Pressure-sensitive cement-base composite material

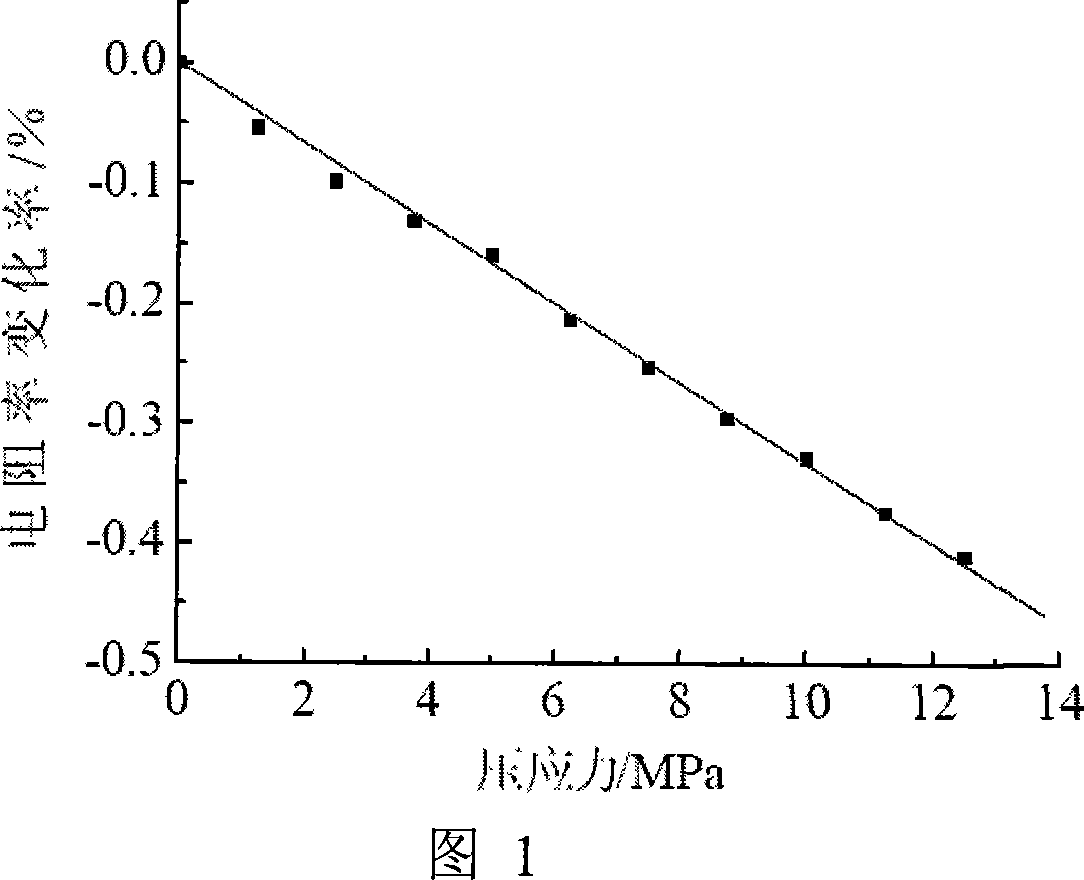

A technology for cement-based materials and composite materials, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of being greatly affected by humidity, low sensitivity of force-electric coupling effect, and matrix polarization easily affecting electricity Signal test and other problems, to achieve the effect of low humidity and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0009] Embodiment 1: The pressure-sensitive cement-based composite material of this embodiment is composed of a functional component and a cement-based material, the functional component is nickel powder, and the cement-based material is a cementitious material or a composite material of a cementitious material and aggregate; The functional components account for 1-80% of the total weight, and the rest are cement-based materials.

specific Embodiment approach 2

[0010] Embodiment 2: This embodiment differs from Embodiment 1 in that the functional components account for 40-70% of the total weight. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Embodiment 3: This embodiment differs from Embodiment 1 in that the functional components account for 55% of the total weight. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com