Method for measuring stressed deformation of cement-base composite material

A composite material and detection method technology, applied in the direction of material resistance, using stable tension/pressure to test material strength, etc., can solve problems such as uneven shrinkage cracks, and achieve the effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Embodiment 1: 1, sample preparation

[0094] 1), polypropylene fine denier short fiber reinforced cement mortar

[0095] Ratio: cement: standard sand: water = 1:2.5:0.44

[0096] Dosage of polypropylene fine denier short fibers:

[0097] Polypropylene fine denier short fiber: cement mortar = 1:1000 (volume ratio)

[0098] Stirring time: cement + fiber 1.5min

[0099] Cement + fiber + standard sand + water 3min

[0100] Vibration time; 2min

[0101] The standard curing time is 24 hours, demoulding, and natural curing for 28 days.

[0102] 2), the surface of the sample is coated with a conductive film

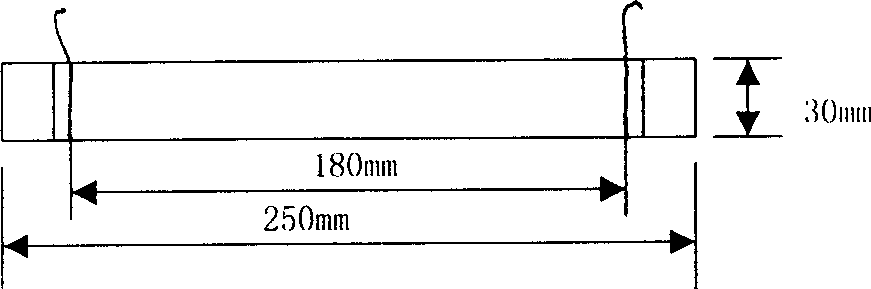

[0103] After the cement mortar and the polypropylene fine-denier short-fiber-reinforced cement mortar are naturally cured to age, the surface of the sample is treated with conductive adhesive to form a conductive film sensor, as shown in Figure (8). Figure (8) is a schematic diagram of a mortar sample coated with a conductive film on the surface.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com