Organic soilless lawn blanket and rapid producing method thereof

A technology of soilless lawn and production method, which is applied in the direction of soilless cultivation, botany equipment and method, agricultural gas emission reduction, etc., and can solve the problems of increasing the production cost of soilless lawn blanket, new pollution sources of soil, and too expensive price, etc. Achieve the effect of improving overall benefit and market competitiveness, simple process and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

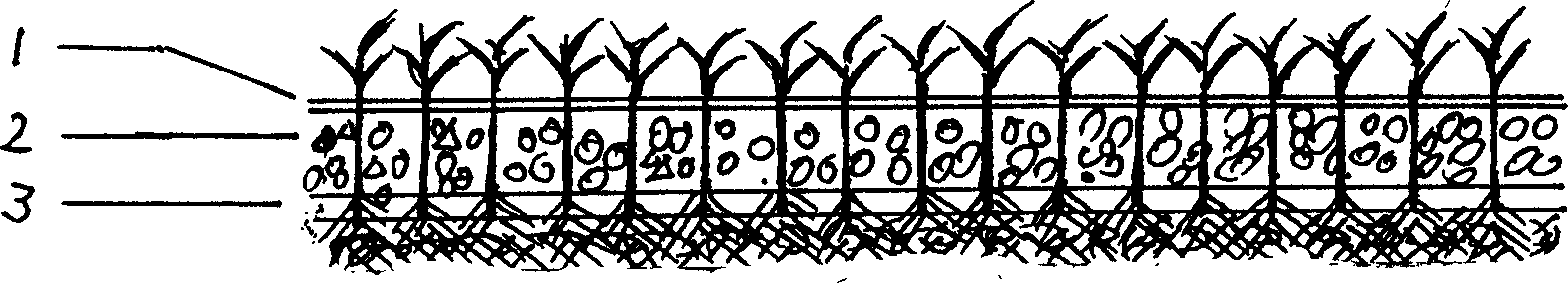

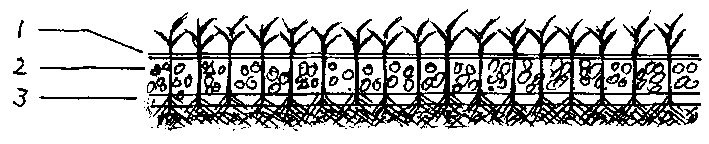

[0018] refer to figure 1 , the organic soilless lawn blanket of the present invention is made up of lawn grass 2 (comprising slow-release compound fertilizer, water-retaining agent, bactericide, dwarfing agent etc.), lower layer non-woven fabric 3, upper layer non-woven fabric 1. The non-woven fabric is made of hemp fiber waste. The thickness of the lower non-woven fabric 3 is about 0.3 cm, and the weight is 70-80 grams per square meter. The thickness of the upper non-woven fabric 1 is less than 0.1 cm, and the weight is 20-80 grams per square meter. 30 grams.

[0019] In this example, the zoysia seed sowing method is used to produce a standard greenhouse (30 meters long x 6 meters wide) organic soilless lawn blanket, and the operations are as follows:

[0020] 1) Preparation of simple greenhouse and ground isolation layer: steel pipe structure is used, covered with plastic film in spring, autumn and winter, and sunshade film in summer, and the ground in the shed is covered w...

Embodiment 2

[0025] In this example, the stems, rhizomes and stolons of bentgrass are used as vegetative propagules for production.

[0026] After collecting the vegetative propagules of bentgrass stolonifers, process them into 3 to 4 cm long stem segments with 2 to 4 bud nodes, prepare the stem segments at a seeding rate of 100 to 150 grams per square meter, and soak them in clean water 12 to 24 hours, and prepare water-retaining and heat-insulating materials (soaked) such as sacks, straw bags or non-woven fabrics. First, lay and fill a number of bottom layers, and then spread the soaked stems on top of them. The thickness is generally 10 About one centimeter, then cover with some cover, and place it at 20-25°C, humidity 70-80% to accelerate germination, uncover the cover every day, turn over the stems, and drench them once until the stems germinate and turn white. Carry out sowing and management by the same steps and materials of embodiment 1, until becoming flat, going out of garden, ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com