Lightweight high-strength cement based composite material

A composite material, cement-based technology, applied in the field of concrete, can solve the problems of poor workability and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

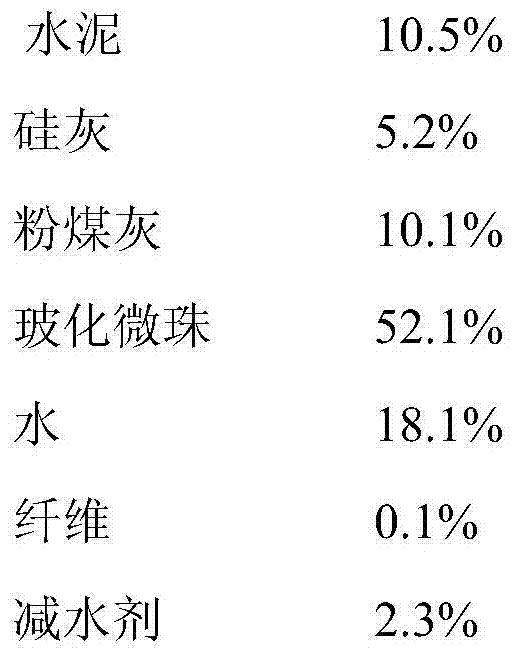

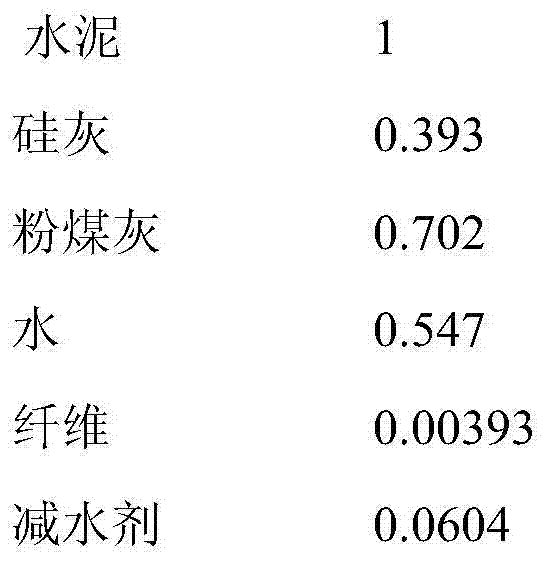

Embodiment 1

[0066] Lightweight high-strength cement-based composite material, including cementitious material, lightweight aggregate, water, fiber and water reducer, the cement is P·O cement with a strength grade of 42.5, and the mineral admixture is silica fume and powder Coal ash, the light aggregate used has a particle size of 0.5-2mm and an apparent density of 95kg / m 3 vitrified microbeads.

[0067] The ratio fraction of cement, silica fume and fly ash is numerically analyzed and calculated through the ideal accumulation curve and its particle size cumulative distribution curve;

[0068] 1) The ideal stacking curve formula is:

[0069] P sd 100 · / m / ;

[0070] Among them, P sd is the percentage of particles passing through the sieve, A is an empirical constant, d is the diameter of the sieve, D max is the maximum particle size of the particle;

[0071] The value of the empirical constant A is determined by the formula according to the design slump or design expansion r...

Embodiment 2

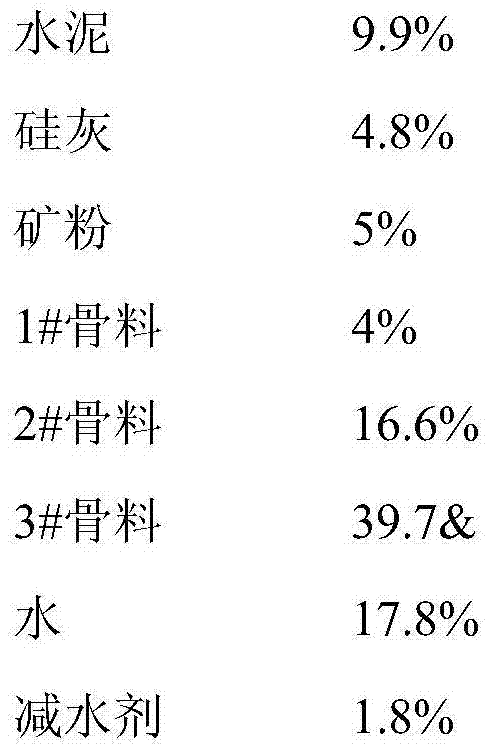

[0096] Lightweight high-strength cement-based composite material, including cementitious material, aggregate, water, water reducer and thickener, the cement is P·II cement with a strength grade of 52.5, and the mineral admixture is silica fume and Mineral powder, the proportion of each component of cementitious material is by the calculation method of embodiment 1, gets X c =0.503,X sf =0.244,X bs =0.254;

[0097] The aggregates used include:

[0098] 1# aggregate: natural river sand with a fineness modulus of 2.7;

[0099] 2# aggregate: the particle size is 0.5~2mm and the apparent density is 95kg / m 3 vitrified microbeads;

[0100]3# aggregate: the particle size is 5-10mm and the apparent density is 500kg / m 3 Light shale ceramsite;

[0101] The ratio of aggregates is numerically analyzed and calculated through ideal stacking curves and cumulative distribution curves of various aggregates;

[0102] 1) The accumulation curve formula is:

[0103] P dA B 100 B d A / D ...

Embodiment 3

[0126] Lightweight high-strength cement-based composite material, including cementitious material, aggregate, water, water reducing agent and shrinkage reducing agent, the cement is P·II cement with a strength grade of 62.5, and the mineral admixture is silica fume and ore Powder, the proportion of each component of the cementitious material is by the calculation method of embodiment 1, gets X c =0.774, X sf =0.122,X bs =0.104; the aggregate is natural river sand with a fineness modulus of 2.7 and a particle size of 5-10mm with an apparent density of 550kg / m 3 Lightweight fly ash ceramsite, the proportioning fraction of each component of aggregate is according to the calculation method of embodiment 2, gets X s1 =0.192,X s2 =0.808; the volume ratio of aggregate to cementitious material is 0.943; the water-binder ratio is 0.159; the admixture is polycarboxylate water reducer solution, and the dosage is 1.5% of the mass of cementitious material; the thickener is methyl cellul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com