Construction Method of Embedded Square Concrete Steel Tube Concrete Ring Beam-Construction Column in Masonry Structure

A technology of masonry structure and construction method, which is applied in the construction of embedded square steel pipe concrete ring beam-construction column in masonry structure, the field of ground floor and multi-layer masonry structure construction, and can solve the irregular design and pouring of ring beam structural column, Only partial use of ring-beam structural columns fails to meet the requirements of seismic fortification, etc., so as to save maintenance time, reduce the amount of steel and concrete, and ensure the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

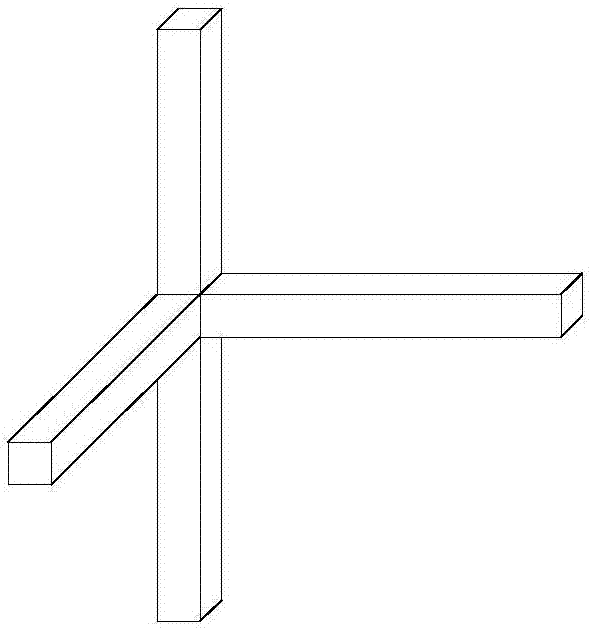

[0042] A method for constructing an embedded square steel tube concrete L-shaped ring beam-construction column in a masonry structure, comprising the following steps:

[0043] Step 1. When building the foundation, set ≥ 4 structural columns on the ground circle beam or stone foundation to connect the inserted bars (the number and diameter of the inserted bars should be determined according to the actual situation of the house in accordance with the requirements of the reinforced concrete structure), and the length of the inserted bars refers to the current According to Article 8.3 of the "Code for Design of Concrete Structures" (GB50010-2010), the tie-up stirrups are arranged along the length of the inserted bars to form a reinforcement cage (the side length of the stirrups ≤ the side length of the square steel pipe -10mm~20mm), and the steel cage is covered Into 120mm×120mm square steel pipe;

[0044] Step 2. Build a 240mm or 370mm thick brick wall or block wall, wrap the squ...

Embodiment 2

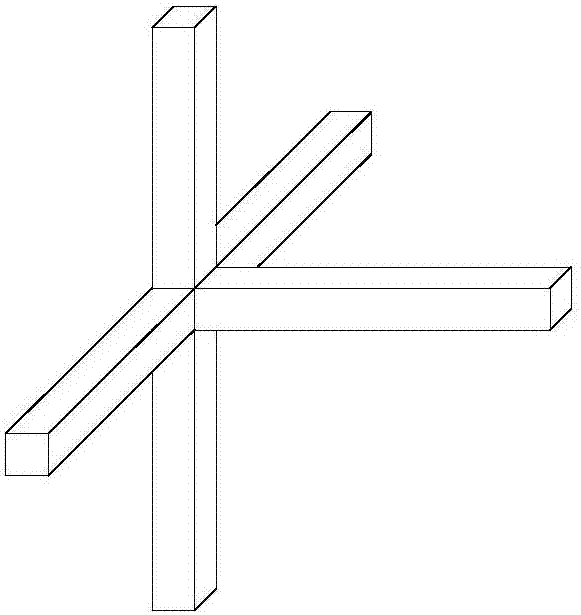

[0047] A method for constructing an embedded square steel tube concrete T-shaped ring beam-construction column in a masonry structure, comprising the following steps:

[0048] Step 1. When building the foundation, set ≥ 4 structural columns on the ground circle beam or stone foundation to connect the inserted bars (the number and diameter of the inserted bars should be determined according to the actual situation of the house in accordance with the requirements of the reinforced concrete structure), and the length of the inserted bars refers to the current According to Article 8.3 of the "Code for Design of Concrete Structures" (GB50010-2010), the tie-up stirrups are arranged along the length of the inserted bars to form a reinforcement cage (the side length of the stirrups ≤ the side length of the square steel pipe -10mm~20mm), and the steel cage is covered Into 120mm×120mm square steel pipe;

[0049] Step 2. Build a 240mm or 370mm thick brick wall or block wall, wrap the squ...

Embodiment 3

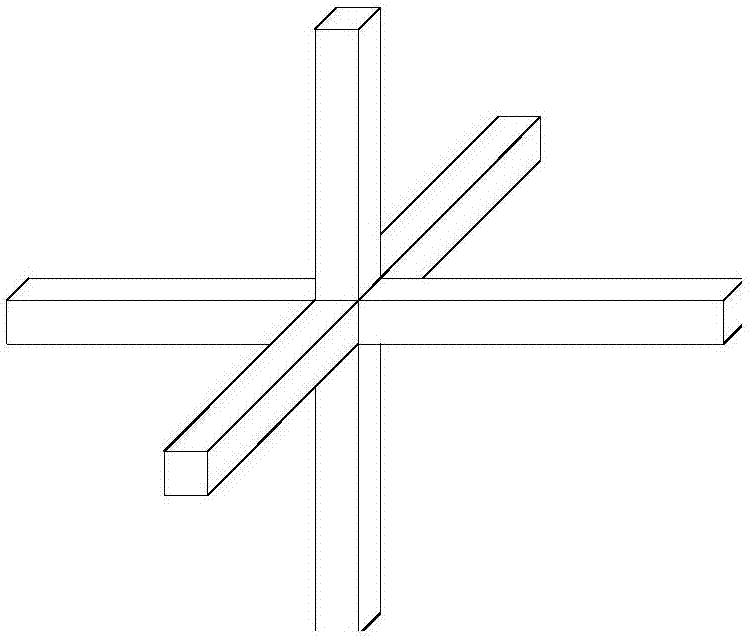

[0052] A method for constructing a masonry structure embedded square steel tube concrete cross-shaped ring beam-structural column, comprising the following steps:

[0053] Step 1. When building the foundation, set ≥ 4 structural columns on the ground circle beam or stone foundation to connect the inserted bars (the number and diameter of the inserted bars should be determined according to the actual situation of the house in accordance with the requirements of the reinforced concrete structure), and the length of the inserted bars refers to the current According to Article 8.3 of the "Code for Design of Concrete Structures" (GB50010-2010), the tie-up stirrups are arranged along the length of the inserted bars to form a reinforcement cage (the side length of the stirrups ≤ the side length of the square steel pipe -10mm~20mm), and the steel cage is covered Into 120mm×120mm square steel pipe;

[0054] Step 2. Build a 240mm or 370mm thick brick wall or block wall, wrap the square ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com