Outsourcing multi-cavity steel plate concrete composite shear wall and its construction method

A steel plate concrete and composite shear wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problem of unsatisfactory ductility and other problems, achieve a wide range of applications and development space, good performance, and save materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

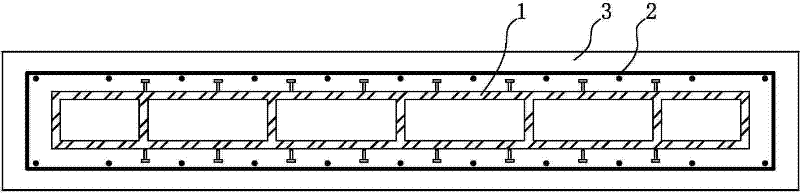

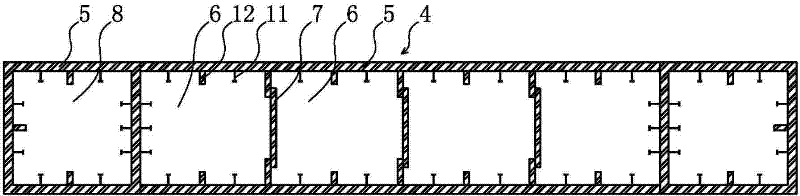

[0028] Such as figure 2 As shown, in the outsourcing multi-cavity steel plate concrete composite shear wall of the present invention, the outer periphery of the wall body 4 is surrounded by steel plates 5, and the interior of the wall body 4 is divided into several interconnected cavities 6. Fill with concrete. Both ends of the wall body 4 are respectively provided with concealed column cavities 8 surrounded by steel plates, and the concealed column cavities are filled with concrete, which is not shown in the figure. The inner side of the steel plate 5 is provided with several studs 11, the studs are perpendicular to the steel plate, the studs can increase the bonding force between the concrete and the steel plate and prevent the steel plate from buckling under pressure. The inner side of the steel plate is also provided with several stiffening ribs 12, the stiffening ribs 12 are perpendicular to the steel plate, and the stiffening ribs can prevent the steel plate from buckl...

Embodiment 2

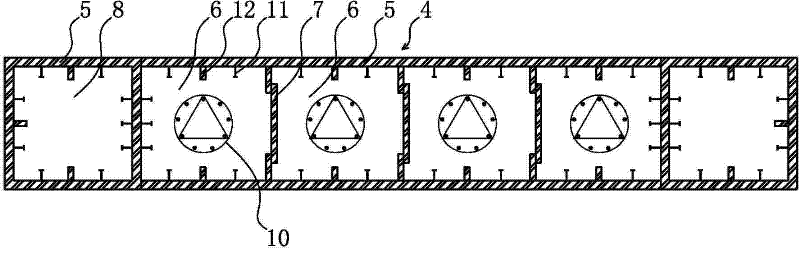

[0031] Such as image 3 As shown, the difference between this embodiment and the first embodiment is that each cavity in the wall is provided with a reinforcement cage 10 respectively. Setting the reinforcement cage is mainly applicable to the situation that the wall thickness is relatively large, and profiled steel or reinforcement can also be placed in the concealed column cavity 8 according to the force requirements.

Embodiment 3

[0033] Such as Figure 4 As shown, the difference between this embodiment and the first embodiment is that the wall is provided with a steel mesh 9, and the steel mesh 9 is distributed in each cavity 6 and connects each cavity. Setting the reinforcement mesh 9 is mainly applicable to the situation where the wall thickness is relatively large, and profiled steel or reinforcing bars can also be placed in the concealed column cavity 8 according to the force requirements.

[0034] The present invention imposes constraints on the concrete in the shear walls. Among them, square concrete-filled steel tube columns are formed in the hidden column cavity at the end; multiple continuous and semi-closed cavities are formed on the wall body by using steel plates on both sides and opposite slabs, which also form constraints on the concrete in them. Thus, the mechanical properties of high-strength concrete, especially the deformation capacity, can be effectively improved.

[0035] The wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com