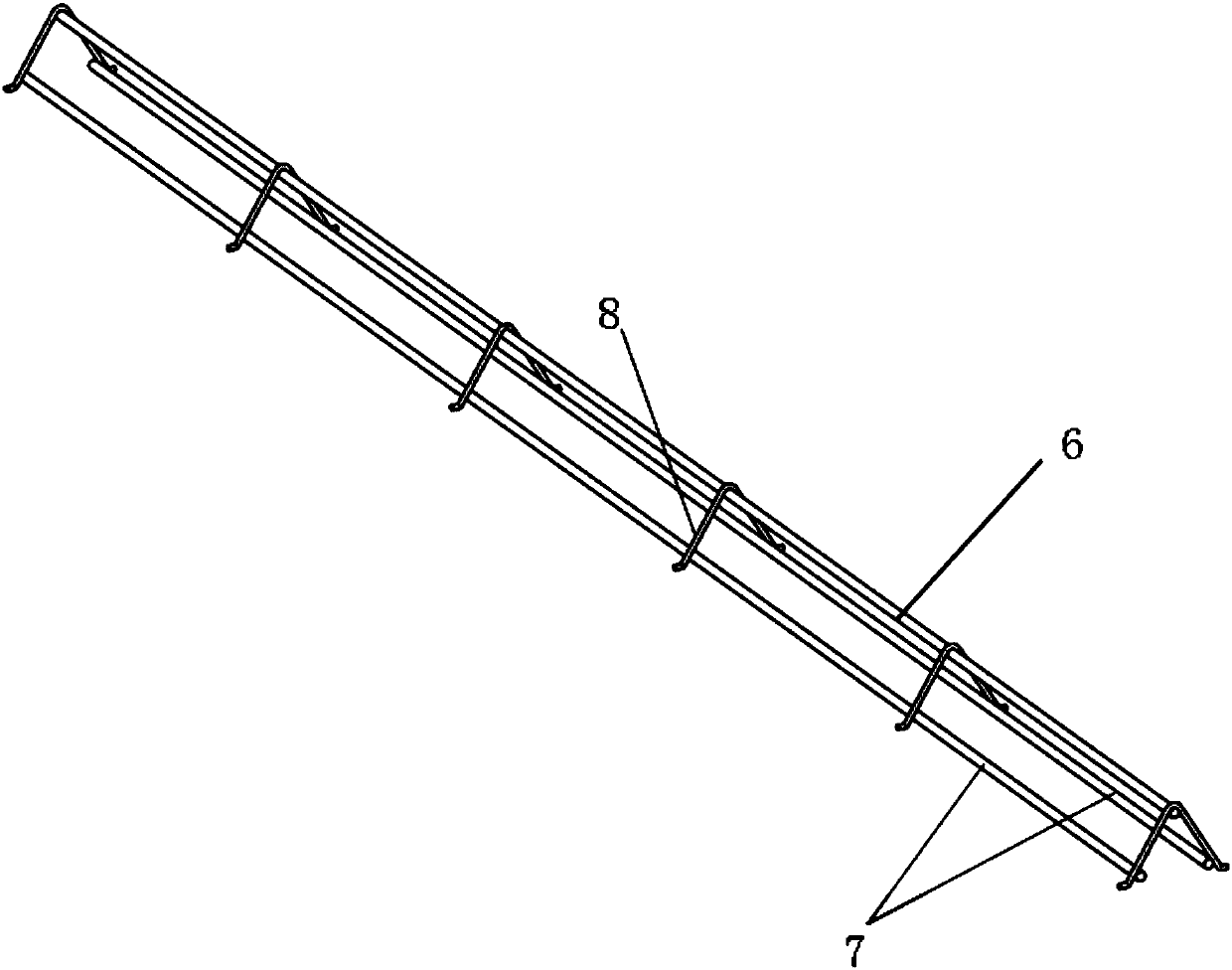

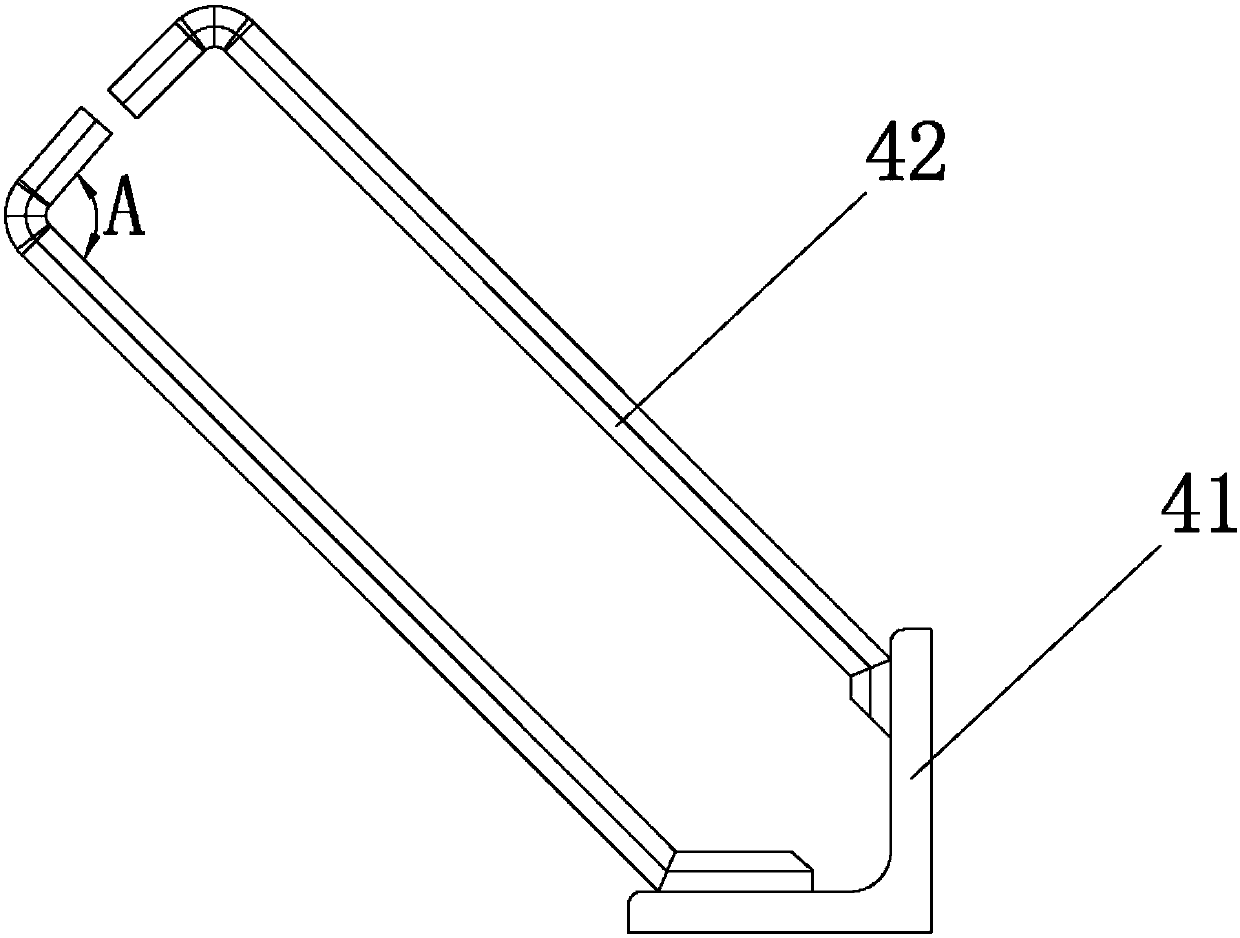

[0025] Wherein, the steel bar truss 1 is not only a part of reinforcement in the prefabricated floor slab, but also plays a supporting role. The upper chord steel bars 6 and the lower chord steel bars 7 are arranged parallel to each other and arranged in an isosceles triangle; The erecting ribs 8 are arranged at equal intervals and are in an inverted V shape, which can be bent steel bars, or common web bars and other forms of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com