Cement-based composite material and pressure sensor made of same

A pressure-sensitive sensor and composite material technology, applied in the field of graphene oxide and carbon fiber cement-based composite materials and their preparation, can solve the problem of poor resistivity and stress sensing ability, low sensitivity and stable pressure-sensitive sensor of carbon fiber dispersed cement-based composite materials Poor performance and other problems, to achieve the effect of good compactness, high sensitivity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

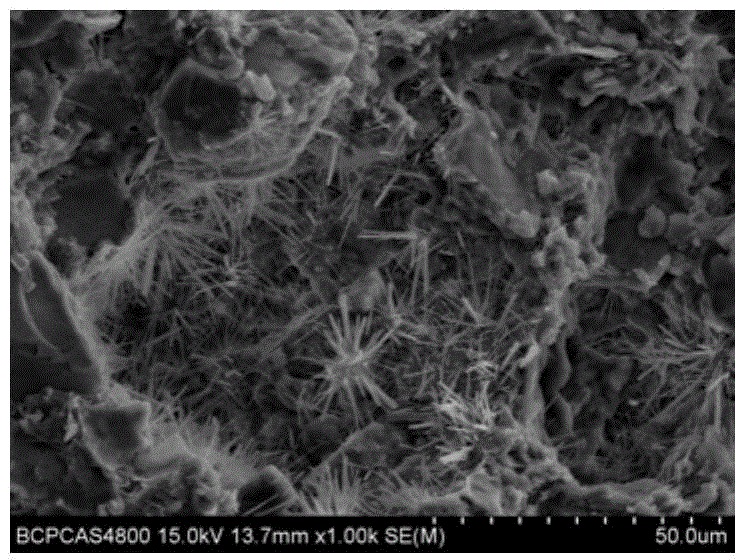

[0031] Example 1 Preparation of graphene oxide and carbon fiber cement-based composite pressure-sensitive sensor

[0032] Add 1% polycarboxylate superplasticizer by cement mass and 0.03% graphene oxide solution into 200ml water and stir evenly, then add 0.3% cement mass HNO 3The oxidized chopped carbon fiber is fully stirred, and defoaming agent is added to defoam; the uniformly dispersed carbon fiber and cement are poured into a mortar mixer and stirred evenly. During this process, the remaining water and an appropriate amount of water reducer are added to control The consistency and fluidity of the mixture. After mixing evenly, inject 40×40×160mm plastic sand into a standard mechanical test mold (pre-placed with copper wire mesh electrodes), vibrate on a vibrating table for 3 minutes, place it indoors, demould after 1 day, and perform standard maintenance.

Embodiment 2

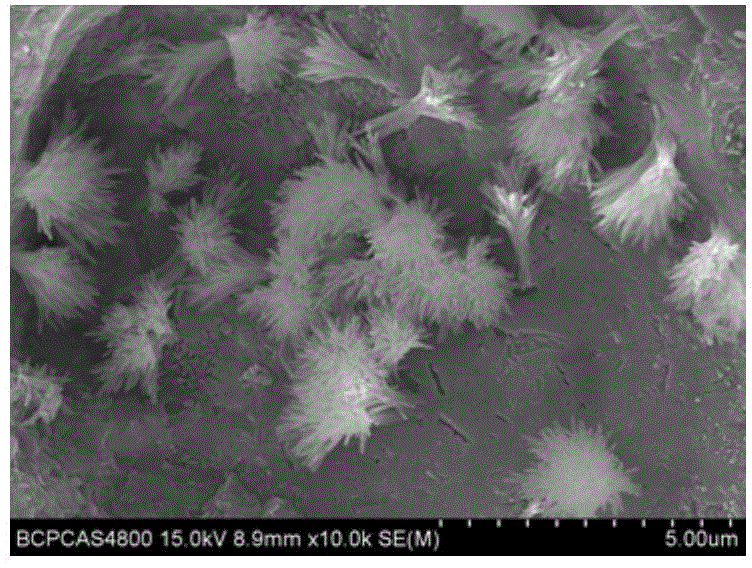

[0033] Example 2 Preparation of graphene oxide / carbon fiber cement-based composite material pressure-sensitive sensor

[0034] Add 1.2% of cement mass polycarboxylate superplasticizer and 0.1% graphene oxide solution into 200ml water and stir evenly, then add 1% cement mass through HNO 3 Oxidized short-cut carbon fiber, stir well to disperse the carbon fiber evenly, and add defoamer to defoam; pour the uniformly dispersed carbon fiber and cement into the mortar mixer and stir evenly, during this process, add the remaining water and an appropriate amount of Water reducer, control the consistency and fluidity of the mixture. After mixing evenly, inject 40×40×160mm plastic sand into a standard mechanical test mold (pre-placed with copper wire mesh electrodes), vibrate on a vibrating table for 3 minutes, place it indoors, demould after 1 day, and perform standard maintenance.

Embodiment 3

[0035] Example 3 Preparation of graphene oxide and carbon fiber cement-based composite pressure-sensitive sensor

[0036] Add 1.6% of cement mass polycarboxylate superplasticizer and 1% graphene oxide solution into 200ml water and stir evenly, then add 2% cement mass through HNO 3 The oxidized carbon fiber is fully stirred to disperse the carbon fiber evenly, and defoaming agent is added to defoam; the uniformly dispersed carbon fiber and cement are poured into a mortar mixer and stirred evenly. During this process, add the remaining water and an appropriate amount of water agent to control the consistency and fluidity of the mixture. After mixing evenly, inject 40×40×160mm plastic sand into a standard mechanical test mold (pre-placed with copper wire mesh electrodes), vibrate on a vibrating table for 3 minutes, place it indoors, demould after 1 day, and perform standard maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com