Quick-hardening high-early strength concrete-based composite material for maritime work

An early-strength cement and composite material technology, applied in the field of building materials, can solve the problems of slow strength development of ordinary Portland cement, unfavorable water conservation, and increased construction costs, etc., achieve high early strength, reduce transportation volume, and avoid corrosion damage Effect

Inactive Publication Date: 2010-05-19

LOGISTICAL ENGINEERING UNIVERSITY OF PLA

View PDF1 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because desalination of sea sand needs to consume a certain amount of fresh water resources, and the cost is high, which increases the construction cost, and the fresh water for mixing needs to be transported from land, which also increases the construction cost, which is not conducive to saving water

In addition, the strength of ordinary Portland cement develops slowly and the maintenance period is long, which is not conducive to construction in the harsh and abrupt environment of the island

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment 1~5

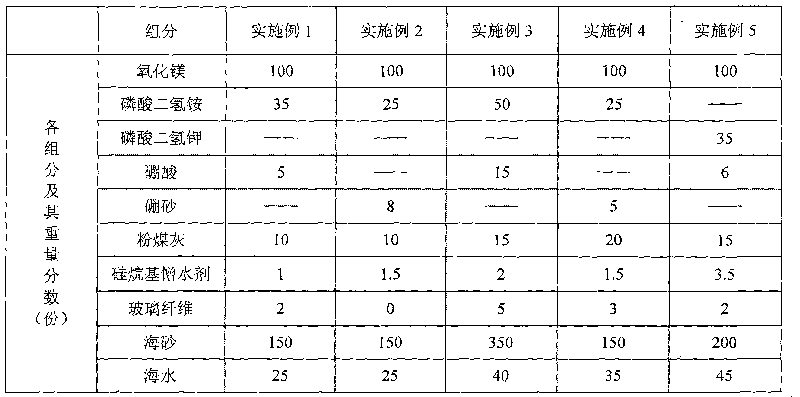

[0030] Concrete embodiment 1~5, see table 1.

[0031] Table 1: the formula of specific embodiment of the present invention

[0032]

[0033] Note: the specific surface area of the magnesium oxide in Examples 1 to 5 is: 3000cm 2 / g, 3500cm 2 / g, 4500cm 2 / g, 3500cm 2 / g, 4000cm 2 / g. The fineness modulus of sea sand is: 2.7, 1.5, 3.2, 3.2, 2.7.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a quick-hardening high-early strength concrete-based composite material for a maritime work, which mainly comprises the following components in parts by weight: 100 parts of magnesium oxide, 25-50 parts of phosphate, 5-15 parts of retarder, 0.5-3.5 parts of siloyl group moisture repellent, 10-20 parts of flyash, 0-5 parts of glass fibre, 150-350 parts of sea sands and 25-50 parts of seawater. The invention takes the sea sands without desalting treatment as aggregate and the seawater as mixing water, thereby fully utilizing island resources such as sea sands, seawater, and the like, greatly reducing traffic capacity, saving cost. In addition, the invention has the advantages of quick setting and hardening, high early strength, good seawater erosion capability, and the like, thereby being widely applied to quick repatching and building in projects such as island roads, landingstrips, docks, and the like.

Description

technical field [0001] The invention relates to a building material, in particular to a fast-hardening and early-strength cement-based composite material for marine engineering, which can be used for rapid repair and construction of road surfaces on islands or seaport wharves. Background technique [0002] With the continuous development and utilization of marine resources, there will be more and more civil engineering projects at sea and on islands and reefs, but currently the marine concrete used on seas and islands and reefs mainly uses Portland cement. A large amount of mineral powder, fly ash, silica fume and water are added to it. Due to the lack of conventional building materials such as river sand and gravel on the sea and on islands and reefs, and the lack of fresh water for construction, if it is shipped by land, the transportation volume is limited and the cost is high. Sea sand is an important building material. However, because sea sand contains a large amount ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/34C04B14/06

CPCC04B2103/20C04B2103/12C04B2111/24C04B2111/74C04B2111/0075C04B2111/72C04B2103/0009C04B2103/14C04B2103/0007C04B28/344Y02W30/91C04B14/068C04B14/304C04B14/42C04B18/08C04B22/0026C04B2103/65C04B24/42C04B22/0013

Inventor 曹巨辉汪宏涛

Owner LOGISTICAL ENGINEERING UNIVERSITY OF PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com