Flat-pipe microchannel aluminum radiator

A technology of micro-channel and heat sink, which is applied in the direction of cooling/ventilation/heating transformation, etc. It can solve the problems of poor heat dissipation effect of high-power variable frequency fan drive module, affecting the normal operation of air conditioners, and unsatisfactory heat dissipation effect, etc., to achieve good heat dissipation effect , Low production cost, and the effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

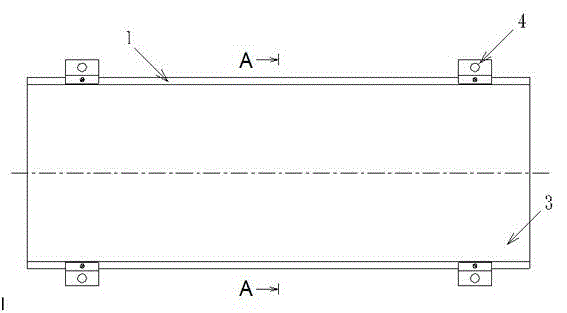

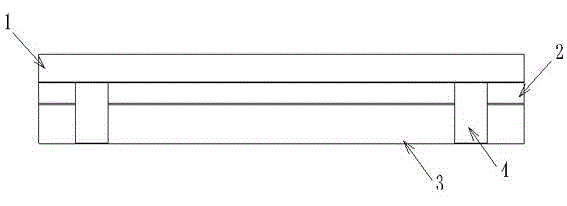

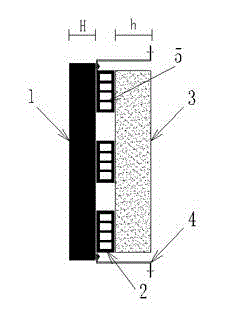

[0026] Such as Figure 1-3 As shown, the flat tube microchannel aluminum radiator of this embodiment includes an aluminum plate 1 and an insulating layer 3 fixed on the air conditioner electrical box (not shown in the figure), the material of the insulating layer 3 is rubber, and the aluminum plate 1 and the insulating layer Two flat tube microchannel heat exchange tubes 2 are arranged between layers 3, the flat tube microchannel heat exchange tube 2 is an aluminum tube, and the flat tube microchannel heat exchange tube 2 is a hollow pipe structure, the flat tube microchannel heat exchange tube Two sets of heat exchange grids 5 are arranged in the cavity of 2.

[0027] The thickness H of the aluminum plate 1 is 3.0mm, and the outer edges of the upper and lower ends of the aluminum plate 1 protrude from the outer edges of the upper and lower ends of the insulation layer 3, and the outer edges of the upper and lower ends of the aluminum plate 1 protrude from the outer edges. Fi...

Embodiment 2

[0030] The difference between this embodiment and embodiment 1 is:

[0031] The material of the insulation layer 3 is plastic;

[0032] Three flat tube microchannel heat exchange tubes 2 are arranged between the aluminum plate 1 and the insulation layer 3, and three sets of heat exchange grids 5 are arranged in the cavity of the flat tube microchannel heat exchange tube 2;

[0033] The thickness H of the aluminum plate 1 is 8.0 mm, and the thickness h of the flat tube microchannel heat exchange tube 2 is 8.0 mm.

Embodiment 3

[0035] The difference between this embodiment and embodiment 1 is:

[0036] Three flat tube microchannel heat exchange tubes 2 are arranged between the aluminum plate 1 and the insulation layer 3, and four sets of heat exchange grids 5 are arranged in the cavity of the flat tube microchannel heat exchange tube 2;

[0037] The thickness H of the aluminum plate 1 is 5.0 mm, and the thickness h of the flat tube microchannel heat exchange tube 2 is 6.0 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com