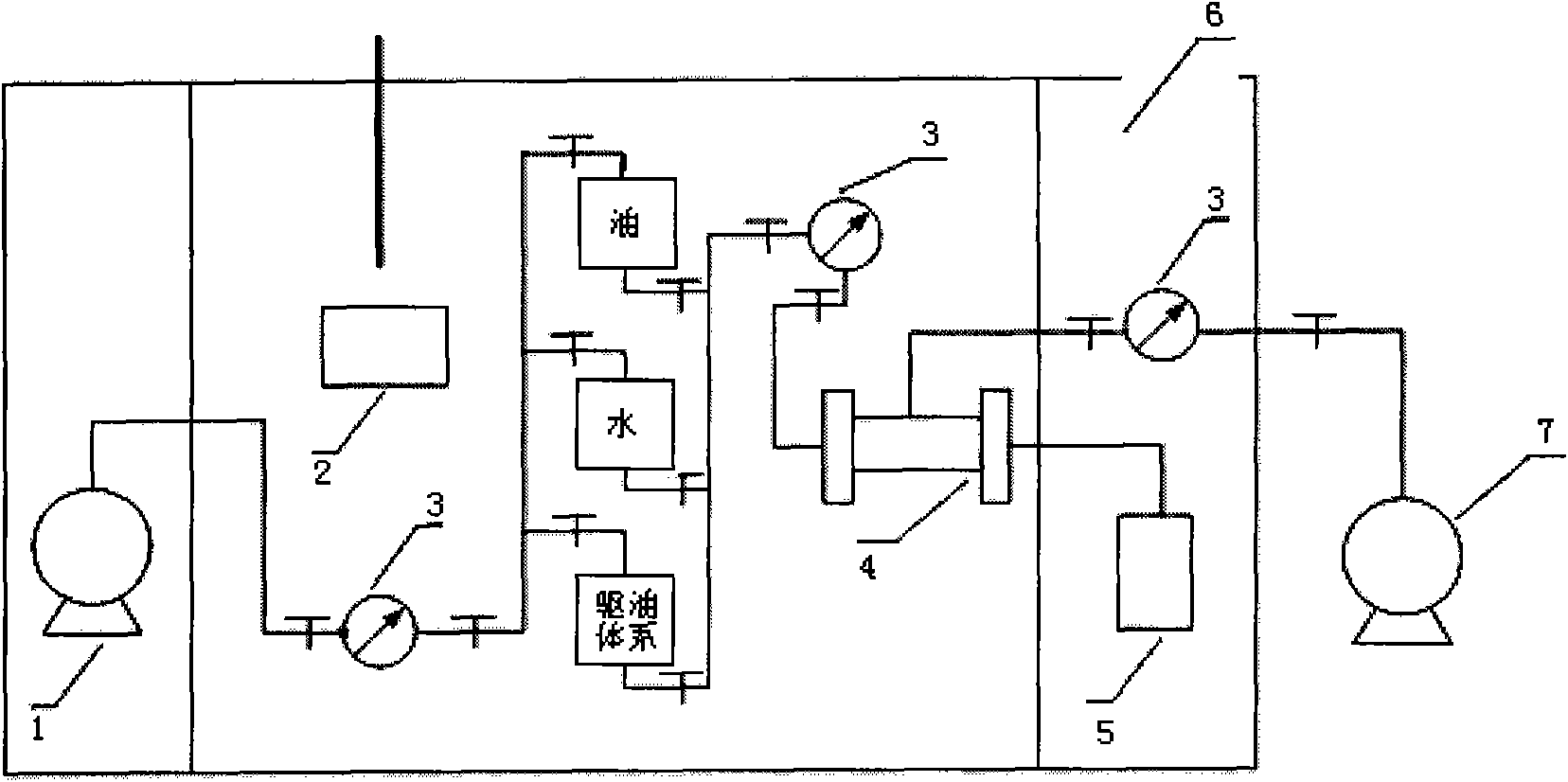

Fluorocarbon surfactant binary composite foam flooding system

A fluorocarbon surface and binary composite technology, which is applied in the direction of production fluid, drilling composition, wellbore/well components, etc., can solve the problem that foam flooding cannot be fully applied, cannot withstand high temperature and high salt, and has poor oil resistance, etc. problems, to achieve foam stability, strong oil resistance, excellent hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

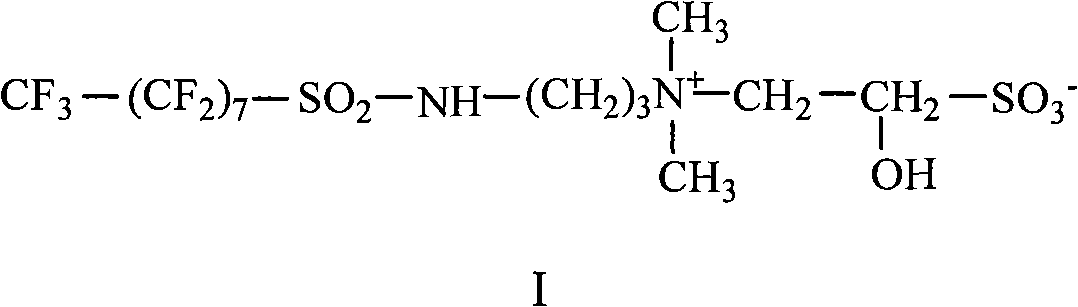

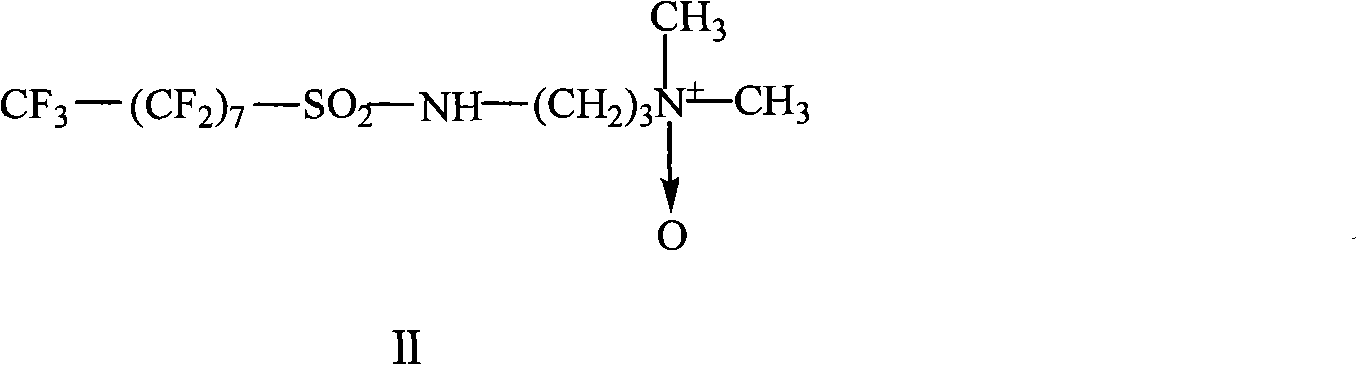

[0060] [Example 1] The composition of the oil displacement system is as follows: the foaming agent is a combination of sulfobetaine type fluorocarbon surfactant (FS) and α-alkenyl sulfonate (AOS) in a weight ratio of 1:5. The total mass of the system solution is the base number, the concentration of the foaming agent is 0.2wt%; the foam stabilizer is partially hydrolyzed polyacrylamide (HPAM), the molecular weight is 10 million, the degree of hydrolysis is 25%, and the dosage is 1000 mg / L.

[0061] The rest is water.

[0062] The above oil displacement system is abbreviated as: FS:AOS=1:5 (0.2wt%)+HPAM 1000mg / L. The same expressions are also used in the following embodiments, and the meanings are the same as those in this embodiment. This expression is a general expression in the art.

[0063] The above flooding system is used for indoor foam flooding. Crude oil: dehydrated crude oil from Liaohe United Station, viscosity of 950mPa·s at 45°C; viscosity at room temperature: 20...

Embodiment 2

[0065] [Embodiment 2] As described in Embodiment 1, the difference is:

[0066] The oil displacement system FS:AOS=1:5(0.2wt%)+HPAM 500mg / L, the permeability of sand filling pipe k: 360.4md, the water flooding recovery rate is 47.8%, and the enhanced oil recovery rate is 30.9%.

Embodiment 3

[0067] [Embodiment 3] As described in Embodiment 1, the difference is:

[0068] The oil displacement system FS:AOS=1:5(0.1wt%)+HPAM 1000mg / L, the permeability of sand-packing pipe k: 420md, the water flooding recovery rate is 50.5%, and the enhanced oil recovery rate is 29.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com