Liftable hydraulic climbing template and construction method thereof

A climbing formwork and hydraulic lifting technology, applied in formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of large bearing capacity and low steel consumption of support rods, and achieve large bearing capacity. , The effect of small steel consumption and safe operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

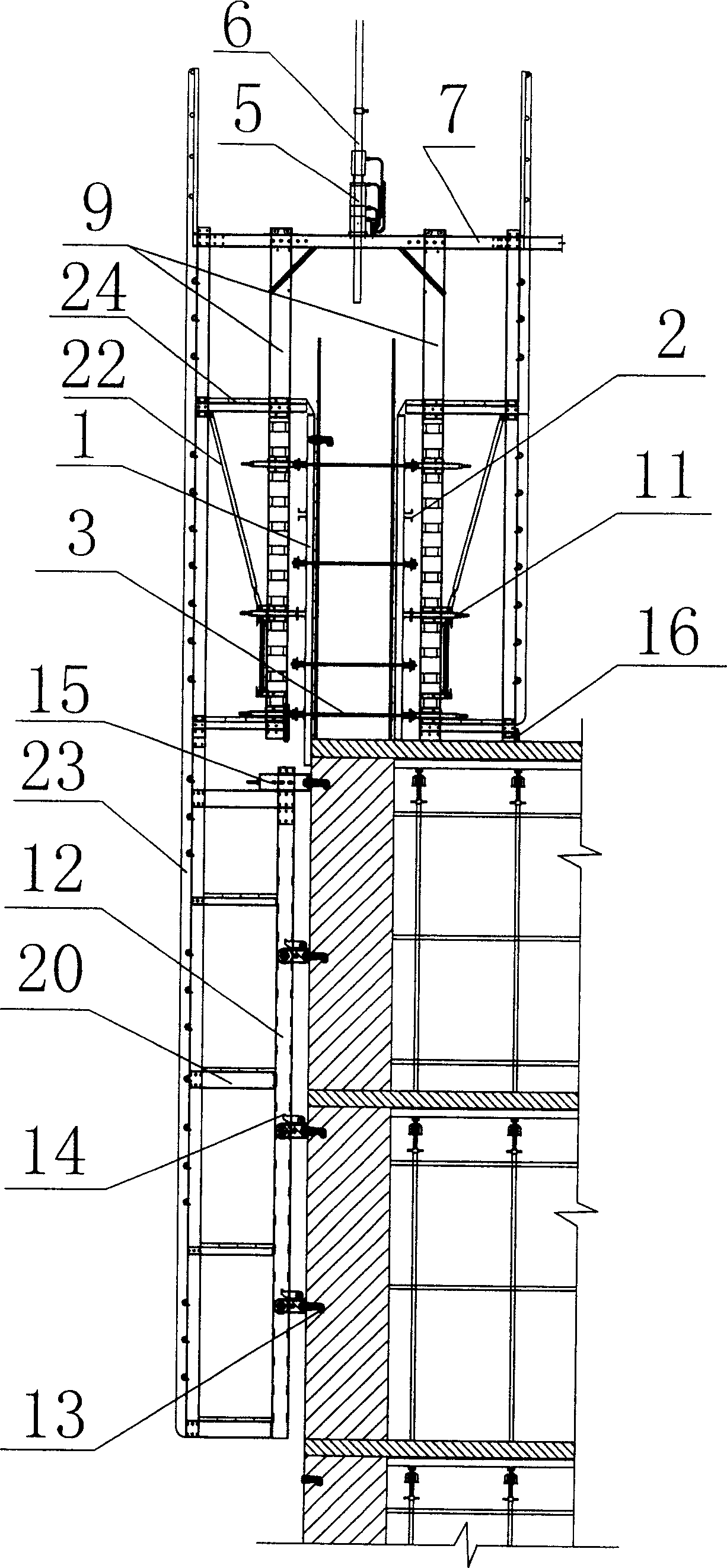

[0075] Embodiment one sees Figure 1-6 , the steps of using hydraulic climbing formwork to construct the wall:

[0076] (1), see figure 1 , Bind the steel bars at the initial layer, install the formwork system and the hydraulic lifting system, and the formwork system and the operating platform system are connected into a whole by the hydraulic lifting system.

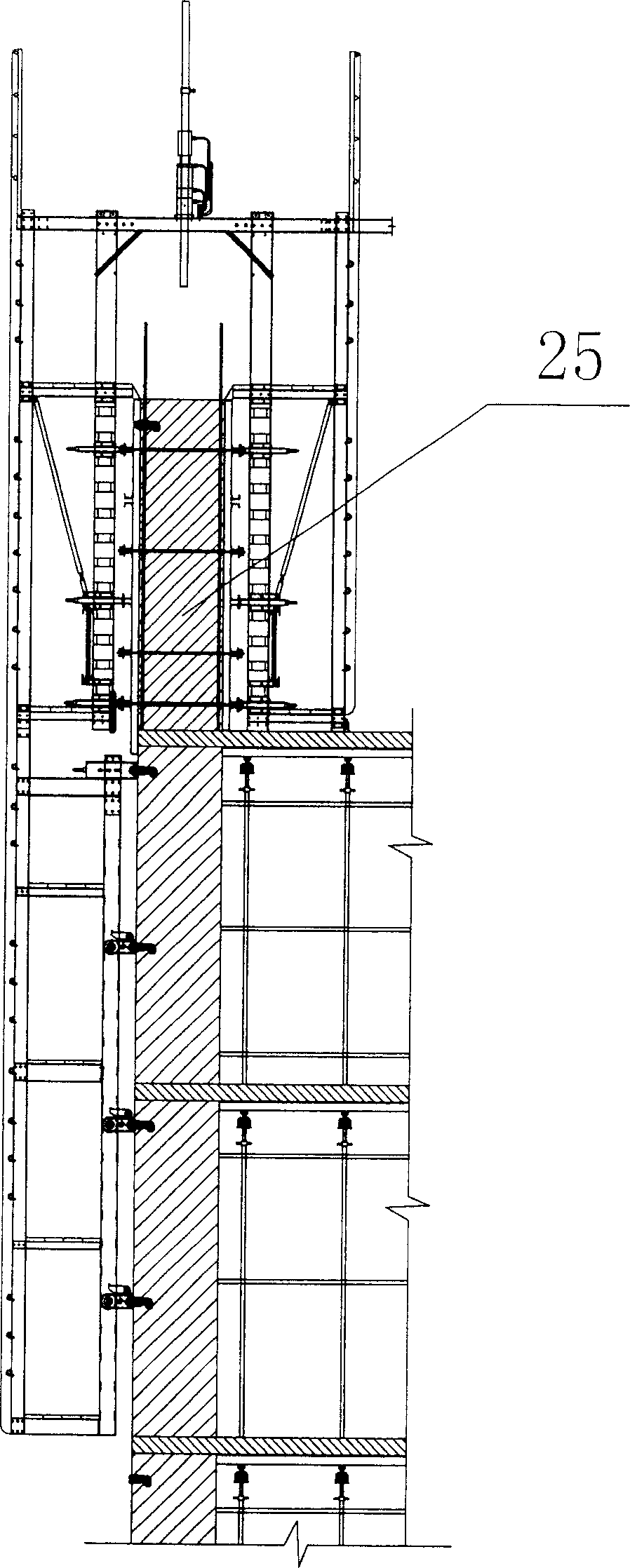

[0077] (2), see figure 2 , Concrete 25 is poured in the formwork according to conventional construction methods.

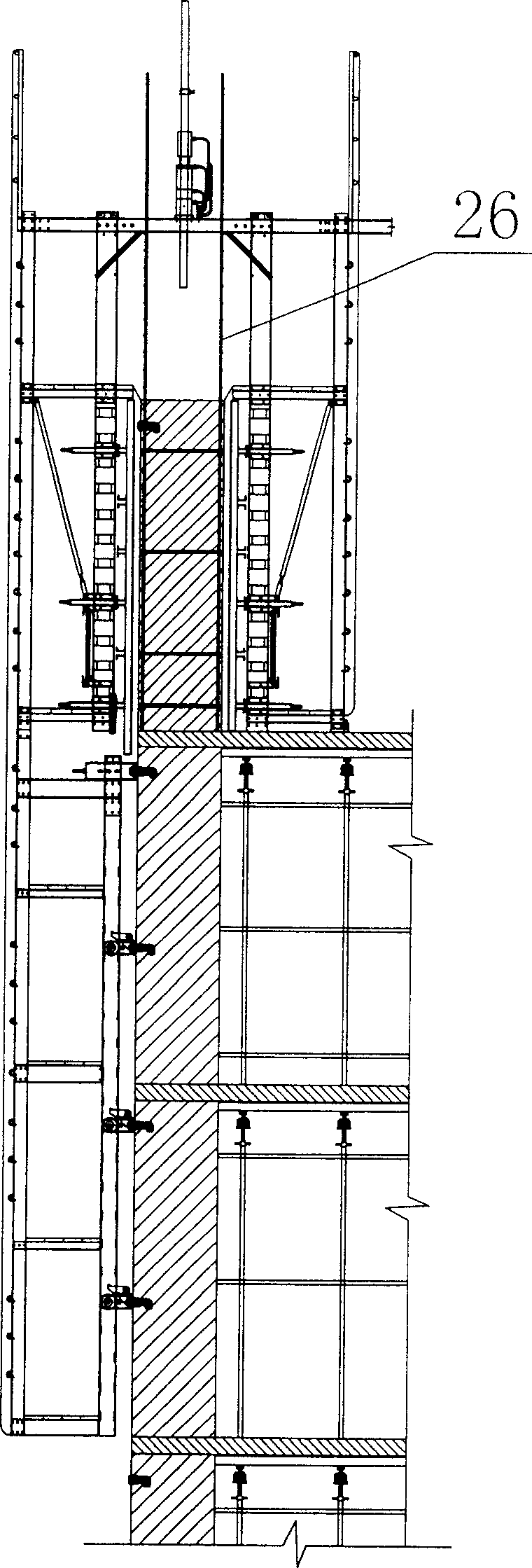

[0078] (3), see image 3 , Concrete curing; During this period, the upper part of the reinforcement 26 is bound.

[0079] (4) When the concrete reaches the demoulding strength, the pull bolts of the formwork system are removed, and the formwork is retreated 80mm from the concrete by the stripper, see Figure 7 , 8 .

[0080] (5), see Figure 4 , the support rod 6 descends to the concrete top surface or the top surface backing plate.

[0081] (6) Fix the support rod to the concrete top surface, see...

Embodiment 2

[0097] Embodiment two see Figure 12 , the steps of using hydraulic climbing formwork to construct the column:

[0098] (1), see figure 1 , Bind the steel bars at the initial layer, install the formwork system and the hydraulic lifting system, and the formwork system and the operating platform system are connected into a whole by the hydraulic lifting system.

[0099] (2), see figure 2 , Concrete 25 is poured in the formwork according to conventional construction methods.

[0100] (3), see image 3 , Concrete curing; During this period, the upper part of the reinforcement 26 is bound.

[0101] (4) When the concrete reaches the demoulding strength, the pull bolts of the formwork system are removed, and the formwork is retreated 80mm from the concrete by the stripper, see Figure 7 , 8 .

[0102] (5), see Figure 4 , the support rod 6 descends to the concrete top surface.

[0103] (6) Use a semi-conical cast steel wedge to fix the supporting rod and the concrete top surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com