Metallic face sandwiched composite board and assembled composite wall panel

A sandwich composite panel and composite wall panel technology, which is applied in the direction of building components, buildings, building structures, etc., can solve the problem that there is no suitable horizontal typesetting metal surface polystyrene sandwich composite panel, which cannot meet the requirements of novel and diverse architectural shapes. requirements, no problems such as horizontal typesetting, to achieve the effect of increasing visual beauty, not easy to confuse, and preventing slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

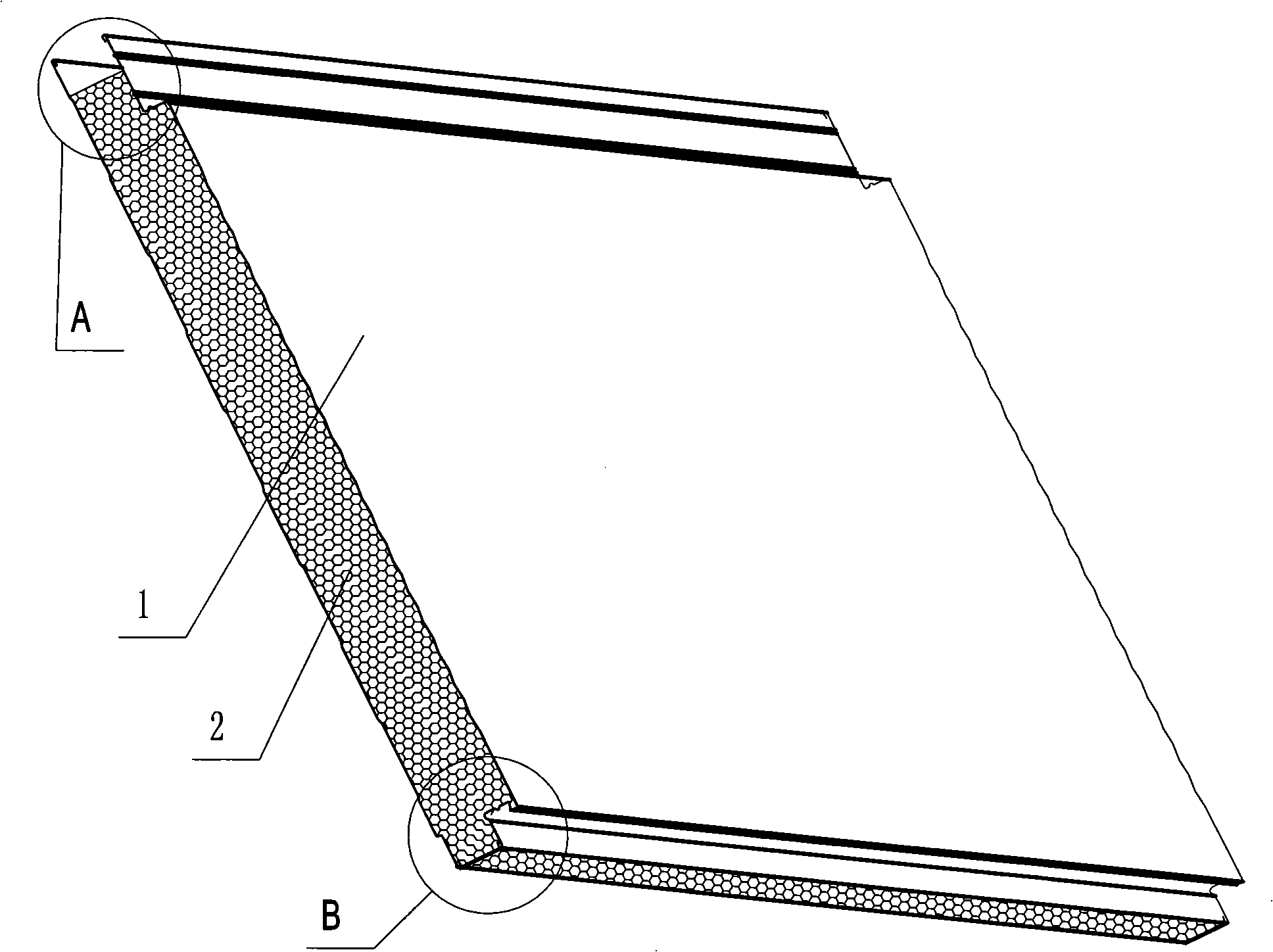

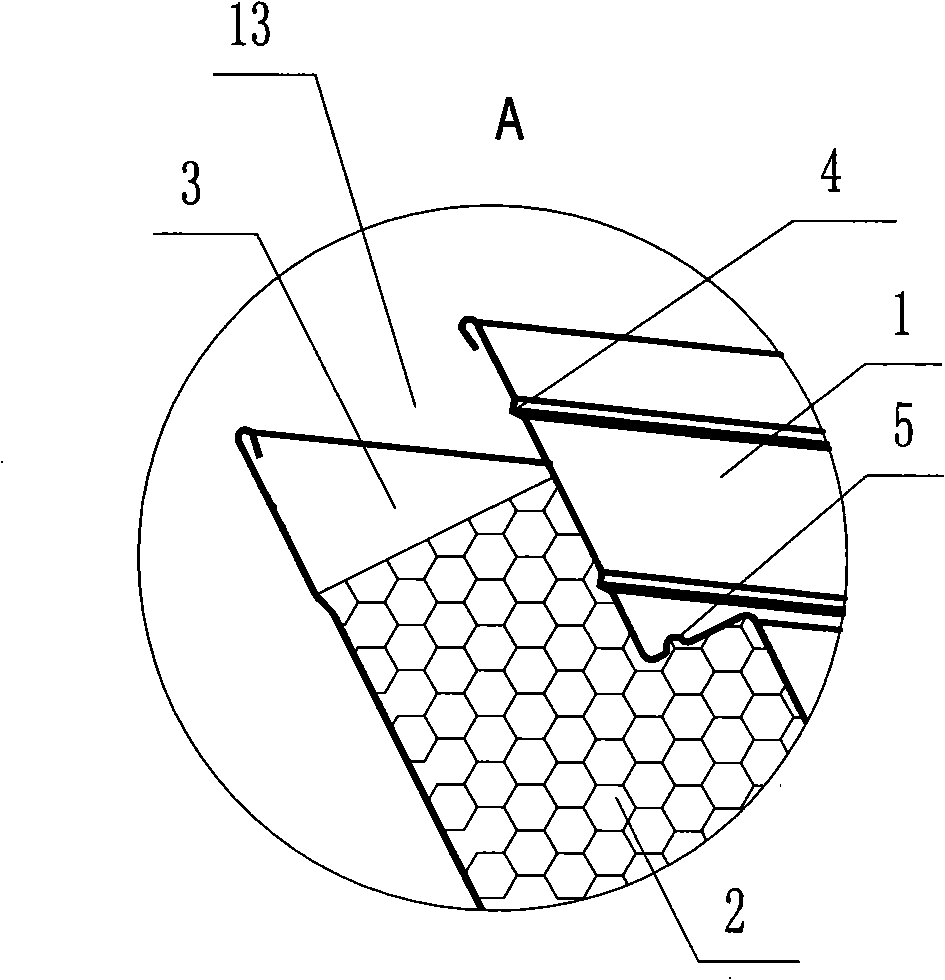

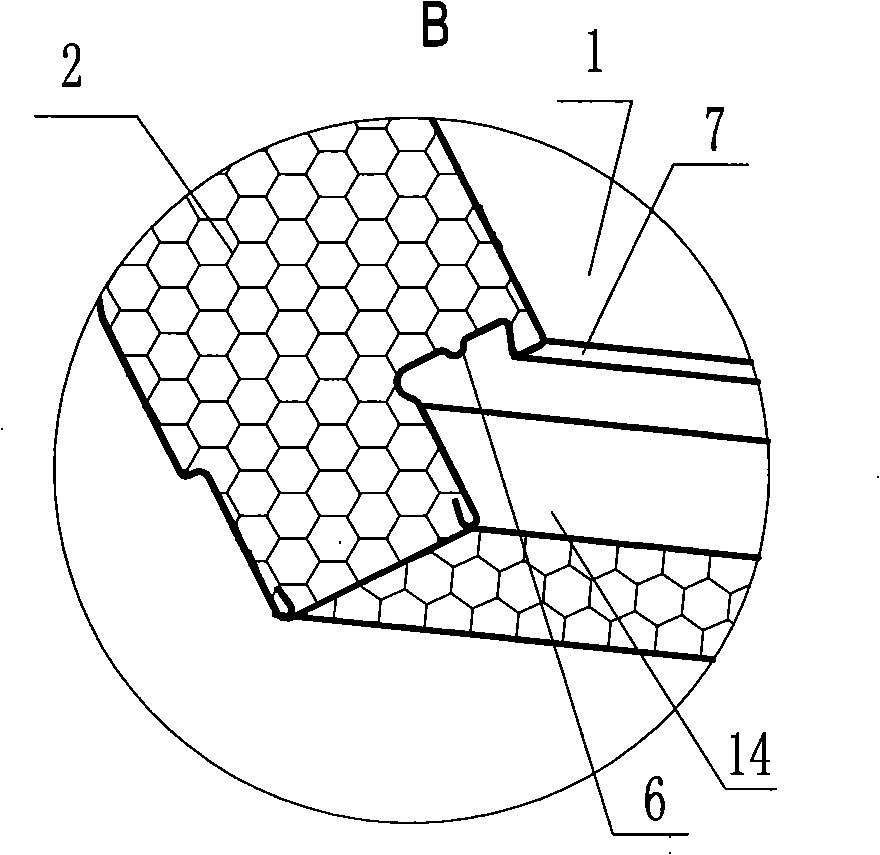

[0023] figure 1 , figure 2 , image 3 The metal-face sandwich composite panel shown includes an outer panel 1, an inner panel 3 and a sandwich layer 2 between the two panels. The two opposite splicing ends on the composite panel are the insertion slot end A and the insertion head end respectively. B. At the end of the insertion groove, the end of the outer panel 1 is bent inward to form a fixed platform with a height lower than the composite panel surface, the end wall of the outer panel 1 and the end wall of the inner panel 3 and the sandwich layer 2 The end faces of the two together form an insertion groove 13, and a nail groove 4 parallel to the edge of the composite board is provided on the board surface of the fixed platform; at the insertion head end, the end of the outer panel is bent to a height lower than that of the composite board. The top of the surface, the end of the outer panel, the end of the inner panel and the end surface of the sandwich layer together con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com